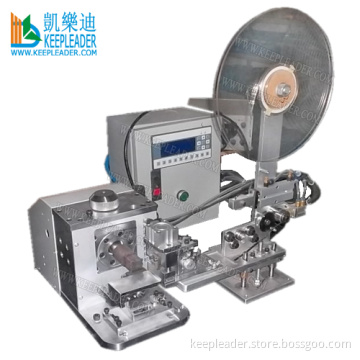

Battery Cell Resistance Spot Welder with Capacitors Discharged, 128 Programble

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Sz, Prc, Battery Resistance Spot Welder |

|---|---|

| Payment Type: | L/C, T/T, D/P, Paypal, Money Gram, Western Union |

Product Description

Product Description

resistance spot welding machine/battery cell/pack resistance spot welder/spot welding

KEEPLEADER SERVICE

ABOUT PRODUCT

Customized design; Safe and convenient operation

ABOUT FACTORY

Comprehensive management process, leading technology and service team

EXPERIENCE

Internationalization of business process; Rich experience of Non-standard design

AFTERSERVICE

Uniform standard with special difference for each, Professional and Experienced service

MARKET

Yearly 30% Market share increased, One-to-one service

KEEPLEADRE INTRODUCTION

HK KEEPLEADER CO.,LTD is a hi-tech joint venture, Located in Beautiful HongKong, was founded in 2009, now it has Sales office in Shenzhen, Shanghai and Beijing City, which is organized by SHENZHEN KEEPLEADER CO.,LTD to expand international Service and cooperation, we call it Marketing and Service Center, has recruited many well educated and qualified Engineers and Sales representatives, KEEPLEADER has its shareholding factory, is Mainly manufacturing Ultrasonic Cleaning Machine, Ultrasonic Welding Machine, High Frequency Welding Machine and peripheral machines concerning Ultrasonic and High Frequency Technology, KEEPLEADR Adopted Constructive and win-win nature of market model, Sales and Production is separated, by Which the customers to Maximize their protection of interest, in order to provide comprehensive ranges of solution, Basing on our Manufacture, HK KEEPLEADER has established Strategic partnership with many top-list factories in Shenzhen City and Dongguan City of Guangdong providing, Jinhua city and Ruian city of Zhejiang province, Wuxi, Changzhou city of Jiangsu province, The market Center has been dedicated to optimization and integration of developing, producing, marketing, service and application technology of ultrasonic and high frequency technology, and providing quality products and best solution for users, also has recruited many well educated and qualified engineers to keep our machine be fresh design, quality-improved, customized and easy-to-operate and maintenance, also many of experienced, down-to- earth sales representatives to provide good after service

Please contact KEEPLEADER for detailed info and tech evaluation for your app.

Please contact KEEPLEADER for detailed info and tech evaluation for your app.

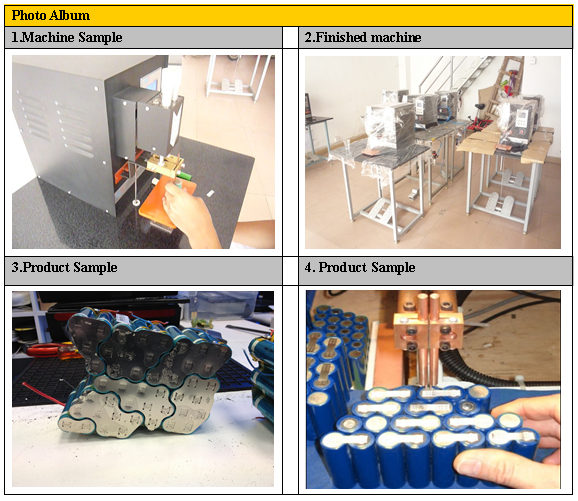

KEEPLEADER has designed and modified machine to accommodate our customers' unique and special requirements

and help us under info for further tech assistance

01: battery type

02: thickness of battery tab/connection sheet

03: sample picture of battery pack

04: Max size of battery pack

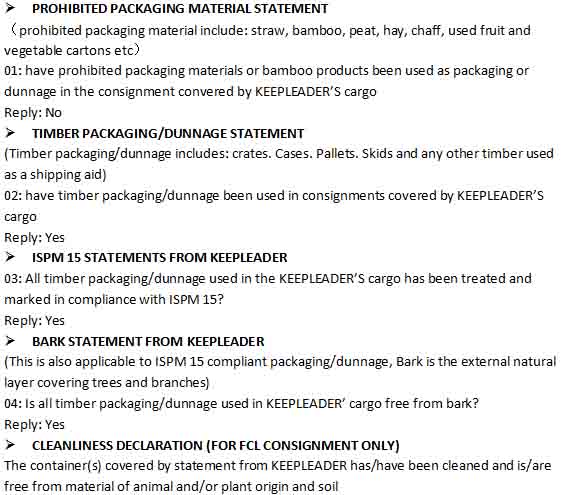

PACKAGING AND SHIPMENT

KEEPLEADER ADVANTAGES

KEEPLEADER ADVANTAGES

MFR: KEEPLEADER has modified and designed machine to accommodate our customers' unique and special requirements, pls contact KEEPLEADER with your detailed app for tech assessment

