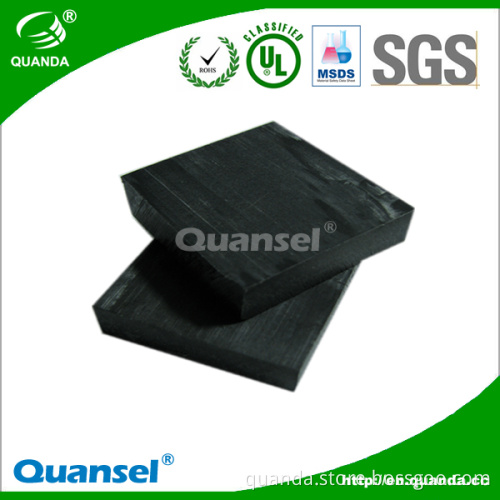

black chemical-resistant Extruded POM Sheet

- Payment Type:

- T/T, L/C, D/P, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 5 Days

- Transportation:

- Ocean, Land, Air

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000MT/M |

| Payment Type: | T/T,L/C,D/P,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS, |

| Transportation: | Ocean,Land,Air |

Specifications

1.Excellent fatigue resistance

2.Good abrasion resistance

3.Self-lubricated and frict

chemical-resistant Extruded POM Sheet

Name: POM (Polyoxymethylene, Polyacetal, Delrin)

Colors Include: Natural (white), Black, other colors

Types: Rods, Sheets, Plates, Tubes, Profiles

Size:

|

POM Sheet |

|

|

Thickness (mm) |

Width/Length (mm) |

|

3--5mm |

700mm x 1200mm |

|

6--12mm |

600mm x 1200mm |

|

15--60mm |

1000mm x 2000mm |

|

65 –150mm |

600mm x 1200mm 1000mm x 1200mm |

Remarks:

---Other sizes, colors can be customized.

---Length, width, diameter and thickness tolerances may vary by manufacturer

---Certain grades available in various colors.

I. POM Description

Good mechanical properties and rigidity, and close to the metal material. It`s an ideal replacement material of copper, cast zinc, steel, aluminum and other metal materials. Excellent fatigue resistance and creep resistance. Good abrasion resistance, self-lubricated and friction. High thermal stability, good chemical stability and excellent electrical insulation. And it can be used in temperatures ranging from -50°C to +110°C.

II. POM Characteristics

Advantages:

♦ High surface hardness, low abrasion consumption, impact fatigue and shock resistance, low coefficient friction, and self-lubricating, therefore, it is the first material choice for manufacturing gear.

♦ High mechanical strength and rigidity. Although the contraction rate is high, the dimension is stable.

♦ Good dielectric properties, solvent resistance, non-stress cracking, no porosity.

♦ Torsional resistance, it can be restored to the original shape when removing the external force.

♦ Low water absorption

Disadvantages:

♦ Poor acid resistance

♦ Weatherability is not excellent especially the UV

♦ Difficult to glue and paint

III. POM Applications

♦ Machinery industry used to produce gears, springs, bearings, wheels, connecting rod, impeller blades etc..

♦ Automobile industry

♦ Electronic and electrical appliances

♦ Others such as toys, windows, water tanks and washing basins

Related Keywords