1070 Pure Aluminium LED Lamp Heat Sink , Cold forging LED C

- Min. Order:

- 1

- Min. Order:

- 1

- Delivery Time:

- 30 Days

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|

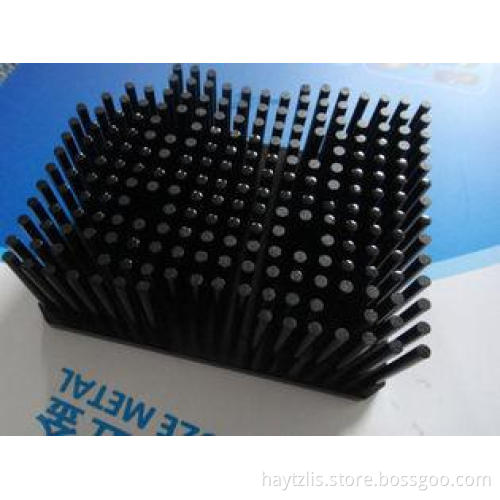

1070 Pure Aluminium LED Lamp Heat Sink , Cold Forging LED Ceiling Lamp Radiator

Description:

* Brand Name: Cold forging LED ceiling lamp radiator

* Material: 1070 pure aluminium

* Size(mm): ø42-75

* Weight(g): 62

* Processing Technic: Cold Forging

* Superficial Treatment: anodised oxidation

* Color: Black/silver/mulitcolour

* Heat Dissipating Capacity: 9W

Applications:

As a Candle lamp radiator

Specifications:

|

Base Diameter |

Ø42mm |

|

Base Thickness |

5mm |

|

Total Hight |

75mm |

|

Diameter of Bore |

Ø33mm |

|

Number of Fins |

36Pcs |

Competitive Advantage:

1, Superior cooling performance

a, The raw material of cold forging heat sinks is 1070 pure aluminium, the thermal conductivity is 226 W/m.K, the thickness of the blades can be made to 0.6mm which increases the heat dissipation superficial area greatly.

b, While, the thermal conductivity is merely 96 W/m.K of the die casting products, its blades can’t be made too more and too thin neither.

c, As to the lathe processing section aluminum heat sinks, the thermal conductivity is merely from 155 to 209 W/m.K, and it must be split-type, the joint will bring huge impacts of the heat conduction performance, which result in the efficiency reduced about by 40 percent.

2, Economize the product’s cost, improve product's service life

a, When the production volume is large, the cost is lower than lathe processing heat sink, what’s more, the common section aluminum heat sinks are split-type, so they have to involve in artificial assembly costs.

b, We made a comparison in the common lathe processing section aluminum heat sinks, die casting heat sinks and cold forging unibody type heat sinks:

c, In the addition of the same size and shape, the cold forging unibody type heat sinks can be applied on bigger power appliance than the other heat sinks. For example, the common lathe processing