automic water softener system with FRP tank

- Delivery Time:

- 5 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China (Mainland) |

|---|

Product Description

Product Description

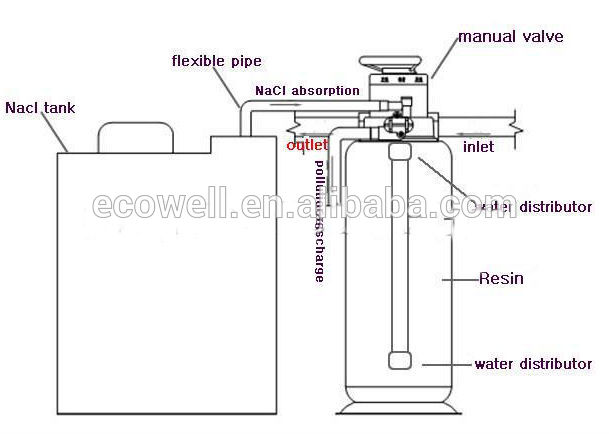

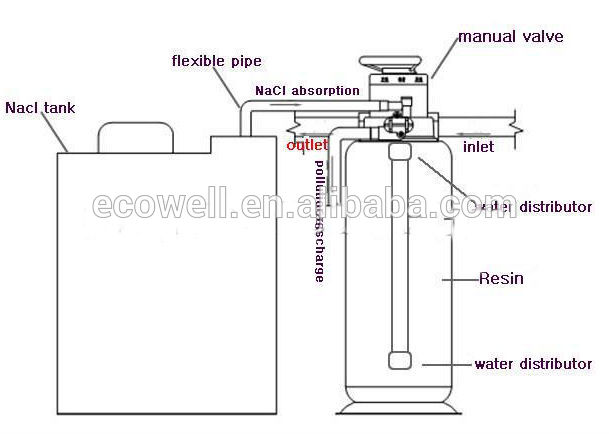

automic water softener system with FRP tank Picture:

Specification:

Specification:

1, the feed water pressure: 0.2 ~ 0.5 Mpa

2, raw water hardness: < 12 tendency/L (when raw water hardness > 8 tendency for L, should be based on different regional water quality do special design)

3, water hardness: < 0.03 tendency for L (reach the national water quality standard of low pressure boiler GB1576-2001);

4, raw water salinity < 1500 mg/L, turbidity < 5 iron < 0.3 mg/L

5, power supply: ~ 220 v, 50 hz

6, salt consumption of < 100 g/gram equivalent (related to raw water hardness);

7, water consumption < 2%;Power consumption < 50 w

Automatic softening water equipment according to the different methods of regeneration control is divided into time control and flow control of two types:

1, time control, time control is to point to when the equipment operation to start automatically when setting the regeneration time of regeneration process;This type of system is based on the actual water consumption and regeneration equipment exchange ability to set time, the user can chose regeneration process in water consumption in less time, can also according to the need to manually start the regeneration process at any time.

Time control advantages: 1) cheap;2) easy to operate

Time control weakness: 1) general once every 24 hours to regeneration;Regeneration (or 12 hours, need to do special design; 2) can't be used according to actual situation accurately determine the timing of the regeneration;

Applicable occasions: time control general application in the low hardness (< 4 tendency/L), water stability, water fluctuation is less than 10%), the water requirement is not high, less water consumption.

2, flow control, flow control is based on equipment exchange capacity (output) to set the finish operation.Equipment run time by special meter on the water flow statistics.When the total water yield to set the amount of water, controller will automatically start the regeneration process.Setting should be according to the resin before total loading quantity, total output of each cycle of water, water hardness calculated according to the value set (MG960 series of water rate is calculated by the controller automatically).When to set the amount of water, can be regenerated according to need to immediately or wait until after a set time to regenerate. Abous us:

Specification:

Specification:1, the feed water pressure: 0.2 ~ 0.5 Mpa

2, raw water hardness: < 12 tendency/L (when raw water hardness > 8 tendency for L, should be based on different regional water quality do special design)

3, water hardness: < 0.03 tendency for L (reach the national water quality standard of low pressure boiler GB1576-2001);

4, raw water salinity < 1500 mg/L, turbidity < 5 iron < 0.3 mg/L

5, power supply: ~ 220 v, 50 hz

6, salt consumption of < 100 g/gram equivalent (related to raw water hardness);

7, water consumption < 2%;Power consumption < 50 w

Automatic softening water equipment according to the different methods of regeneration control is divided into time control and flow control of two types:

1, time control, time control is to point to when the equipment operation to start automatically when setting the regeneration time of regeneration process;This type of system is based on the actual water consumption and regeneration equipment exchange ability to set time, the user can chose regeneration process in water consumption in less time, can also according to the need to manually start the regeneration process at any time.

Time control advantages: 1) cheap;2) easy to operate

Time control weakness: 1) general once every 24 hours to regeneration;Regeneration (or 12 hours, need to do special design; 2) can't be used according to actual situation accurately determine the timing of the regeneration;

Applicable occasions: time control general application in the low hardness (< 4 tendency/L), water stability, water fluctuation is less than 10%), the water requirement is not high, less water consumption.

2, flow control, flow control is based on equipment exchange capacity (output) to set the finish operation.Equipment run time by special meter on the water flow statistics.When the total water yield to set the amount of water, controller will automatically start the regeneration process.Setting should be according to the resin before total loading quantity, total output of each cycle of water, water hardness calculated according to the value set (MG960 series of water rate is calculated by the controller automatically).When to set the amount of water, can be regenerated according to need to immediately or wait until after a set time to regenerate. Abous us:

Related Keywords

Related Keywords

You May Also Like

You May Also Like