Rite Mfg custom stainless steel cnc lathe machine parts

- Delivery Time:

- 30 Days

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong, China (Mainland) |

|---|

CNC Turning | φ0.5 - φ300 * 750 mm | +/-0.005 mm |

CNC Milling | 510 * 1020 * 500 mm(max) | +/-0.01 mm |

CNC Stamping | 1000 * 1000 mm(max) | +/-0.05 mm |

Drawing Format | Auto CAD, Solid works, Pro/E, PDF. | |

Test Equipment | D measurement instrument, Projector, CMM, Altimeter, Micrometer, Thread Gages, Calipers, Pin Gauge etc. | |

Stainless Steel | SS201,SS301, SS303, SS304, SS316, SS416 etc. |

Steel | mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45# etc. |

Brass | HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. |

Copper | C11000,C12000,C12000 C36000 etc. |

Aluminum | AL6061, Al6063, AL6082, AL7075, AL5052, A380 etc. |

Iron | 1213, 12L14, 1215 etc. |

Plastic | ABS, PC, POM, Delrin, Nylon, Teflon, PP, Peek etc. |

Aluminum parts | Stainless Steel parts | Steel | Plastic |

Clear Anodized | Polishing | Zinc plating | Plating gold (ABS) |

Color Anodized | Passivating | Oxide black | Painting |

Sandblast Anodized | Sandblasting | Nickel plating | Brushing (Acylic) |

Chemical Film | Laser engraving | Chrome plating | Laser engraving |

Brushing | Carburized | ||

Polishing | Hot treatment | ||

Chroming | Powder Coated |

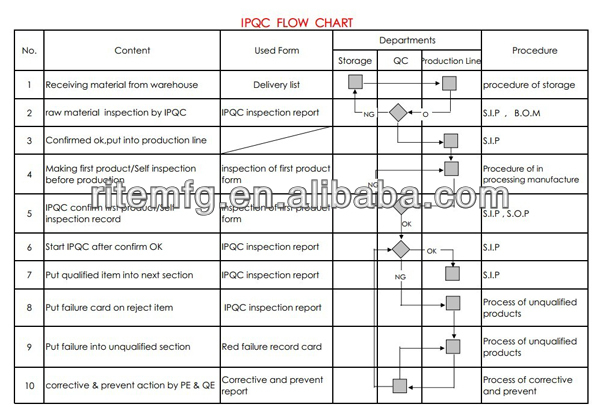

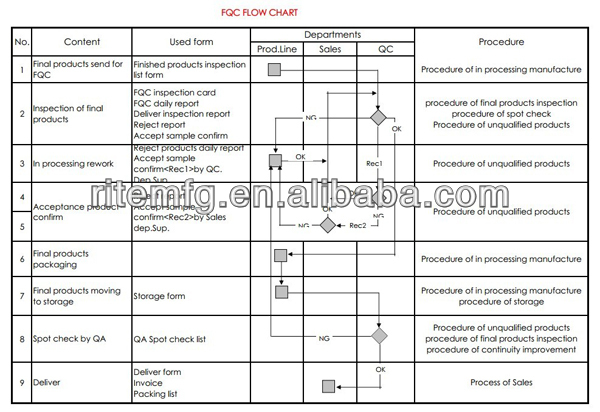

QA quality control

QA quality control  QA Flow Chart

QA Flow Chart

Package

Package  Why Us? • Design assistance and full engineering support • 8 years' experience working with OEM's for aluminum • One stop manufacturing includes sourcing of subcomponents and hardware overseas pa rtners • Complete production lines for custom turning, milling, cnc machining sheet metal fabricati on, stamping, bending, argon welding and surface finish • Anodize and power coating finish with all kinds of customized colors • Advanced machine tools, CAD/CAM programming software • Prototype machining capabilities • Strict quality control standards with a highly qualified inspection department • Continually upgrading and advancing our equipment to remain competitive • Extensive capacity — We can run 24 hours, 6 days a week • Our main goal is TOTAL CUSTOMER SATISFACTION while making your job easy! Additional Information: For more information, please contact us freely, and your inquiry will be replied within 8 hours. Company: Rite Metal Products Co., Ltd. 3F, No.18, Jinsha 2nd Road, Shajing Twon, Baoan District,Shenzhen , China Tel: +86-755-81453453 Fax: +86-755-81453460 Web:www.ritemfg.com YOU TAKE, WE CARE.

Why Us? • Design assistance and full engineering support • 8 years' experience working with OEM's for aluminum • One stop manufacturing includes sourcing of subcomponents and hardware overseas pa rtners • Complete production lines for custom turning, milling, cnc machining sheet metal fabricati on, stamping, bending, argon welding and surface finish • Anodize and power coating finish with all kinds of customized colors • Advanced machine tools, CAD/CAM programming software • Prototype machining capabilities • Strict quality control standards with a highly qualified inspection department • Continually upgrading and advancing our equipment to remain competitive • Extensive capacity — We can run 24 hours, 6 days a week • Our main goal is TOTAL CUSTOMER SATISFACTION while making your job easy! Additional Information: For more information, please contact us freely, and your inquiry will be replied within 8 hours. Company: Rite Metal Products Co., Ltd. 3F, No.18, Jinsha 2nd Road, Shajing Twon, Baoan District,Shenzhen , China Tel: +86-755-81453453 Fax: +86-755-81453460 Web:www.ritemfg.com YOU TAKE, WE CARE. Related Keywords