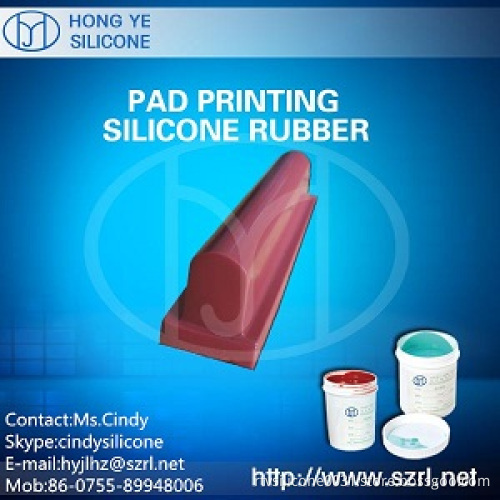

Liquid Pad Printing Silicone Rubber Material

- Payment Type:

- T/T, L/C, Western Union, Paypal

- Incoterm:

- FOB

- Min. Order:

- 200 Kilogram

- Min. Order:

- 200 Kilogram

- Delivery Time:

- 5 Days

- Transportation:

- Ocean, Air

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong, China |

|---|---|

| Productivity: | 8 Ton per Day |

| Supply Ability: | 8 Ton per Day |

| Payment Type: | T/T,L/C,Western Union,Paypal |

| Incoterm: | FOB |

| Certificate: | SGS, RoHS, MSDS, FDA, ISO, REACH, UL |

| Transportation: | Ocean,Air |

Liquid Pad Printing Silicone Rubber Material

Unit price:8-20usd/kg

Specification

- Durable

- Good effects for printing

- Good quality without any impurity

- Good resilience

- Adjustable hardness

Application

Pad printing silicone rubber is mainly use for printing irregular patterns of plastic toys, electroplating toys and trade makers.Pad printing silicone rubber as a carrier which transfer patterns on the steel plate to the toys products surface.

Features of liquid pad printing silicone rubber

a. resistance to deformation, high-temperature

b. high printing times

c. good aging resistance

d. exceptional elasticity

e. great printing effect

Operation Instructions

Pad printing silicone rubber is two-component silicone, part A is liquid silicon rubber, part B is catalyst. The usual mixture of silicone rubber and catalyst is 100: 2 or 100: 3. E.g. we take 100g of liquid silicon rubber and 2g-3g catalyst, mix them and pour it to your mold. After 2-4 hours, you will get a Pad printing silicone rubber.

Why the silicone pad is non-durable?

This problem is caused not by the liquid silicon rubber itself, but in the process of filtering, the filtering handled not properly and impurities are not all filtered out; or in the process of packing as containers not cleaned thoroughly.

As the silicon oil will break the molecular chain of the silicon rubber. More silicon oil added, softer the pad printing will be, meanwhile non-durable and easy aging it will also turn to be.

Some customers do not know well about the performance of silicon rubber. Actually, the durability of printing pad is closely related to the size of printing pattern. Some factories do not want to take the trouble to change the printing pad. While in fact, for large pattern, large silicone pads should be used, otherwise, use small one.(Generally, the ratio of the silicone pad to printing pattern is 3:1)

Related Keywords