KEEPLEADER SERVICE

ABOUT PRODUCT

Customized design; Safe and convenient operation

ABOUT FACTORY

Comprehensive management process, leading technology and service team

EXPERIENCE

Internationalization of business process; Rich experience of Non-standard design

AFTERSERVICE

Uniform standard with special difference for each, Professional and Experienced service

MARKET

Yearly 30% Market share increased, One-to-one service

KEEPLEADRE INTRODUCTION

HK KEEPLEADER CO.,LTD is a hi-tech joint venture, Located in Beautiful HongKong, was founded in 2009, now it has Sales office in Shenzhen, Shanghai and Beijing City, which is organized by SHENZHEN KEEPLEADER CO.,LTD to expand international Service and cooperation, we call it Marketing and Service Center, has recruited many well educated and qualified Engineers and Sales representatives, KEEPLEADER has its shareholding factory, is Mainly manufacturing Ultrasonic Cleaning Machine, Ultrasonic Welding Machine, High Frequency Welding Machine and peripheral machines concerning Ultrasonic and High Frequency Technology, KEEPLEADR Adopted Constructive and win-win nature of market model, Sales and Production is separated, by Which the customers to Maximize their protection of interest, in order to provide comprehensive ranges of solution, Basing on our Manufacture, HK KEEPLEADER has established Strategic partnership with many top-list factories in Shenzhen City and Dongguan City of Guangdong providing, Jinhua city and Ruian city of Zhejiang province, Wuxi, Changzhou city of Jiangsu province, The market Center has been dedicated to optimization and integration of developing, producing, marketing, service and application technology of ultrasonic and high frequency technology, and providing quality products and best solution for users, also has recruited many well educated and qualified engineers to keep our machine be fresh design, quality-improved, customized and easy-to-operate and maintenance, also many of experienced, down-to- earth sales representatives to provide good after service

Please contact KEEPLEADER for detailed info and tech evaluation for your app.

Please contact KEEPLEADER for detailed info and tech evaluation for your app.KEEPLEADER has designed and modified machine to accommodate our customers' unique and special requirements

and help us under info for further tech assistance

01: battery type

02: thickness of battery tab/connection sheet

03: sample picture of battery pack

04: Max size of battery pack

PACKAGING AND SHIPMENT

KEEPLEADER ADVANTAGES

KEEPLEADER ADVANTAGESHas accumulated rich experience in Manufacturer by over ten years

