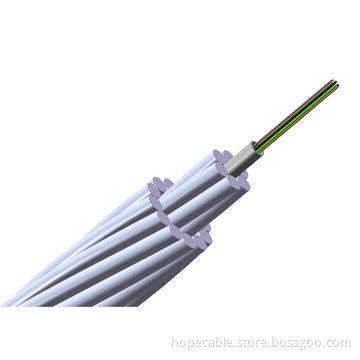

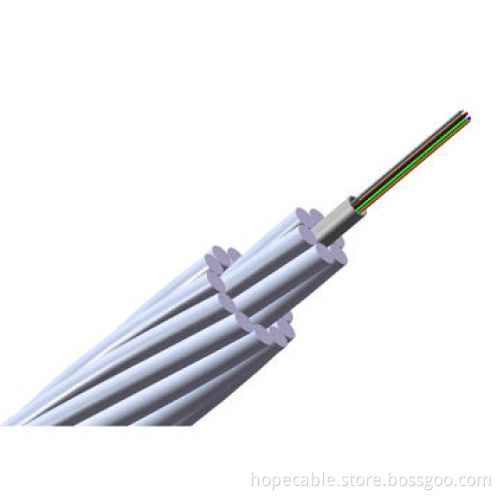

110~500KV 2-144 Cores Singel-mode/Multimode Central Loose Tube OPGW Fiber-optic Cable

- Payment Type:

- Telegraphic Transfer (TT, T/T)

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Payment Type: | Telegraphic Transfer (TT,T/T) |

|---|

Product Description

Product Description

- OPGW cable is mainly used in 500KV, 220KV and 110KV lines,

- limited by power cut, security and other elements, mostly used in new lines. Its applications are: high pressure over 110kv, with a longer span (usually over 250M);

- Easy to maintain, easy for line span, its mechanical property canmeet a big line span;

- Outer OPGW is metal armoring, with no influence for high pressure electro-corrosion and degradation;

- To construct OPGW must cut power, resulting in greater loss, thus OPGW must be used in constructing high pressure line over 110kv;

- For OPGW performance index, the more short circuit current, the more need a good conductor to be metal armor, and reduce tension strength, while, if the tension strength is certain, to increase short circuit current capacity, the only way is to enlarge metal section area, resulting in an increased cable Dia and weight, so that security is a question for line pole strength.

- Extruded Aluminum Core tube

- Good combination of crush and kink resistance

- Core tube can safely and easily be routed to closures without armor

- Easy access to optical core

- Meets IEEE construction guidelines for use in High Corrosion sites

- Superior Electrical Performance

- Aluminum core tube substantially increases conductor cross-section

- Improved short-circuit capacity

- Superior Lightning Resistance

- Fewer Aluminum Alloy (AA) wires are needed to meet electrical

- More/Heavier duty ACS wires can be used

- AA wires can be completely replaced with ACS in some applications

- High performance. Even in High fiber Counts

- All fibres are housed in the core tube

- Core tubes are available in a wide range of Inside Diameters

- Armor wires are not replaced with fiber tubes in high count designs

- Electrical and mechanical properties can be maintained.

Related Keywords

Related Keywords

You May Also Like

You May Also Like