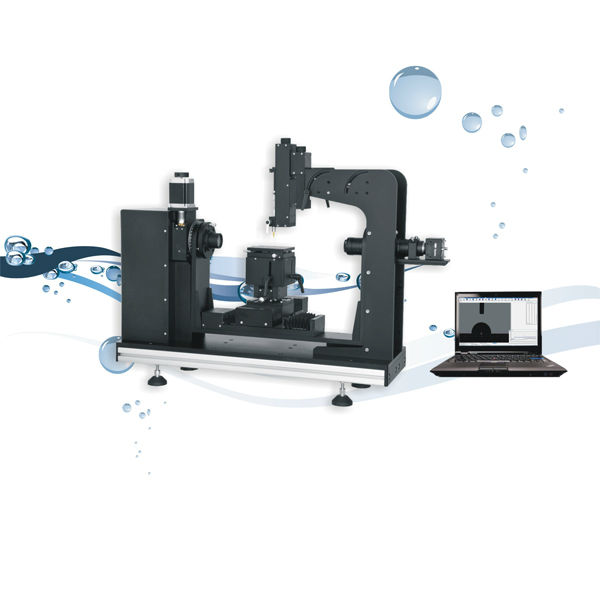

Excellent Drop Shape Analysis and Measurement System C60

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shanghai, China (Mainland) |

|---|

4 generation ADSA

Parallel light&telecentric lens

Excellent Drop Shape Analysis and Measurement System C60

C60 is drop shape analysis based system which focuses on measuring interfacial chemical properties. It can be used to analyze interfacial chemical characterizations like surface tension and its contributions (dispersive force, polar force), interface tension, surface free energy of solid and its contributions (dispersive force, polar force, hydrogen bond force, Lewis acid & base and more), interface rheology, interfacial viscosity, adhesive work, wetting line, wetting behavior via analysis of drop shape or lamella profile of drop / bubble that shaped on interface of liquid-gas, liquid-liquid, liquid-solid or liquid-liquid-solid. It also can be used to characterize / analyze / predict / describe various vital physical chemical properties, such as spreading, wettability, adhesion, absorption, competition, sedimentation, penetration, biocompatibility, foaming, solubilization and surface heterogeneity, as well as research of new material (super hydrophobic / hydrophilic material simulation), QC (analysis of surface cleanness).

C60 is drop shape analysis based system which focuses on measuring interfacial chemical properties. It can be used to analyze interfacial chemical characterizations like surface tension and its contributions (dispersive force, polar force), interface tension, surface free energy of solid and its contributions (dispersive force, polar force, hydrogen bond force, Lewis acid & base and more), interface rheology, interfacial viscosity, adhesive work, wetting line, wetting behavior via analysis of drop shape or lamella profile of drop / bubble that shaped on interface of liquid-gas, liquid-liquid, liquid-solid or liquid-liquid-solid. It also can be used to characterize / analyze / predict / describe various vital physical chemical properties, such as spreading, wettability, adhesion, absorption, competition, sedimentation, penetration, biocompatibility, foaming, solubilization and surface heterogeneity, as well as research of new material (super hydrophobic / hydrophilic material simulation), QC (analysis of surface cleanness).  Optimized Mechanics and Control System: More Professional, Stable, More Accurate, and Easier to Control

Optimized Mechanics and Control System: More Professional, Stable, More Accurate, and Easier to Control Optical Vision System-Clearer, Higher Speed and More Professional

Optical Vision System-Clearer, Higher Speed and More Professional  Dosing System of Higher Accuracy and More Convenient to Control

Dosing System of Higher Accuracy and More Convenient to Control World Leading, More Powerful, Automatic and Ergonomic Analytical Software- CAST®3.0

World Leading, More Powerful, Automatic and Ergonomic Analytical Software- CAST®3.0 Various and Fully Functional Software Modules for Drop Shape Based Interface Chemistry Analysis

Various and Fully Functional Software Modules for Drop Shape Based Interface Chemistry Analysis  Specifications

Specifications C601 | C602 | |||||

Appearance | ||||||

Subject | Standard image analytical system | Professional image analytical system | ||||

Hardware Specifications | Sample Stage control | X-Axis | Manual, travel:100mm, accuracy 0.01mm; Max. travel 300mm for option | Automatic, travel:100mm, accuracy 0.01mm; Max. travel 300mm for option | ||

Y-Axis | ||||||

Z-Axis | Manual, travel: 50mm; accuracy: 0.01mm | |||||

Rotation | manual Integral rotary mechanism in which lens rotates with sample stage for advancing /receding/ roll-off contact angle measurement | automatic Integral rotary mechanism in which lens rotates with sample stage for advancing/receding/roll-off contact angle measurement | ||||

Optional with rotated stage with internal rotation | ||||||

Level Adjustment | Level adjustment of sample stage used manual fine tuning knob, whole instrument level adjustment and camera lens tilting unit | |||||

Sample Stage Size | 100*100mm | 100*100mm | ||||

Max Sample Size | 300(W)*∞(L)*100(H)mm | 300(W)*∞(L)*100(H)mm | ||||

Other control | Dosing Control | X,Y-Axis movable, travel: 12.5mm; accuracy: 0.01mm for adjusting the droplet position and focal distance | ||||

