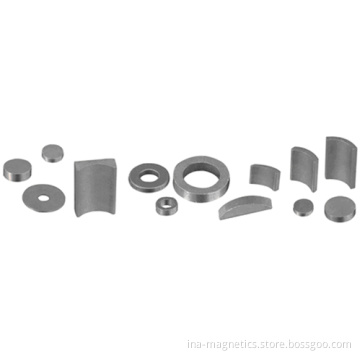

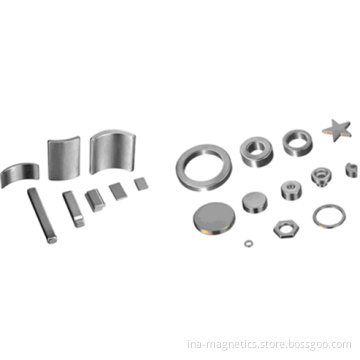

All Kinds of Sintered SmCo Magnet (Sm2Co17)

- Payment Type:

- L/C, T/T, Paypal

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Shenzhen, Guangdong, China |

|---|---|

| Payment Type: | L/C, T/T, Paypal |

Product Description

Product Description

Sintered SmCo Magnets

Summarize:

The SmCo permanent magnet have two types available: 1: 5 type(SmCo5)&2: 17 type(Sm2Co17);

Sintered Samarium Cobalt magnets are inherently very brittle, conventional machining techniques cannot be processed. If machining is required, high concentration diamond grinding wheels must be used, and wateroil coolant is necessary.

Property:

The SmCo magnets Curie temperature is between 710 and 880 C, the maximum operation temperature between 250 and 350C. It is higher than the NdFeB materials which maximum operation temperatures is 230C;

The SmCo materials has better corrosion resistance than NdFeB materials;

The SmCo material have the lower magnetic flux loss than the NdFeB materials when operation temperature above about 150C;

SmCo5 magnet have (BH)max of about 18 MGOe (140 kJ/m3), has a reversible temperature coefficient of -0.05%/C.;

Sm2Co17 magnet have (BH)max of 30 MGOe (240 kJ/m3), machinning processing of Sm2Co17 is very difficult, has the advantage of containing less Cobalt than SmCo5. Raw material costs are lower;

Sm2Co17 is also more corrosion resistant and more stable at very high temperatures. It has the best reversible temperature coefficient of all rare earth alloys, typically being -0.03%/C.

Application field:

The SmCo permanent magnet Principle applications are servo-motors, pump couplings, and sensors; The SmCo permanent magnet particular application is in high-temperature, high-humidity and corrosive environment.

Summarize:

The SmCo permanent magnet have two types available: 1: 5 type(SmCo5)&2: 17 type(Sm2Co17);

Sintered Samarium Cobalt magnets are inherently very brittle, conventional machining techniques cannot be processed. If machining is required, high concentration diamond grinding wheels must be used, and wateroil coolant is necessary.

Property:

The SmCo magnets Curie temperature is between 710 and 880 C, the maximum operation temperature between 250 and 350C. It is higher than the NdFeB materials which maximum operation temperatures is 230C;

The SmCo materials has better corrosion resistance than NdFeB materials;

The SmCo material have the lower magnetic flux loss than the NdFeB materials when operation temperature above about 150C;

SmCo5 magnet have (BH)max of about 18 MGOe (140 kJ/m3), has a reversible temperature coefficient of -0.05%/C.;

Sm2Co17 magnet have (BH)max of 30 MGOe (240 kJ/m3), machinning processing of Sm2Co17 is very difficult, has the advantage of containing less Cobalt than SmCo5. Raw material costs are lower;

Sm2Co17 is also more corrosion resistant and more stable at very high temperatures. It has the best reversible temperature coefficient of all rare earth alloys, typically being -0.03%/C.

Application field:

The SmCo permanent magnet Principle applications are servo-motors, pump couplings, and sensors; The SmCo permanent magnet particular application is in high-temperature, high-humidity and corrosive environment.

Related Keywords

Related Keywords