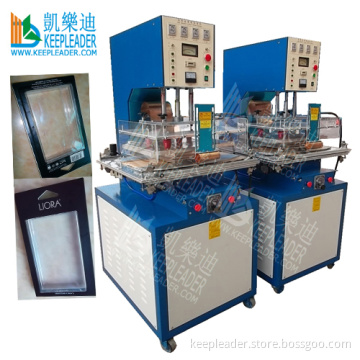

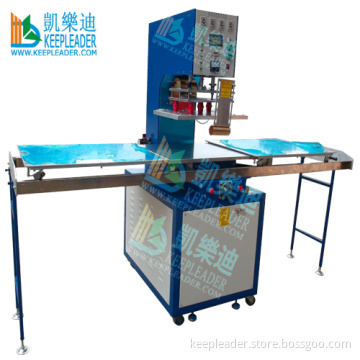

High Frequency Sealing Machine for Plastic Cylinder Box Bottom Welding

- Payment Type:

- L/C, T/T, Western Union

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Shenzhen, Prc, High Frequency Sealing Machine |

|---|---|

| Payment Type: | L/C, T/T, Western Union |

Product Description

Product Description

KEEPLEADER INTRODUCTION

HK KEEPLEADER CO.,LTD is a hi-tech joint venture, Located in Beautiful HongKong, was founded in 2009, now it has Sales office in Shenzhen, Shanghai and Beijing City, which is organized by SHENZHEN KEEPLEADER CO.,LTD to expand international Service and cooperation, we call it Marketing and Service Center, has recruited many well educated and qualified Engineers and Sales representatives, KEEPLEADER has its shareholding factory, is Mainly manufacturing Ultrasonic Cleaning Machine, Ultrasonic Welding Machine, High Frequency Welding Machine and peripheral machines concerning Ultrasonic and High Frequency Technology, KEEPLEADR Adopted Constructive and win-win nature of market model, Sales and Production is separated, by Which the customers to Maximize their protection of interest, in order to provide comprehensive ranges of solution, Basing on our Manufacture, HK KEEPLEADER has established Strategic partnership with many top-list factories in Shenzhen City and Dongguan City of Guangdong providing, Jinhua city and Ruian city of Zhejiang province, Wuxi, Changzhou city of Jiangsu province, The market Center has been dedicated to optimization and integration of developing, producing, marketing, service and application technology of ultrasonic and high frequency technology, and providing quality products and best solution for users, also has recruited many well educated and qualified engineers to keep our machine be fresh design, quality-improved, customized and easy-to-operate and maintenance, also many of experienced, down-to- earth sales representatives to provide good after service

KEEPLEADER SERVICE

High Frequency Blister Packaging Machine, plastic high frequency welding machine

Customized design; Safe and convenient operation

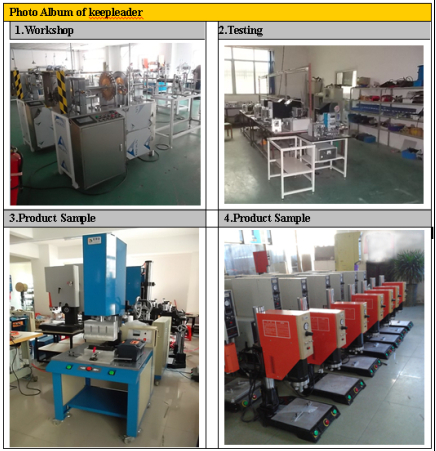

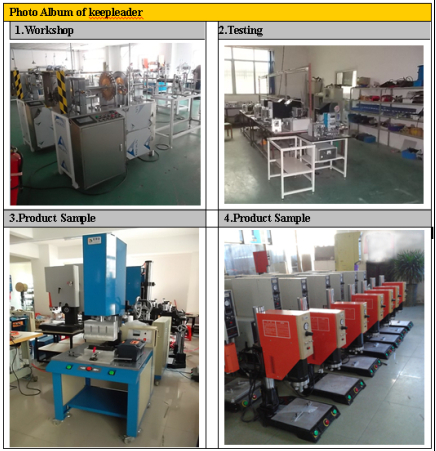

ABOUT FACTORY

Comprehensive management process, leading technology and service team

EXPERIENCE

Internationalization of business process; Rich experience of Non-standard design

AFTERSERVICE

Uniform standard with special difference for each, Professional and Experienced service