Dosing Control(Z) | Automatic, travel: 12.5 mm, accuracy 0.01mm; For drop transferring | |||||

Tilting of Camera lens | One-dimensional tilting unit with micrometer and locking function | |||||

Dosing System | Types | Automatic direct syringe pump | ||||

Accuracy | 0.001mm 2nL(0.002uL) | |||||

Drop Transferring | Automatically –controlled | |||||

Needle | Disposable needles, including 0.24, 0.3, 0.5, 0.9,2mm OD stainless steel needles, 0.2 OD needles as well as PTFE needles, etc., especially for measuring contact angles of super-hydrophobic materials or contact angles between glue and solid materials. | |||||

Optical Vision System | Lens | 6-fold zoom telecentric lens ( 0.37-4.5-fold magnification);distortion rate(Optical distortion):0.01%;field of vision(FOV):0.80*1.07-10.14*13.52;NA : 0.03-0.085(4.5X); | ||||

Camera | Industrial mono video camera, USB 2.0 port, Resolution: 752*480 (standard WVGA format); Image speed: -87(Full Screen)-600(752*60) FPS,FOV:1.33-17.14mm; UV optical filter Cameras with higher resolutions of 130M,300M,500M are available | |||||

Background Light System | Illumination-adjustable monochromatic LED cold parallel background light with clearer image shape of drop shape | |||||

Software | SM01:Contact Angle Measurement Module(ADSA-SD) | 5 kinds of drop shape states: | Pendant Drop, Sessile Drop (liquid/gas, liquid/liquid/gas), Captive Drop, Tilted Plate, and Oscillating Drop. | |||

7 methods to calculate contact angles: | θ/2 (WH), circle fitting , ellipse fitting , RealDrop™ , curve ruler (tangent fitting ), Spline curve-fitting , and Young-Laplace equation fitting (ADSA™), etc. | |||||

Data acquisition: Combination of both full-automatic measurement and manual modification. Just press “Measure”, the software will complete the whole process of capture, finding edge, finding sensitive spots, fitting curves, calculating contact angle values, and displaying calculation results without manual participation so as to reduce the effect of human factors. | ||||||

Contact angle measuring technology: mathematical model fitting and real-drop contour measurement solves the problem of measurement of asymmetric drop shape or drop without apex. | ||||||

Automatic curve base line correction: Correction of upper convex sample surface, lower concave surface, or roughness of surface. | ||||||

Auto detection of base line | ||||||

Measurement of static/dynamic contact angle includes measurement of advancing/receding contact angle/tilt angle/roll off angle/equilibrium contact angle/thermodynamics intrinsic contact angle | ||||||

Unique dual-software triggering technology: Measurement of first-time-point contact angle for analyzing powder, paper and other hygroscopic materials; whole-process capture of small contact angle measurement. | ||||||

Calculation and comparison of left and right contact angle and their average values. | ||||||

Automatically generated data graph: Real-time observation of contact angle changes. | ||||||

Powerful database management: one-to-one correspondence of data and drop images; backup, compression, and exporting to Excel files; measured values and curve-fitting results can all be saved into exported image, visually and clearly. | ||||||

|

Video recording: recording live images in AVI format and also for PPT file.

| ||||||

Automatic calculation of droplet volume, adhesive work and Equation of State based surface free energy for measurement of surface tension of films, to replace Dyne test pens. | ||||||

SM02 Measurement of Surface/Interface Tension by Pendant Drop(ADSA-PD) | Analysis of surface tension on liquid-gas/liquid-liquid by RealDrop™ based Young-Laplace equation | |||||

Young - Laplace equation fitting method based ADSA module for measurement of surface/interface tension | ||||||

Fitting methods: Bashford-Adams(BA)table and Realdrop | ||||||

Auto measurement of time dependence interface tension with pendant drop method | ||||||

SM03 Analysis of Surface Free Energy and Wettability(SFE&WBA ) | 12 evaluation models for surface free energy Exclusively providing 12 methods for calculating surface free energy, e.g. Equation of State (Neumann et al.), Good-Girifalco, Owen-Wendt-Rabel, Simple Fowkes, Extended Fowkes, WU method 1-2, Schultz method 1-2, Acid-base (Van OSS & Good), Jhu, and Zizman Plot (critical surface tension) method, for measurement of surface free energy and its distribution (dispersive force, polar force and hydrogen bond value, and Lewis acid-base, etc.) of low/high free energy solid. | |||||

Wetting Behavior Analysis / wetting envelopes | ||||||

300 kinds of liquid with 800 data | ||||||

General Specifications | Measuring Range of Contact Angles | 0°<θ<180° | ||||

Resolution | 0.01° | |||||

Accuracy | ±1 (θ/2 method) ±0.1° circle fitting method | |||||

Measuring Range of Interface Tension | 0.001-2000mN/m | |||||

Measuring Resolution of Interface Tension | 0.001mN/m | |||||

Measuring Methods of Interface Tension | Bashford-Adams(BA)table(select plane),Young-Laplace fitting (4th generation) | |||||

Dimension and Weight | 350Wx800Lx600Hmm 35kg | |||||

Power Supply | AC100~240V 50/60HZ | |||||

Related Keywords