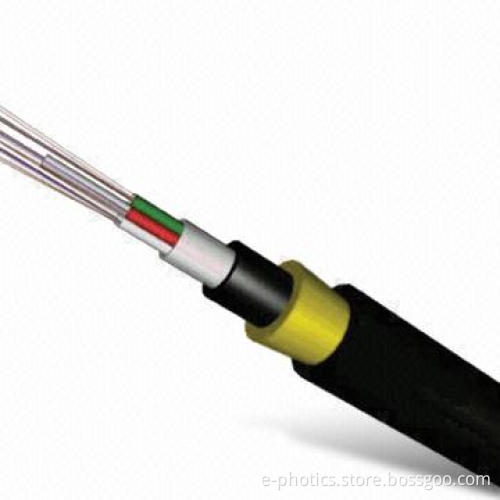

Fiber-optic Cable with Loose Tube Strands and Non-metallic Strengthening

- Payment Type:

- T/T or L/C

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Payment Type: | T/T or L/C |

|---|

Product Description

Product Description

- Loose tube stranded

- Fibers, 250μm, are positioned into loose tube made of high modulus plastics

- Tubes are filled with water-resistant filling compound

- Tubes (and fillers) are stranded around FRP (fiber reinforced plastic) as non-metallic central strength member into compact and circular cable core

- After cable core filled with filling compound, covered with thin PE (polyethylene) inner sheath

- After stranded layer of aramid yarns are applied over inner sheath as strength member, cable completed with PE or AT (anti-tracking) outer sheath

- Can be installed without shutting off the power

- Nice AT performance

- Maximum inductive at operating point of AT sheath can reach 25kV

- Lightweight and small diameter reducing load caused by ice, wind, load on towers & backdrops

- Large span lengths and largest span over 1,000m

- Nice performance of tensile strength and temperature

- Lifespan: over 30 years

- Actual status of overhead power lines taken into full consideration when ADSS cable being designed

- For overhead power lines under 110kV, PE outer sheath applied

- For power lines equal to or over 110kV, AT outer sheath applied

Related Keywords

Related Keywords

You May Also Like

You May Also Like