Machine Part for Submarine

- Payment Type:

- L/C, T/T, Paypal, Western Union

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Shenzhen, China |

|---|---|

| Payment Type: | L/C, T/T, Paypal, Western Union |

Product Description

Product Description

Machine Part For Submarine(GS-109)

1. Description

Gensun Precision Machining can produce diffrent CNC machined components and CNC machining parts according to customer's CAD and 3D drawings.

1. We supply: CNC machining, CNC Machining Parts, CNC Lathe Parts, CNC Machined Part, Turning parts, Milling parts, Non-standard CNC part , Precision Machining part in China.

2. Material: Aluminum Alloys, Copper, Brass and Bronze Alloys, Stainless, Carbon and Tool Steels, Plastics, Specialty Alloy (i.e. Titanium, Kovar, Inconel, MoCu, WCu).

4. Precision Machining Parts, Turning parts, CNC machined Housing, Machined Parts, Lathing Parts, Machinery Parts, EDM Components, CNC Milling Accessories, Hardware Fittings, Metal Forming Parts, CNC Turned Shaft, Aluminum Alloys parts, Automotive parts, CNC Grinding Components, Customized Screw, etc.

5. Machining Available: CNC Turning, CNC Milling, Machine Center, Turning, Millings, Drilling, Tapping, Grinding, Slotting, Spark-erosion machining.

6. Heat treatments available: Annealing, Normalizing, Tempering, Nitriding, Induction Hardening.

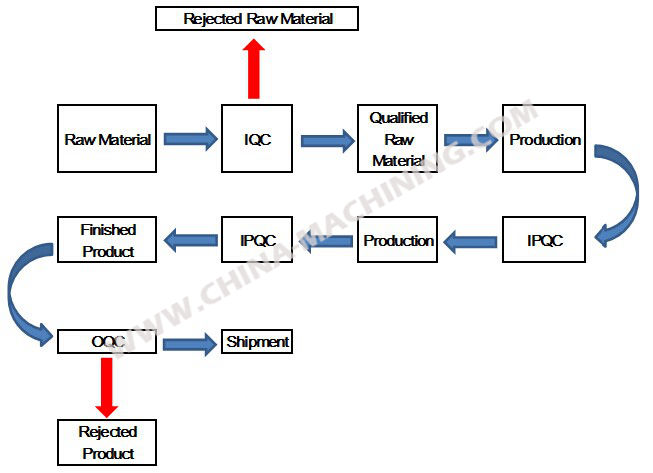

2. Quality Control

Material Supply

To be sure material specification and size correct.

To be sure material chemical composition correct, material certification must be provided in each material purchasing lot.

Equipment Maintain

Machining equipments maintain: Checked by each day, have records to track.

Inspection equipment maintain: Checked by each 15 days, have records to track.

Machining Process

Setup work instruction chart for each part.

Check production process and updated drawing issue before machining.

Fixed Inspection: 4 times/shift, have records to check, carried by QC.

Random Inspection: to avoid uncertain potential quality issues.

Final Inspection: Each part have its final inspection stardard before packing, have inspection sheet to track.

Packing and Assembly

To meet custom requirements, including labels, cartons, pallets etc before shipment.

Quality Control Process

Inspection Equipment

1. Description

Gensun Precision Machining can produce diffrent CNC machined components and CNC machining parts according to customer's CAD and 3D drawings.

1. We supply: CNC machining, CNC Machining Parts, CNC Lathe Parts, CNC Machined Part, Turning parts, Milling parts, Non-standard CNC part , Precision Machining part in China.

2. Material: Aluminum Alloys, Copper, Brass and Bronze Alloys, Stainless, Carbon and Tool Steels, Plastics, Specialty Alloy (i.e. Titanium, Kovar, Inconel, MoCu, WCu).

4. Precision Machining Parts, Turning parts, CNC machined Housing, Machined Parts, Lathing Parts, Machinery Parts, EDM Components, CNC Milling Accessories, Hardware Fittings, Metal Forming Parts, CNC Turned Shaft, Aluminum Alloys parts, Automotive parts, CNC Grinding Components, Customized Screw, etc.

5. Machining Available: CNC Turning, CNC Milling, Machine Center, Turning, Millings, Drilling, Tapping, Grinding, Slotting, Spark-erosion machining.

6. Heat treatments available: Annealing, Normalizing, Tempering, Nitriding, Induction Hardening.

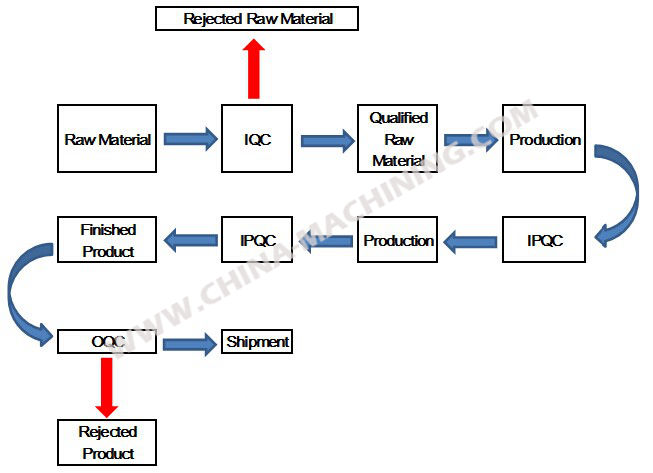

2. Quality Control

Material Supply

To be sure material specification and size correct.

To be sure material chemical composition correct, material certification must be provided in each material purchasing lot.

Equipment Maintain

Machining equipments maintain: Checked by each day, have records to track.

Inspection equipment maintain: Checked by each 15 days, have records to track.

Machining Process

Setup work instruction chart for each part.

Check production process and updated drawing issue before machining.

Fixed Inspection: 4 times/shift, have records to check, carried by QC.

Random Inspection: to avoid uncertain potential quality issues.

Final Inspection: Each part have its final inspection stardard before packing, have inspection sheet to track.

Packing and Assembly

To meet custom requirements, including labels, cartons, pallets etc before shipment.

Quality Control Process

Inspection Equipment

| 3. Product Info | |

| Product Name | Machine Part For Submarine(GS-109) |

| Model No. | GS-109 |

| Material | Brass |

| Process | CNC machining |

| Finish | |

| Key Tolerance | ±0.001 |

| Application | Submarine |

| 4. Professional Spectrum | |

| Material Available | Aluminum, Carbon steel, Stainless steel, Spring steel, Mild Steel, Bronze, Brass, Copper alloy, Plastic, POM,Titanium, Kovar, Inconel, MoCu, WCu, etc |

| Surface Treatment Available | Zinc/Nickel/Chrome Plating(color or natural), Silver Plating, Gold Plating, Galvanization, Anodizing, Hard Anodizing, Oil Spraying, Powder Coating, Polishing, Passivate, Brush, Wire drawing, Sand blasting, etc. |

| Manufacturing Methods | CNC Machining, Milling, Turning, Drilling, Grinding, Wire Cutting, EDM, Die Casting, Stamping, Bending. |

| Specification | OEM & make per customer' s drawing or sample. |

Related Keywords

Related Keywords