One-stop OEM service, Turkey PCB, GPS, Public Transportation System, Medical Equipment PCBA

- Payment Type:

- TT IN ADVANCE or LC at sight or Paypal

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Payment Type: | TT IN ADVANCE or LC at sight or Paypal |

|---|

Product Description

Product Description

- Rigid board Flex-(Rigid) board

- Layers 1-40 layers: 0-10/11-14 layers

- Max. working panel: 508x610(mm) 457x610 or 254x737(mm)

- Min. line width/spacing 3/3 mil for 0.5oz base copper 3/3 mil for 0.5oz base copper

- Min. hole size: 0.1mm for laser drill 0.20mm

- Copper thickness: 12-280um 12-105um

- Finished board thickness: 0.2-8.0mm 0.071-1.8mm

- Drill to copper; 7mil(min)

- Aspect ratio: 20:01 10:01

- Impedance control: 5% 10%

- High voltage test: 4000v

- Base material CEM1,CEM3,FR1,FR2,

- FR4,Halogen free FR4,High TG FR-4,Rogers,Getek, Arlon, Nelco, Rcc, Hy-bird, PTFE, PI

- Normal Surface finish HASL, Lead Free HASL, HASL, Lead Free HASL,

- ENIG, Imm.Sn, Imm.Ag, ENIG, Imm.Sn, Imm.Ag,

- OSP, Flash Gold, Hard Gold plated, Gold Finger OSP, Flash Gold, Hard Gold plated, Gold Finger, Silver Slurry

- Selective surface: HASL/LF HASL+ Gold Finger, HASL/LF HASL+ Gold Finger

- finish HASL/LF HASL+ENIG, HASL/LF HASL+ENIG

- ENIG/IMM.Sn/IMM.Ag+G/F ENIG/IMM.Sn/IMM.Ag+G/F

- ENIG+OSP ENIG+OSP

- OSP+G/F Silver Slurry+ Gold plated

- Silver Slurry+ ENIG

- Normal: IPC-A-600G class 2 IPC-A-600G class 2

- Advance: IPC-A-600G class 3 IPC-A-600G class 3

- Item Rigid board

- Normal Advance

- Inner layer registration: ±3mil

- Min. solder makes dam: 3mil 2.5mil

- Tolerance of line width/spacing: ±20% ±10%

- Tolerance of FBT : ±10% ±8%

- Min. QFP spacing: 20mil 16mil(not HASL)

- Tolerance of PTH: ±3mil ±2mil

- Tolerance of NPTH : ±2mil ±1mil

- Bow twist: 0.75%(max) 0.5%(max)

- Hole wall roughness: 1.5mil(max) 1mil(max)

- Outline tolerance: ±4mil ±3mil for routing

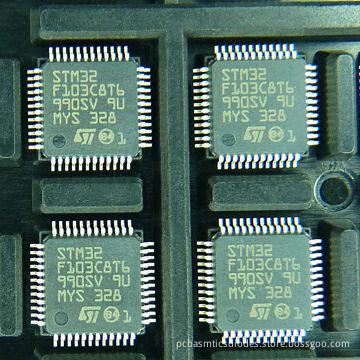

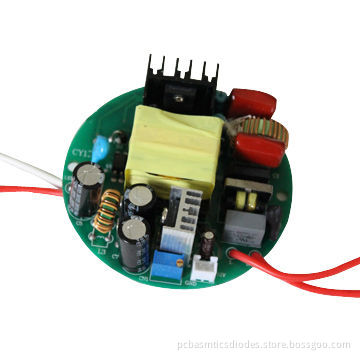

- Surface-mount

- Through-hole technologies

- Hand finish work

- Thru hole selective solder capabilities

- 0201 placement, fine pitch components (0.10" pitch)

- BGA assembly placement and rework capabilities

- Prototype Assembly

- Aqueous PCBA Cleaning

- X-Ray Verified PCBA and Inspection

- PCBA test analysis

- Box Build Assembly

- PCBA manufacturing consulting

- Cable and harness assemblies

Related Keywords

Related Keywords

You May Also Like

You May Also Like