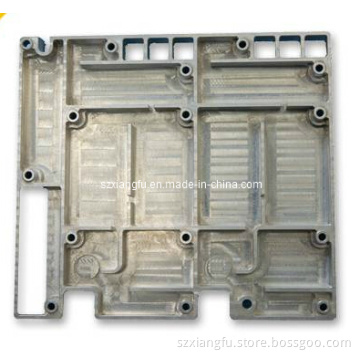

Zinc Die Casting Part, Pressure Die Casting Part

- Payment Type:

- T/T

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Shenzhen |

|---|---|

| Payment Type: | T/T |

Product Description

Product Description

1. Product range: Auto Parts, Furniture Parts, Communication Parts, Medical Parts, LED lamp fittings, Home Appliances&Electronic components, etc.

2. Product Material: Aluminum, Zinc

3. Surface treatment: Polishing, sand blasting, painting, powder coating, anodizing, electroplating, Chrome plating, mirror polishing, shot Blast, heat treatment.

4. Process: Sand casting, gravity casting, high pressure die casting, low pressure die casting and cnc machining casting.

5. Precision machining: Cnc turning, milling, drilling, grinding, cuting, reaming and threading.

6. Equipment: Die casting machine ranging from 280 to 2500T which are all imported from Swiss Buhler company and Hongkong LK machine company; Other production machines are Horizontal lathe, beam drilling machine, shaping machine, abrader, horizontal boring Machine, circular grinding, centerless grinder, surface grinding, digital wire cutting, threading machine, sewing machine, CNC lathe, 4 axes vertical and 4 horizontal machining centers.

About us:

We have a strong department, which can provide quick\accurate\one-stop service of development and design of some conceptual products, as well as mold making\hardware and plastic parts making and various processing techniques, such as oil injection\silk-screen\corrosion\electroplating\UV\oxidation treatment\wire drawing\sandblasting\polishing.

Customized specifications are accepted.

2. Product Material: Aluminum, Zinc

3. Surface treatment: Polishing, sand blasting, painting, powder coating, anodizing, electroplating, Chrome plating, mirror polishing, shot Blast, heat treatment.

4. Process: Sand casting, gravity casting, high pressure die casting, low pressure die casting and cnc machining casting.

5. Precision machining: Cnc turning, milling, drilling, grinding, cuting, reaming and threading.

6. Equipment: Die casting machine ranging from 280 to 2500T which are all imported from Swiss Buhler company and Hongkong LK machine company; Other production machines are Horizontal lathe, beam drilling machine, shaping machine, abrader, horizontal boring Machine, circular grinding, centerless grinder, surface grinding, digital wire cutting, threading machine, sewing machine, CNC lathe, 4 axes vertical and 4 horizontal machining centers.

About us:

We have a strong department, which can provide quick\accurate\one-stop service of development and design of some conceptual products, as well as mold making\hardware and plastic parts making and various processing techniques, such as oil injection\silk-screen\corrosion\electroplating\UV\oxidation treatment\wire drawing\sandblasting\polishing.

Customized specifications are accepted.

Related Keywords

Related Keywords