Auto-punching Machine with Pneumatic Drive for Faceplate

- Payment Type:

- Telegraphic Transfer (TT, T/T)

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Payment Type: | Telegraphic Transfer (TT,T/T) |

|---|

Product Description

Product Description

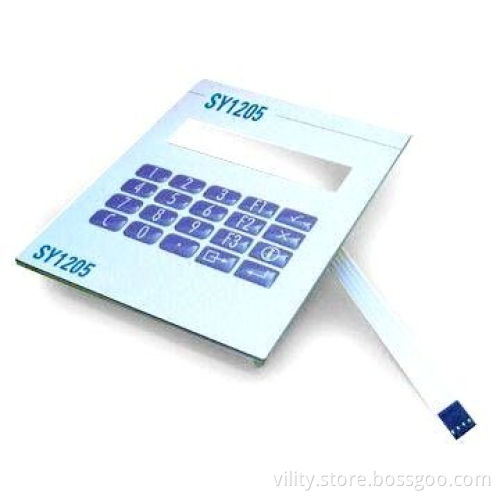

- Applies to different thickness of PCB, FPC IML/IMD, PVC/PET/PC panel, thin film switch, membrane panel and more

- The results are neither burrs nor enlargement surrounding processed holes

- Interactive-communication operational system with mouse operating tool (Microsoft Windows XP operating system) enables the procedure of the process to become easier, faster, and more efficient

- Large and wide operational stage enables the object to be moved and rotated easily

- High speed: super high punching speed enables the process of hole-recognizing and target-punching to be within one second

- Precise-transmission and micro-step motor driver is used to enhance accuracy and stability

- Up light or down light enables every materials of targeting holes to be identified easily and to enhance the accuracy of recognition in targeting shape

- No foot paddle is needed

- All the operation be finished by touch-screen

- It is sensitive enough to enhance the speed of operation

- Users can choose different tooling size to punch different diameter and thickness material

- Sampling plans can be saved, and then can be used directly next time

- Computer systems can supports software upgrade for life time

- In order to ensure long lifetime, the major components are imported oversea, such as relief valve, cylinder, and solenoid valve, rail and more

Related Keywords

Related Keywords

You May Also Like

You May Also Like