Product Description

Product Description

Fabrication capacity: 3,000 tons a month

Experience: 20 years, established in 1989

Fabrication standard: GB50205:2002, AS/NZ4100, EN9001, AWSD1.1,D1.4, D1.5

Workshops area: 6 large span workshops 27 x 189 meters in 25,000 square meters

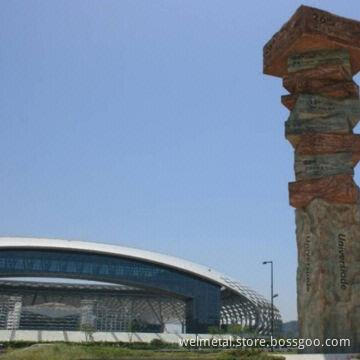

Projects fabrication scope: steel structures of constructions, infrastructure, equipment, such as airport, metro, bridge, hydropower station, stadium, equipment, warehouse, platform, stadium box beam, box column, welded beam, welded I-beam, H-beam, channel, butt weld, welded girder, girders and bracing, truss, bracing, curved truss beam, main and secondary truss beam steel structure, warehouse, buildings, equipment mold, steel dowel, screw pile, tower, steel frame and more

Production line machines: automatic arc submerge welding machines, CNC cutting machines, blasting machines, drilling machines, carbon dioxide arc welding machine, 32T cranes, press machine, purlin machines, H-beam strengthen machine, shearing stiffener cutting machines, blasting machines, assembling machines and more

Material: traceability, provide steel mill certificate

Welding processing and testing: fillet welding, full penetration welding, ultrasonic test

Coating treatment: galvanized, zinc rich epoxy primer

Inspection and testing: UT, tensile strength, bending, chemical composition analysis, dimension tolerance, coating and more

Qualification: WPS, weld workers operation certificate, NDT inspector, the third party

Packing: packing plan is confirmed by supplier and client, steel frame, wood, steel strip, pallet, box

Transportation: by containers or bulk carrier

ITP technical requirement from client