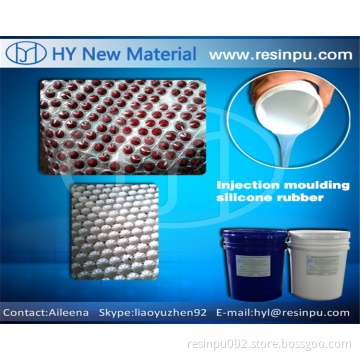

Injection Molding Silicone Rubber for Jewelry

- Payment Type:

- T/T, L/C, Western Union, paypal

- Incoterm:

- FOB

- Min. Order:

- 100 Kilogram

- Min. Order:

- 100 Kilogram

- Delivery Time:

- 5 Days

- Transportation:

- Ocean, Air

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong china |

|---|---|

| Productivity: | 20000KG |

| Supply Ability: | 100000KG |

| Payment Type: | T/T,L/C,Western Union,paypal |

| Incoterm: | FOB |

| Certificate: | ISO 9000/9001/9004/19011: 2000 Others |

| Transportation: | Ocean,Air |

Injection Molding Silicone Rubber for Jewelry

Please don't hesitate to contact us if you have any interest on our products

1.Silicone mold injection characteristics

• Addition silicone rubber , mix ration 10:1

·can be cued even with large molds

High temperature resistance ,can reach to 300-500C ,

Food Grade with FDA certificate

High tear strength and tensile strength ,and large reproduction times

Heat Temperature cured , Easy operated

2.Usage of the Injection silicoen rubber

Applied for the molds making for Jewelry , such as zircon imitation, imitation precious stones, resin diamond, crystal facets drilling, drilling and drilling simulation class mold making, can be used for silicone products making (such as sex toys ) ,precision auto, models, mechanical parts and other products manufacturing model can also be used in the furniture industry and the electronics industry mold the production of manufactured products, high transparency, good mold release advantages can be seen filling the mold material is cast defects such as bubbles

3.TDS of the Injection Silicone

|

Code |

MJ2120A/B |

|

Appearance |

Transparent liquid |

|

Mix ratio |

10:1 |

|

Viscosity (CPS) |

70000 |

|

Pot life(25℃) min |

30 |

|

Cure time(80℃/h) |

0.5h~1h |

|

density/ g·cm-3 |

1.1 |

|

hardness(shore A) |

20 |

|

Enlogation/% |

≥450 |

|

Tear strength/ KN·m-1 |

≥15 |

|

Tensile strength/Mpa |

≥5.6 |

|

shrinkage/% |

0.1 |

4.Operation ways of Injection Molding

a.Mixed: A component (based glue) and Part B (curing agent) ratio of 10:1 by weight, mixed, mixed either manually or using equipment.

b.Vacummping : mixed silicone A and B , When used in small amounts can be in a vacuum desiccator under vacuum, the volume will foamed plastic material can be increased 4-5 times, so degassing vessel volume should be less than bulky plastic material 4 to 5 times, after a few minutes gel volume returns to normal, no air bubbles escaping when the surface (about 10 minutes) to complete the degassing step.

c.Clean your Original mold (sex toys molds ) ,pls note that , the molds won`t be contact with condensation silicone rubber before , and not contains chemical element such as N.S.P, otherwise the silicone won`t be cured .

d.Pour the silicone rubber into your sex toys molds .

e. cured the silicone rubber at 80C to 120C , then the silicone will be cured ,and then demould.

5.Packages

a,20kgs or 200kgs per drum , and keep in a cold ,windly place

b,Shelf Life 6-8 months under the room temperature .

6.Payment & Shipping Terms

CFR, CIF, FOB

We Promise

cost price for the first cooperation

Our Advantages

a.We are the manufacturer, not only trading company, price will be much competitive

b.We have produced strickly in according to the customers` request.

c. Our operational theme of [good Quality , high Credibility&best service".

d. Free samples before placing orders;

e.Factory visit could be arranged at any times.

For more information of Injection Molding Silicone Rubber for Jewelry, pls feel free to contact Aileena

Contact:

hyl(at)resinpu(dot)com

Related Keywords