Spring Pin Reinforced type HSS Punches TiCN Coating Heavy L

- Min. Order:

- 1

- Min. Order:

- 1

- Delivery Time:

- 30 Days

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China (mainland) |

|---|

Spring Pin Reinforced type HSS Punches TiCN Coating Heavy Load for plastic mold

Surface Coating Provide :

1. TiN - ( Titanium Nitride ) PVD Coating

Alteration Order Code : TIN -- Add 3 days to Delivery

TiN is the least expensive and most commonly used PVD ( Physical vapor deposition ) wear resistant

coating offering :

- Excellent wear resistance on cutting edges and wear surfaces

- Excellent lubricity

- Suitable thermal stability for most cold work metalworking applications

- High microhardness of 2300 Vickers

Note : TiN works best when used with lubricants and is not recommended for uses in stainless

steel,nickel ,or copper applications

2. TiCN - ( Titanium Carbon Nitride) PVD Coating

Alteration Order Code : TCN-- Add 4 days to Delivery

TiCN has the broadest range of application use regarding PVD coating including stainless steel ,nickel ,and

copper metal working operations offering :

- Higher hardness and lower coefficient of friction and thay of TiN coating ,resulting in extremely

high wear resistance on cutting edges and wear sufaces

- Improved lubricity Extremely high micro hardness of 3000 Vickers

Note: Suitable for uses in stainless steel ,nickel ,or copper applications

3. TiAIN - ( Titanium Aluminum Nitride ) PVD Coating

Alteration Order Code : TAN-- Add 3 days to Delivery

TiAN is idea for application where suface heat generated ,which converts the aluminum constituent to

aluminum oxide for added protection against shear stress and wear resistance on cutting edges .

- High thermal stability

- Extremely high micro hardness of 3400 Vickers

1. Material

SKD11 /SKH51 / Power HSS / A2 / M2 / D2 / Carbide / ASP23 / Vanadis4

2. Hardness

58 to 62HRC or depends on processing materials

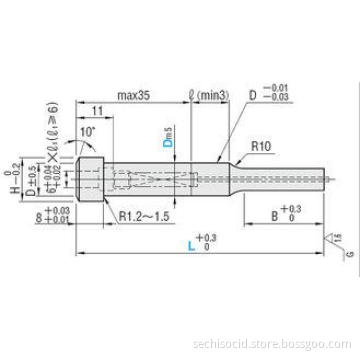

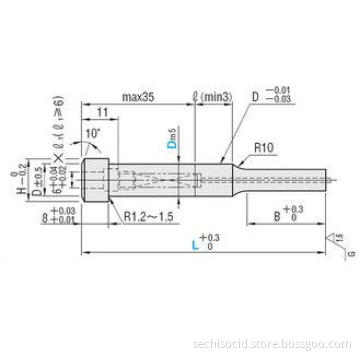

3. Specification

- Standards: Dayton / Lane / DIN / ISO / Fibro / Moeller / HASCO

- Tolarance : g5

- Further dimensions, lengths and materials available on request

- Customized sizes are accepted

- Shapes: oblong, square and hexagon

- Coating service TiN, TiCN and Aitain

- Service: made-to-order and standard with stock

- Good-quality and precision

- High precison ,finishing machining

- Working speed: 180 to 220/min

- Polishing: can make close to Ra 0.4 standard is R 0.8

4. Machinery & Equipments

- CNC machining center; CNC lathe; Normal lathe; CNC milling machine;

- General punching machine, CNC turning center; Wire EDM, etc.

- And we also can offer 4 or 5 axis-CNC center processes.

- General milling machine; General drilling machine; General planning and grinding machine

Applications:

- Punching Mold

- Automobile Die

- Suitable for different type of plastic bag making machine

- Can punching for 0.01mm single-layer material of plastic bag,paper, non-woven fabrics. PE, OPP, PO, PP, PVC, PPE, PPU, OPE film

Further Information

|

Testing |

Digital Height Gauge, caliper, Coordinate measuring machine, projection machine, |

|

QC |

1) Technicians self-check in production |

|

Main Markets |

North America, South America, Eastern Europe , West Europe , North Europe, |

Packing & Delivery

|

|

Package |

Coated with anticorrosive oil, packed in carton box |

|

Express |

DHL, FedEx, UPS, TNT,by Sea . |

Main products

- HSS punch ,Precision punch ,Ejector punch ,Punch ejector pins, Ball-lock punches, Punch retaine

- Die button

- Guide pillars ,Guide bushings ,Guide post set ,Ball cages

- Mold ejector pins ,Ejector sleeves

- Oiless bush , Bronze Wear Plate

Spot Light of CIVADA

· Factory opened more than 12 years

· Factory Size : 1,000-3,000 square meters

· Reserch & Development Group : 8 people

· Equipment & Machine : all imported precision ones

· Good reputation in Mold Components Area.

· One-step servise for your much time and cost .

· Complete quality management system .