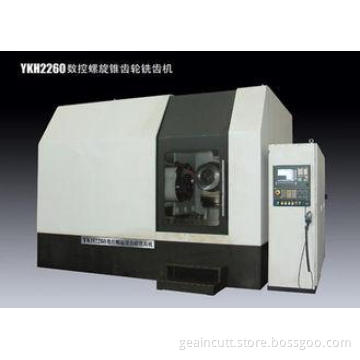

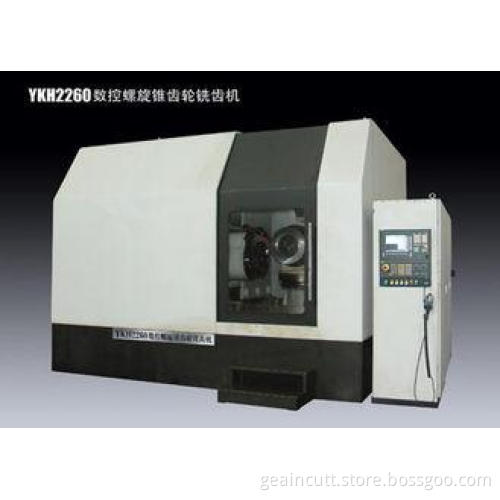

Large CNC Spiral Bevel Gear Milling Machine With Germany Si

- Min. Order:

- 1

- Min. Order:

- 1

- Delivery Time:

- 30 Days

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|

Large CNC Spiral Bevel Gear Milling Machine With Germany Siemens Control System

Quick Detail:

This machine is used for processing a maximum diameter of 600 mm, CNC spiral bevel gear milling machine maximum modulus of 12 mm.

This machine is CNC milling machine has the function of six axis five linkage machine tool structure, high rigidity and improve the adjustment package, both for the wet cutting with the traditional cutter, can also be used for dry cutting by the blade structure of cutter, the realization of green processing and efficient production.

This machine can be used for intermittent indexing method end milling arc contraction bevel gear and hypoid gear (Gleason), can also be used for continuous indexing milling machining cycloid high bevel gear and hypoid gear (OERLIKON), the machining precision can reach the level of 6 (GB/T11365-89).

This machine is especially suitable for automobile, engineering machinery, military industry and other industries small batch trial production and mass production.

Description:

1.This machine consists of bed, column, cutting tool, workpiece headstock headstock, turret mechanism, reasonable layout, good integral rigidity.

2.The machine adopts Germany Siemens (SIEMENS) control of 840D numerical control system and digital servo system, the realization of the six axis five linkage. The three linear axes (X, Y, Z), the feedback control of closed loop position, three rotation axes (A, B, C) A, C axis adopts gear drive spindle motor gap eliminating structure, B axis adopts torque motor direct drive. Therefore, the six shaft ensures the transmission quality of high precision.

3.This machine three linear axes feed motion are used in high precision ball screw, ensure the high quality feed accuracy.

4.The machine tool workpiece headstock swinging by the turntable, the turntable (B axis) is directly driven by a built-in torque motor, high precision, high rigid motion.

5.The machine tool spindle box column and the straight line guide rail, hanging plate structure.

6.This machine is based on tooth creation application adjustment principle of software, can achieve optimal contact, calculation of transmission quality of motion control and tool parameters, calculation card management software through the man-machine interface and adjustment of friendly, input, modification of machine tools and tool parameters.

7.The structure of the machine tool and chip, which can "wet" and "dry cutting of processing mode".

8.This machine is applicable to configure security, protective cover and electric cabinet air conditioner.

|

workpiece Dimension |

||||

|

Maximum module |

mm |

12 |

||

|

The maximum pitch cone length |

mm |

350 |

||

|

Maximum machining diameter of the pitch circle |

mm |

600 |

||

|

Root cone angle |

|

Maximum 84º0′ |

||

|

Minimum 5º30′ |

||||

|

extreme ratio |

mm |

10:1 |

||

|

The maximum helix angle |

|

45º |

||

|

Maximum Cutting Depth |

mm |

25 |

||

|

Maximum face width |

mm |

100 |

||

|

Number of teeth |

|

5~200 |

||

|

The main parameters of the workpiece spindle |

||||

|

Spindle taper big end diameter |

mm |

203.2 |

||

|

taper |

mm |

1:20 |

||

|

Cone Length |

mm |

180 |

||

|

Diameter of through hole |

mm |

188 |

||

|

Spindle flange diameter |

mm |

220 |

||

|

Cutter diameter |

6,7.5,9,12,18 |

|||

|

speed of gyro axis |

|

|

||

|

A axis |

rpm |

25~250 |

||

|

B axis |

rpm |

0~10 |

||

|

C axis |

rpm |

30~350 |

||

|

other |

||||

|

total power of motors |

KVA |

85 |

||

|

overall dimension (L×W×H) |

mm |

4500×3500×3500 |

||

|

net weight |

t |

25 |

||

Specifications:

|

Place of Origin: |

China |

|

Brand name |

JJR |

|

Certification: |

ISO9000 |

|

Model Number: |

YKH2260 |

|

Minimum Order Quantity: |

1set |

|

Price: |

negotiation |

|

Packaging Details: |

wooden case |

|

Delivery Time: |

1month |

|

Payment Terms: |

T-T L/C |

|

Supply Ability: |

50set/month |

Company Profile:

Heng Yong company gathered many experienced experts. This team is lead by people have over decades of experience, and filled with young, energetic engineers. With strong research and developing ability, our company put extraordinary effort on developing complete sets of gear machinery. Now we are able to provide our customer the main products as follows: Gear Shapers, Straight Bevel Gear Generators, Spiral Bevel Gear Generators, Spiral Bevel Gear Grinders, Hypoid Gear Testers, Gear Lappers, Gear Quenching Press, Gear Chamfering Machines, Gear Hobbers, Honing Machines, Vertical & Horizontal Machining Centers, Special Precision Speed Reducers, Roll Stander for Seamless Tube Stretch Reducing Mill, Gear Coupling Family, Low Drive Devices and Environmental Protective Equipment of 16 kinds, more than 30 families, and more than 150 types and specifications. The company focus on developing heavy-duty, large CNC gear machinery, which are urgently needed by the government and makes industrialize as soon as possible, provide a great variety of advanced gear machinery to the market. The company is using the leading 3D designing software for developing and designing. The company combines producing with research and development by Cooperating with TIANJIN University and other colleges for many years.