BUFLEX DGR Cable Control and Power Reeling Cables 0.6 / 1 (1.2) kV

- Delivery Time:

- 10 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Guangdong, China (Mainland) |

|---|

Product Description

Product Description

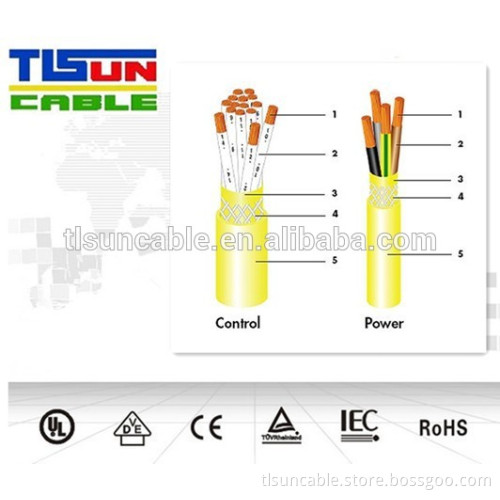

BUFLEX DGR Cable Control and Power Reeling Cables 0.6 / 1 (1.2) kV Product Description Applications Cables with reinforced polyurethan sheath, especially designed for reeling applications.

Due to high mechanical properties of PUR, Buflex cables could be used in hard conditions as quarries, mines … Design 1. Conductor

Flexible plain copper, class 5 IEC 60228 2. Insulation

XLPE 3. Filler + Inner Sheath 4. Reinforcement

Anti twist element 5. Outer sheath

PUR Colour: yellow Marking BUFLEX DGR – 0.6/1 kV

Number of cores – cross-section

NEXANS – year – week Cores Identification Control: white with printed numbers Power:

4 cores: black – brown – grey – green/yellow (3 earth cores for sizes ≥ 25 mm2)

5 cores: black – brown – grey – blue – green/yellow Mechanical properties

Chemical properties Oil resistant.

For outdoor applications. Moisture, UV and ozone resistance. Electrical and Thermal properties

Due to high mechanical properties of PUR, Buflex cables could be used in hard conditions as quarries, mines … Design 1. Conductor

Flexible plain copper, class 5 IEC 60228 2. Insulation

XLPE 3. Filler + Inner Sheath 4. Reinforcement

Anti twist element 5. Outer sheath

PUR Colour: yellow Marking BUFLEX DGR – 0.6/1 kV

Number of cores – cross-section

NEXANS – year – week Cores Identification Control: white with printed numbers Power:

4 cores: black – brown – grey – green/yellow (3 earth cores for sizes ≥ 25 mm2)

5 cores: black – brown – grey – blue – green/yellow Mechanical properties

| Max. tensile load | 20 N/mm2 of copper cross section |

| Tests | Bending test, torsional test |

| Reeling speed | up to 120 m/min (for higher speed contact us) |

For outdoor applications. Moisture, UV and ozone resistance. Electrical and Thermal properties

| Nominal voltage | Uo/U | 0.6/1 kV |

| Maximum operating voltage in AC systems | Um | 1.2 kV |

| Test voltage: | ||

| - Power | 3.5 kV in AC | |

| - Control | 2.5 kV in AC | |

| Current rating (A) | see electrical characteristics page 3.2 B | |

| Max. temperature at the conductor : | ||

| - in service | + 90 °C | |

| - under short circuit conditions | + 250 °C | |

| Max. surface temperature : | ||

| - fixed installation | - 40 °C up to + 80 °C | |

| - mobile operation | - 30 °C up to + 80 °C | |

| Number of cores and nominal cross-section | Outer diameter | Weight approx. | Max. tensile load | ||

| (mm2) | Min. (mm) | Max. (mm) | (kg/km) | (N) | |

| POWER | 4 G 2.5* | 10 | 11.5 | 180 | 200 |

| 4 G 4* | 11.5 | 13 | 260 | 320 | |

| 4 G 6* | 13 | 14.5 | 370 | 480 | |

| 4 G 10* | 15.5 | 17 | 580 | 800 | |

| 4 G 16* | 19.5 | 21.5 | 920 | 1,280 | |

| 3 x 25 + 3 G 6* | 23.5 | 25.5 | 1,240 | 1,800 | |

| 3 x 35 + 3 G 6* | 27 | 29.5 | 1,640 | 2,400 | |

| 3 x 50 + 3 G 10* | 30 | 32.5 | 2,240 | 3,600 | |

| 3 x 70 + 3 G 16* | 35 | 37.5 | 3,100 | 5,100 | |

| 3 x 95 + 3 G 16* | 39 | 42 | 3,890 | 6,600 | |

| 3 x 120 + 3 G 25* | 44 | 47 | 5,080 | 8,700 | |

| 3 x 150 + 3 G 25* | 49 | 52.5 | 6,160 | 10,500 | |

| 3 x 185 + 3 G 35 | 54.5 | 58.5 | 7,680 | 13,200 | |

| 3 x 240 + 3 G 50 | 60.5 | 64.5 | 9,870 | 17,400 | |

| 3 x 300 + 3 G 50 | 68.5 | 72.5 | 12,300 | 21,000 | |

| 5 G 2.5 | 11 | 12.5 | 220 | 250 | |

| 5 G 4 | 13 | 14.5 | 320 | 400 | |

| 5 G 6* | 15 | 16.5 | 450 | 600 | |

| 5 G 10 | 18 | 20 | 700 | 1,000 | |

| 5 G 16* | 22 | 24 | 1,100 | 1,600 | |

| 5 G 25 | 27 | 29.5 | 1,550 | 2,500 | |

| 5 G 35 | 31 | 33.5 | 2,050 | 3,500 | |

| CONTROL | 7 x 1.5 | 11.5 | 13 | 210 | 210 |

| 12 x 1.5 | 16 | 17.5 | 330 | 360 | |

| 18 x 1.5 | 16 | 17.5 | 410 | 540 | |

| 24 x 1.5 | 19 | 21.5 | 680 | 720 | |

| 36 x 1.5 | 22 | 24 | 900 | 1,080 | |

| 7 x 2.5 | 12.5 | 14 | 30 | 350 | |

| 12 x 2.5* | 18.5 | 20.5 | 610 | 600 | |

| 18 x 2.5* | 18.5 | 20.5 | 740 | 900 | |

| 24 x 2.5 | 22.5 | 24.5 | 1,050 | 1,200 | |

| 36 x 2.5* | 25 | 28 | 1,430 | 1,800 | |

| 42 x 2.5 | 27 | 29.5 | 1,500 | 2,100 | |

| 26 x 2.5 + (4 x 2.5)C* | 24.5 | 27 | 1,260 | 1,500 | |

Related Keywords

Related Keywords