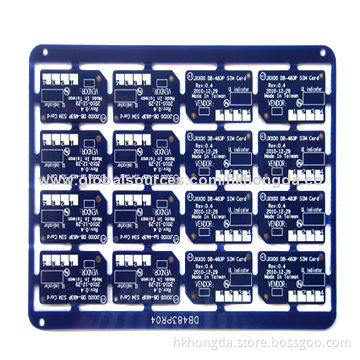

OEM Electronic PCB Assembly

- Payment Type:

- T/T

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Payment Type: | T/T |

|---|

Product Description

Product Description

- Efficient quotation, strict production, reliable quality

- Approval: UL, ISO9001

- Fast delivery

- PCBA, PCB board assembly: SMT, PTH and BGA

- PCBA and enclosure design

- Components sourcing and purchasing

- Quick prototyping

- Plastic injection molding

- Metal sheet stamping

- Final assembly

- Test: AOI, In-Circuit Test (ICT), Functional Test (FCT)

- Custom clearance for material importing and product exporting

- Lines: 9 (5 Yamaha, 4KME)

- Capacity: 52 million placements per month

- Maximum board size: 457*356mm (18x14")

- Minimum component size: 0201-54sq mm(0.084 sq inch), long connector, CSP, BGA, QFP

- Speed: 0.15sec/chip, 0.7sec/QFP

- Lines: 2

- Maximum board width: 400mm

- Type: dual wave

- PBS status: lead-free line support

- Maximum temperature: 399°C

- Spray flux: add-on

- Pre-heat: 3

- Checks for solder paste

- Checks for components down to 0201"

- Checks for missing components, offset, incorrect parts, polarity

- X-ray provides high-resolution inspection of:

- BGAs

- Micro BGAs

- Chip scale packages

- Bare boards

- Commonly used in conjunction with AOI minimizing functional defects caused by component problems

- Power-up test

- Advanced function test

- Flash device programming

- Functional testing

- BGAs

- Micro BGAs

- Chip scale packages

- Bare boards

Related Keywords

Related Keywords