Medical Appliances Plastic Injection Mold Making / Custom P

- Min. Order:

- 1

- Min. Order:

- 1

- Delivery Time:

- 30 Days

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | GuangDong China( Mainland) |

|---|

1. Hot Runner Medical Equipment Parts Plastic Injection Mould

YongHeTai is specialized in desiging and manufactring

1. plastic injection mould / plastic injection moulding / plastic mould / plastic moulding / injection moulding

/ plastic mould injection

2. manufactory of mould and plastic injection products

3. Single and Multi-cavity

4. OEM and ODM are welcomed

5. Strict quality control

2.Mould Service Processing

|

1.Enquiry |

Our customers send 2D drawing, 3D or samples of products to us. |

|

↓ |

|

|

2. Quotation |

According to the information customers sent ,we make an offer with mould feature(material,size,life,price ect.),incoterms,payment,delivery time ect. |

|

↓ |

|

|

3. Negotiation |

All issues about mould,including mould feature,,payment and so on. |

|

↓ |

|

|

4.Place an order |

Sign Contract |

|

↓ |

|

|

5.Mould Design |

According to customers 3D or samples and requests to design the mould,before mould processing ,we will send mould design to customer to confirm it

|

|

↓ |

|

|

6.Mould Test |

We send the test sample to customer until meet customers requests. |

|

↓ |

|

|

8.Delivery |

Delivery by sea or according to customers. |

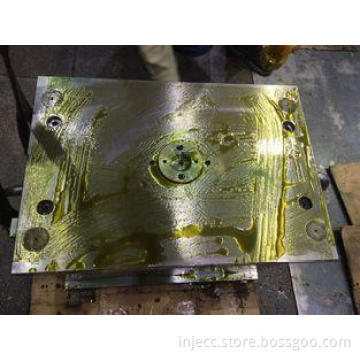

3.Main Machine For Making Plastic Injection Mould

4.How to pack the mould

1.Check mould component

2.Cleaning mould cavity/core and spread slushing oil on the mould

3.Cleaning mould surface and spread slushing oil on the mould surface

4.Put into the wooden case

5.How To Shipping

Shipping By Sea Or By Air

6.Contact Information

IF you have any projets or enquiry in hand. PLEASE contact us.

Choose ShenZhen YongHeTai Technology Co., Ltd. Choose high quality and effective-cost!

7.About Us:

Advantages of us:

1.More than 10 Years experience process team and computer ability,software:Auto CAD,Solid-works, Pro/e.OEM/odm

2.We have thousands ready-made moulds,you can get the products you want in best price.

3.Material:aluminum,stainless steel,copper,brass,steel,etc.

4.Production process: die casting,stamping,extrude,turning,milling,drilling,lathing,grinding, wire cutting,etc.

5.Secondary surface operation:zinc/nickel/ chrome plated,Trivalent Chromate/Alodize/Surtec,anodize,

powder coating,

6.Advanced inspection measure by CMM,gauges,roughness tester,hardness,tester,etc.

7.Good cost and quality control.

8.Small quantity is acceptable.

Business Scope:

- Products Designing & Manufacturing.

- Rapid Prototyping

- Plastic Moulds Designing & Manufacturing.

- Plastic Injection Molding

- Product Treatment & Product Assembling

- OEM/ODM is welcomed.

Product range:

|

1. Automobile: Air outlet/vent, Rearview mirror, Instrument panel, Horn, Bumper mould, Dashboard mould, etc. |

|

2. Electronic: Wireless receiver part, 3G/4G Modem Wireless Network Cards, USB housing, Mobile phone plastic part, Remote control , Key-press, etc. |

|

3. Mechanical: Junction box, Motor support part, Pump plastic part, Mower, etc. |

|

4. Household: Filter cup, Filter machine, Industrial number calculator part, Juice cup, Plate, Tooling case, etc. |

|

5. Medical: hearing aids, Hollow fiber Dialyzer, Blood-Pressure meter, Stapler, etc. |

|

6. Sports: Golf plastic part, Helmet, |

|

7. Office: Secret code case part, Printer, Duplicator, Atom seal |

|

8. Other Custom Plastic Mould: as your 3D design or sample. |

|

series of products |

auto parts |

|

household appliances |

|

|

bathroom |

|

|

medical appliances |

|

|

construction |

|

|

electrical appliances |

|

|

series of Moulds

|

Plastic injection mould |

|

Silicon rubber mould |

|

|

Die casting mould |

|

|

Stamping mould |

|

|

Blowing mould |

|

|

series of service |

product design |

|

rapid prototype |

|

|

Mould manufacturing |

|

|

product manufacturing |

|

|

finished products assembly |