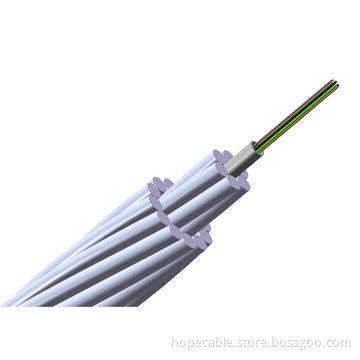

Stainless Steel Tube/Aluminum Wraping Steel Wire/Aluminum Alloy Wire/OPGW Communication Cable

- Payment Type:

- T/T, L/C

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Payment Type: | T/T, L/C |

|---|

Product Description

Product Description

- OPGW (optical fiber composited overhead ground wire), atech-product emerged in power industry in 1970s, is used to connect power and communication that are the world’s most important public networks, and has double functions of power ground wire and optical fiber communication

- With the breakthrough of key technology, high-intensity fiber, fill-jelly, seamless aluminum tube, aluminum-clad wire, and other advanced material are adopted for OPGW

- Bio-function of ground wire and communication cable, avoid a huge expenditure to re-erect and re-maintain

- Erect on top of power overhead line pole, need not to consider its best hanging point, electro-corrosion, and others

- In the process of old line transformation, cable’s outer diameter and tension may be matched better than another ground wire

- Big transmission capacity, good and reliable communication

- Excellent mechanical and electrical property;

- Good security, long lifetime, and invulnerable to gun fire.

- International standards: IEEE 1138; IEC 60794; IEC 60793; ITU-T Rec. G.650; ITU-T Rec. G.652 ITU-T Rec. G.655; ITU-T Rec. G.656; ITU-T Rec. G.657

- Typical structure and parameter of OPGW(L):

- Some structures and characteristics of typical representative OPGW are shown in the below list, however, they do not represent the whole products of the company

- OPGW cable is mainly used in 500KV, 220KV and 110KV lines, limited by power cut, security and other elements, mostly used in new lines. Its applications are: high pressure over 110kv, with a longer span (usually over 250M)

- Easy to maintain, easy for line span, its mechanical property can meet a big line span

- Outer OPGW is metal armoring, with no influence for high pressure electro-corrosion and degradation

- To construct OPGW must cut power, resulting in greater loss, thus OPGW must be used in constructing high pressure line over 110kv

- For OPGW performance index, the more short circuit current, the more need a good conductor to be metal armor, and reduce tension strength, while, if the tension strength is certain, to increase short circuit current capacity, the only way is to enlarge metal section area, resulting in an increased cable dia and weight, so that security is a question for line pole strength

Related Keywords

Related Keywords

You May Also Like

You May Also Like