MARKET

Yearly 30% Market share increased, One-to-one service

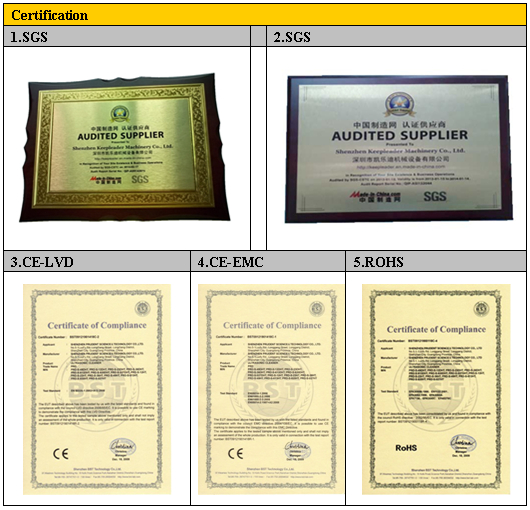

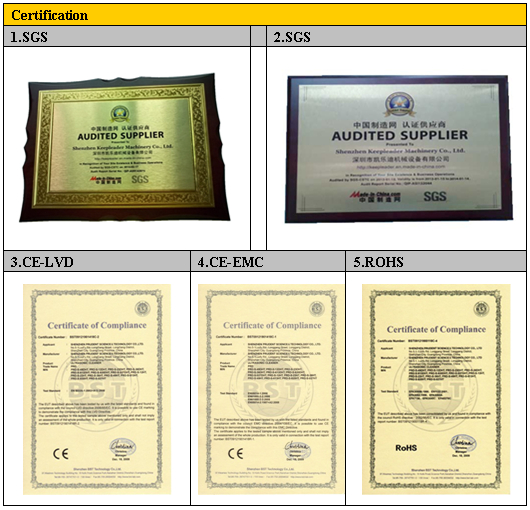

KEEPLEADER CERTIFICATION

FINISHED SAMPLES FROM KEEPLEADER

SPECIFICATION OF High frequency sealing machine

SPECIFICATION OF High frequency sealing machine

KEEPLEADER ADVANTAGES

HK KEEPLEADER CO.,LTD is a hi-tech joint venture, Located in Beautiful HongKong, was founded in 2009, now it has Sales office in Shenzhen, Shanghai and Beijing City, which is organized by SHENZHEN KEEPLEADER CO.,LTD to expand international Service and cooperation, we call it Marketing and Service Center, has recruited many well educated and qualified Engineers and Sales representatives, KEEPLEADER has its shareholding factory, is Mainly manufacturing Ultrasonic Cleaning Machine, Ultrasonic Welding Machine, High Frequency Welding Machine and peripheral machines concerning Ultrasonic and High Frequency Technology, KEEPLEADR Adopted Constructive and win-win nature of market model, Sales and Production is separated, by Which the customers to Maximize their protection of interest, in order to provide comprehensive ranges of solution, Basing on our Manufacture, HK KEEPLEADER has established Strategic partnership with many top-list factories in Shenzhen City and Dongguan City of Guangdong providing, Jinhua city and Ruian city of Zhejiang province, Wuxi, Changzhou city of Jiangsu province, The market Center has been dedicated to optimization and integration of developing, producing, marketing, service and application technology of ultrasonic and high frequency technology, and providing quality products and best solution for users, also has recruited many well educated and qualified engineers to keep our machine be fresh design, quality-improved, customized and easy-to-operate and maintenance, also many of experienced, down-to- earth sales representatives to provide good after service

KEEPLEADER SERVICE

High Frequency Blister Packaging Machine, plastic high frequency welding machine

Customized design; Safe and convenient operation

ABOUT FACTORY

Comprehensive management process, leading technology and service team

EXPERIENCE

Internationalization of business process; Rich experience of Non-standard design

AFTERSERVICE

Uniform standard with special difference for each, Professional and Experienced service

MARKET

Yearly 30% Market share increased, One-to-one service

KEEPLEADER CERTIFICATION

FINISHED SAMPLES FROM KEEPLEADER

SPECIFICATION OF High frequency sealing machine

SPECIFICATION OF High frequency sealing machine| Main application | |

| Applied for blister sealing and cutting edges by high frequency welding technology, PVC blister sealing, PVC clamshell sealing, PVC Blister sealing on heating activated coating cardboard, PVC thermoformed box sealing, welding and cutting for any shape products made of PVC or PVC 30% up in membrane structure | |

| Character | |

| High Q value oscillation tube, reliable and strong output high frequency complies with international standard: 27.12 MHz The machine can keep static for power sudden failure High sensitive anti-sparkle device NL 5557 to avoid damaging the mould. High quality Imported apparatus European-model high frequency vibration barrel, more reliable and stable Automatic thermostat to keep the temperature at best performance in welding High precision high frequency regulating knob for visible control Low voltage control panel for safety purpose Anodized mould and tooling for longer life-span Over current protection circuit to avoid burning the oscillation tube Power ranges 5kw up to 10kw for various welding size The welding electrode is screw fixed, which is easy replacement High frequency shield to avoid omission is optional Stroke distance and horizontal of electrode are adjustable Pedal valve control and button switches control are optional Thick steel plate bracket, more steady for giving pressure Imported famous brand electronic and pneumatic components Three or four working position is optional High precision cam/divider | |

| Mainly parameter | |

| Model | KLR-5000E |

| Power | 5000W |

| Voltage | 220V/380V 50/60HZ |

| Frequency | 27.12MHZ |

| Input power | 8KVA |

| Rectifier | SILICON DIODE |

| Oscillation tube | 7T85RB |

| Max pressure | 350kg |

| The gap of electrode | 160~200MM |

| Stroke distance | 200MM |

| upper electrode | 200*350mm |

| lower electrode | 400*600mm |

| Welding time | 0 up to 10s adjustable |

| Productivity | 4000times/8h |

| Net weight | 400kgs |

| Overall dimension | 1000*660*1730 |

Has accumulated rich experience in Manufacturer by over ten years

Self-owned workshop and professional process equipment

Implementation of ISO9001:2000 quality management system

Independent operation of logistic, Sales, and Service Center

Professional managers, Co-ownership, liability partnership

Adopting Advanced ERP managing system

Resource sharing, information optimal configuration

Information can be tracked, responsible for each staffs, accountability

Related Keywords

Related Keywords

You May Also Like

You May Also Like