Self-owned workshop and professional process equipment

Implementation of ISO9001:2000 quality management system

Independent operation of logistic, Sales, and Service Center

Professional managers, Co-ownership, liability partnership

Adopting Advanced ERP managing system

Resource sharing, information optimal configuration

Information can be tracked, responsible for each staffs, accountability

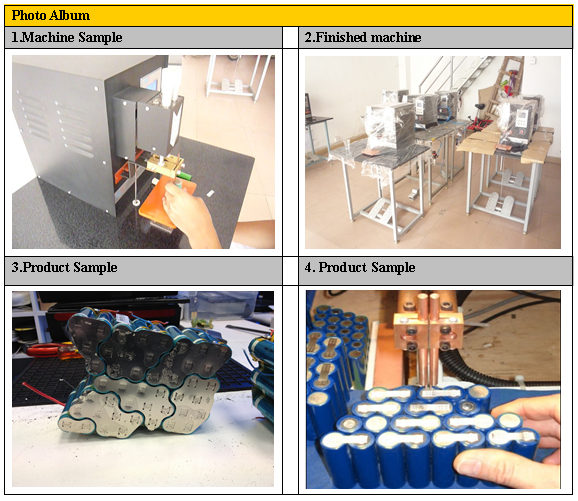

FINISHED PRODUCTS

KEEPLEADER CERTIFICATION

KEEPLEADER CERTIFICATION

CE EMC, CE LVD, RoHS, SGS

SECIFICATION OF BATTERY PACK RESISTANCE SPOT WELDER

FINISHED PRODUCTS

KEEPLEADER CERTIFICATION

KEEPLEADER CERTIFICATIONCE EMC, CE LVD, RoHS, SGS

SECIFICATION OF BATTERY PACK RESISTANCE SPOT WELDER

| Battery Cell energy storage resistance spot welder | |||||

| Application of battery cell DC resistance spot welder | |||||

| Communications equipment: battery combination, cell phone batteries, cell phone hardware Electronic Components: CRT devices, sensors, resistors, fuses, semiconductor components Appliance: metal piece to fix, heating piece Automobile making: flashing lights, relays, filaments Digital Products: laptop computers, digital cameras, MP3 batteries, computer memory heads and so on. electromechanical devices: contactors, circuit breakers, motors Metal Products: medical equipment, lamps, badge, headdress, jewelry and other aerospace, Precision metal parts, instrument, metal connectors, sensors, etc | |||||

| Character of resistance spot welder | |||||

| (single) double AC pulse energy storage welding, which is reliable for welding result CPU control, high definition LED display 240*64, the operation is visual and be more precision 128 user-defined welding procedures, all of them can be locked by manager State locking technology, which can avoid false triggering The unit can integrated into automatic production line Can set pedal switch to detect the welding parts before power generating Can set prepressing time before power discharge Radio (RFI) and electromagnetic interference (EMI) protection Power box and welding section are separated, which is safer Pneumatic and pedal control in one machine, which is more flexible Discharge time can be set between pulse 1 and pules 2 long, medium and short-pulse adjustable to fit fine welding | |||||

| Mainly parameter | |||||

| Rated power: 3.0 up 500watts/second (joule), the display screen can show the whole (maximum) energy percentage (%), the tolerance is 0.5%, the display screen is 0.1% up 0.5% in required energy Stability of power box: changes in the nominal voltage supply of +/- 13%, the power box can keep the voltage of capacity band at set value of +/-0.25% Display screen: the display screen adopts 240*64 high definition LCD, is visible for debugging Capacitor control circuit: when the voltage of error amplifier is over the required value to cut off charging circuit, one resistor connects at two sides of capacitor bank, by which let the voltage of capacitor bank work at required level, the dead zone of capacitor control circuit is about 0.6% of maximum voltage Line fault step-down: the is for safety purpose, when the power supply cut off suddenly, one resistor of voltage step-down automatic connects to release the power of capacitor bank Ignition circuit: Ignition requires an external account is closed or low-touch control logic circuit, inside filtering device can prevent electrical interference (RFI) triggered over ignition Power supply: 220v, AC, 50/60HZ, 2635watts rechargeable, 35wattes as spare, When 230V, 2A Cutout Welding ignition lock: error amplifier output, when charging and discharging to prevent ignition circuit, which is helpful to prevent to ignition before capacitor charging and discharging, the welding ignition lock circuit can prevent defected welding effect Programmable Prepressing time: combine with ignition welding head in the manual and automatic working mode without welding pressure, guarantee electrode is positioned well with welding parts before welding energy outputting, the prepressing time can be programmable (range:0.1 up 9.9 seconds) remote program selection: four monopole input: remote selection#1-#128 procedure; remote to prevent capacitor bank charging, when do remote program, the operation panel can be instead Valve drive output: can control electromagnetic valve of pneumatic welding head, 24VAC, 15A output Output pulse characteristic: at the side of power output, multiple a non-inductive load of 0.01 ohms, at both ends of it to measure pulse characteristics, to measure the rising time between zero amplitude and maximum point, to measure the pulse width at 10% amplitude point | |||||

| Pulse transformer | Capacitor bank | Rising time | Pulse width | Pulse amplitude | |

| Multiple(short) | 6000mfd | 1.7ms | 6.8ms | 9.5v | |

| series(long) | 6000mfd | 9.2ms | 2.7ms | 7.3v | |

| Welding speed: how many piece can be welded per minutes average when the machine work at rated status, | |||||

| Maximum energy percentage | Repeated welding Nos/minutes | Interrupted welding Nos/minutes | |||

| 2% under | 166 | 240 | |||

| 25% | 109 | 118 | |||

| 50% | 71 | 82 | |||

| 100% | 40 | 42 | |||

| Specifications | |||||

| Model | KLM-500 | ||||

| Rated power | 3.0-500w/s | ||||

| Drive Form | Pedal | ||||

| Welding Current | 0-99 Adjust | ||||

| Electrode Diameter | optional | ||||

| Input Power | AC220± 10%/50Hz | ||||

| Welding Power | DC | ||||

| Electrode Travel Length | 15mm | ||||

| Max Welding Thickness | 0.5mm | ||||

| Overall dimension | 310mm*280*430mm | ||||

| Net weight | 97kg | ||||

Related Keywords

Related Keywords

You May Also Like

You May Also Like