Straight injection molding ejector pins oxidated for automo

- Min. Order:

- 1

- Min. Order:

- 1

- Delivery Time:

- 30 Days

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China (mainland) |

|---|

Straight injection molding ejector pins oxidated for automotive dies

1. Material

- SKH 51-- JIS High Speed Steel ( M2 )( 1.3343 ) equivalent

- SKD 61-- JIS Die Steel ( H13 )( BH13 )( STD61 ) ( 1.2344 ) equivalen

- 65 Mn , SUJ2 , HSS , etc

2. Hardness

- 58 to 62 HRC or depends on processing materials

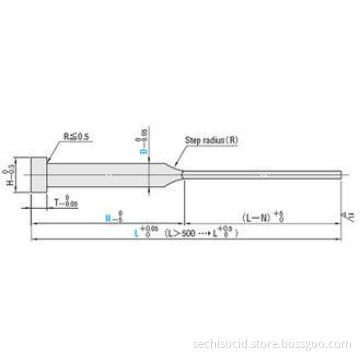

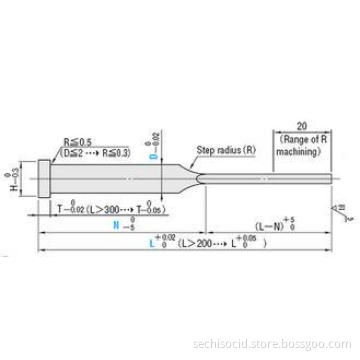

3. Specifications

- Standards : MISIMI / DIN / AISI etc.

- Mounting method flange fixing

- Further dimensions, lengths and materials available on request

- Customized sizes are accepted

- Service: OEM available , and standard with stock

- Closest tolerance : shaft 0 ~ - 0.01 mm , head 0 ~ - 0.05 mm

- Polishing: can make close to Ra 0.4 standard is R0.8

- Good-quality and precision

- Nitrogen treatment to improve the hardness

- More products can be produced according to DANLY / DME / HASCO / TOHATSU / FIBRO / AGATHON / STRACK / PEDROTTI / RAYMOND / FUTABA / SANKYO / PROGRESSIVE / RABOURDIN , etc.

Application

- Plastic injection mold components

- Ejector pins are used to eject completed parts from die moulds and are commonly used in

the plastics, automotive, aeromotive and medical industries, amongst others. A blade shape is used when

there is only a small surface area on the finished part. They are also known as knockout pins, knock-out

pins or KO pins. When the mould is opened, the pins extend into the mould cavity, push the part out, and

then retract, allowing the mould to close and be refilled.

- Important factors to consider when selecting ejector pins are corrosion resistance,

durability, tolerance and tensile strength. Ejector pins can be made with a variety of treatments, which

affect the hardness of the pin. By choosing the right ejector pin for the application, the lifespan and

durability of the pin will be enhanced.

- Through hardened pins are good all-purpose steel pins that are heat-treated to be uniformly

hard throughout their diameter. They are often used for injection moulding of plastics and can be used in

cooler moulding environments below 200°C.

- Case hardened pins are nitrided pins that are suitable for die casting and can be drilled or

tapped. They can be used at temperatures above 200°C and are quite durable. They can chip when

compared to through hardened pins but have a greater life expectancy at higher temperatures.

- Blackened or oxidated ejector pins are designed for extremely high temperature working

environments. They can be used at temperatures from about 600-1000°C. These ejector pins have a self

lubricating surface coating that allows them to be used at these high temperatures.

- Ejector pins can be further enhanced by our TiN TiCN HW coating and other coatings which

protect them and make them more durable. These coatings work by reducing friction so that the pins

become more wear resistant and the ejection of the part becomes more consistent.

- Ejector sleeves are hollow and can be used to protect and guide the pin, further enhancing

its lifespan.

Machinery & Equipments

- CNC machining center; CNC lathe; Normal lathe; CNC milling machine;

- General punching machine, CNC turning center; Wire EDM, etc.

- And we also can offer 4 or 5 axis-CNC center processes.

- General milling machine; General drilling machine; General planning and grinding machine

Further Information

|

Testing |

Digital Height Gauge, caliper, Coordinate measuring machine, projection machine, |

|

QC |

1) Technicians self-check in production |

|

Main Markets |

North America, South America, Eastern Europe , West Europe , North Europe, |

Packing & Delivery

|

|

Package |

Coated with anticorrosive oil, packed in carton box |

|

Express |

DHL, FedEx, UPS, TNT,by Sea . |

Main products

- HSS punch ,Precision punch ,Ejector punch ,Punch ejector pins, Ball-lock punches, Punch retaine

- Die button

- Guide pillars ,Guide bushings ,Guide post set ,Ball cages

- Mold ejector pins ,Ejector sleeves

- Oiless bush , Bronze Wear Plate

Spot Light of CIVADA

- Factory opened more than 12 years

- Factory Size : 1,000-3,000 square meter

- Reserch & Development Group : 8 people

- Equipment & Machine : all imported precision ones

- Good reputation in Mold Components Area.

- One-step servise for your much time and cost

- Complete quality management system .