Professional Plastic Medical Equipment Parts Mould / Moldi

- Min. Order:

- 1

- Min. Order:

- 1

- Delivery Time:

- 30 Days

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | GuangDong China( Mainland) |

|---|

Professional Plastic Medical Equipment Parts Mould / Molding Products with OEM / ODM

1. Household Appliance

YongHeTai is specialized in desiging and manufactring home appliance mould, we supply home appliance mould such as, washing machine mould, electrical fan mould, air condition mould, etc. we have wonderful experience and excellent works before.

2.Mould Service Processing

|

1.Enquiry |

Our customers send 2D drawing, 3D or samples of products to us. |

|

↓ |

|

|

2. Quotation |

According to the information customers sent ,we make an offer with mould feature(material,size,life,price ect.),incoterms,payment,delivery time ect. |

|

↓ |

|

|

3. Negotiation |

All issues about mould,including mould feature,,payment and so on. |

|

↓ |

|

|

4.Place an order |

Sign Contract |

|

↓ |

|

|

5.Mould Design |

According to customers 3D or samples and requests to design the mould,before mould processing ,we will send mould design to customer to confirm it

|

|

↓ |

|

|

6.Mould Test |

We send the test sample to customer until meet customers requests. |

|

↓ |

|

|

8.Delivery |

Delivery by sea or according to customers. |

3.Main Machine For Making Plastic Injection Mould

4.How to pack the mould

1.Check mould component

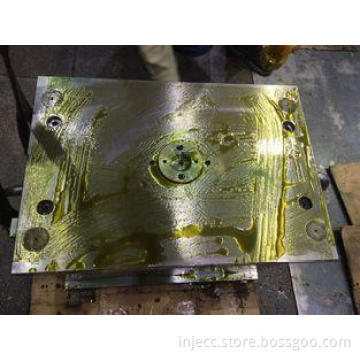

2.Cleaning mould cavity/core and spread slushing oil on the mould

3.Cleaning mould surface and spread slushing oil on the mould surface

4.Put into the wooden case

5.How To Shipping

Shipping By Sea Or By Air

6.Contact Information

7.About Us:

Advantages of us:

1.competitive price for injection mold

2.Quality, reliability and long product life.

3.excellence but simple design.

4.rich experience in the design and manufacturer of plastic injection mould.

5.Customer’s 2D, 3D drawing or samples are welcomed.

6.We will provide you the quotation for Plastic Injection Mould ASAP when we receive your inquiry.

7.you can use your own design or chose our design.

8.if you are not satisfied with the first sample, we will modify the mould until meet your satisfactory.

We will provide the plastic injection mould with the following details:

- Customer design service.

- Prototyping.

- Mold making.

- Manufacturing process control.

- Mold flow analysis service available!

- Reverse mold engineering.

- Customer molding & assembly.

- Cold runner mold and hot runner mold (MoldMaster, Incoe, Masterflow, LKM, Yudo system…etc)

Business Scope:

- Products Designing & Manufacturing.

- Rapid Prototyping

- Plastic Moulds Designing & Manufacturing.

- Plastic Injection Molding

- Product Treatment & Product Assembling

- OEM/ODM is welcomed.

Product range:

|

1. Automobile: Air outlet/vent, Rearview mirror, Instrument panel, Horn, Bumper mould, Dashboard mould, etc. |

|

2. Electronic: Wireless receiver part, 3G/4G Modem Wireless Network Cards, USB housing, Mobile phone plastic part, Remote control , Key-press, etc. |

|

3. Mechanical: Junction box, Motor support part, Pump plastic part, Mower, etc. |

|

4. Household: Filter cup, Filter machine, Industrial number calculator part, Juice cup, Plate, Tooling case, etc. |

|

5. Medical: hearing aids, Hollow fiber Dialyzer, Blood-Pressure meter, Stapler, etc. |

|

6. Sports: Golf plastic part, Helmet, |

|

7. Office: Secret code case part, Printer, Duplicator, Atom seal |

|

8. Other Custom Plastic Mould: as your 3D design or sample. |