Skymen Ultrasonic Cleaning Tank Ultrasonic Cavitation with Oil Filtration

- Payment Type:

- T/T, Paypal, Money Gram, Western Union

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Shenzhen |

|---|---|

| Payment Type: | T/T, Paypal, Money Gram, Western Union |

Product Description

Product Description

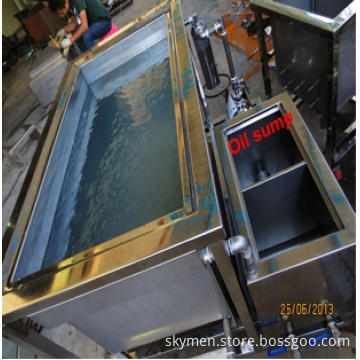

Skymen ultrasonic cleaning tank ultrasonic cavitation with oil filtration

Professional use for remove heavy oil and carbon from industrial component. Such as diesel parts, engine block clean, even no problem for heavily oil and grease. High efficient for you to save time and labor cost.

Advantages of the ultrasonic cleaning machine:

1 tank size can be customized

2 ultrasonic power can be customized

3 the cleaner is equipped with wheel-to remove easily

4 with drainage

5 with lid to reduce noise

6 1 year after-service

7 filtration system is available

JTS-1060

Specification details:

Tank's working dimension (mm): 1000*600*500(L*W*H)

Tank's total capacity: 300L

Tank's material: SUS304 / SUS316L

In-tank surface finishing: Hard-Cr Plating Treatment ( 20+ microns )

Housing's material: Stainless steel

Ultrasonic frequency: 28kHz / 40kHz

Ultrasonic transducer: 60

Ultrasonic output power (MAX. ): 1500W

Electronic generator: KG1500

Heater's (hot plate) power: 7.5kW

Generator's power requirement: AC 220V / 240V, 1, 13AMP

Features:

Adjustable ultrasonic power

Original BLT type transducer

SUS 304/316L stainless steel tank

Adaptable for continuous operation

Adjustable thermo controller

Adjustable ultrasonic power

With separate control ultrasonic electronic generator

Sweep mode control available

Digital timer & heating control

Boost mode& oil skimmer upon clients requirement

Pressure pump and filter system are available

Functions:

JTS series single tank ultrasonic cleaner equipment system includes replaceable transducer box and generator. The transducer box and generator can be both build-in or separate but work together to operate ultrasonic cleaning process with transducer box immersible mounted in fluid tank, one side or both side or bottom mounted inside the tank. The number and placement of transducers is selected to give maximum results in any parts cleaning tank with any cleaning load. Specification of tank dimension and transducer boxes are custom made available. Either for mould of parts cleaning can receive perfect cleaning efficiency. Stainless steel basket is optional.

Professional use for remove heavy oil and carbon from industrial component. Such as diesel parts, engine block clean, even no problem for heavily oil and grease. High efficient for you to save time and labor cost.

Advantages of the ultrasonic cleaning machine:

1 tank size can be customized

2 ultrasonic power can be customized

3 the cleaner is equipped with wheel-to remove easily

4 with drainage

5 with lid to reduce noise

6 1 year after-service

7 filtration system is available

JTS-1060

Specification details:

Tank's working dimension (mm): 1000*600*500(L*W*H)

Tank's total capacity: 300L

Tank's material: SUS304 / SUS316L

In-tank surface finishing: Hard-Cr Plating Treatment ( 20+ microns )

Housing's material: Stainless steel

Ultrasonic frequency: 28kHz / 40kHz

Ultrasonic transducer: 60

Ultrasonic output power (MAX. ): 1500W

Electronic generator: KG1500

Heater's (hot plate) power: 7.5kW

Generator's power requirement: AC 220V / 240V, 1, 13AMP

Features:

Adjustable ultrasonic power

Original BLT type transducer

SUS 304/316L stainless steel tank

Adaptable for continuous operation

Adjustable thermo controller

Adjustable ultrasonic power

With separate control ultrasonic electronic generator

Sweep mode control available

Digital timer & heating control

Boost mode& oil skimmer upon clients requirement

Pressure pump and filter system are available

Functions:

JTS series single tank ultrasonic cleaner equipment system includes replaceable transducer box and generator. The transducer box and generator can be both build-in or separate but work together to operate ultrasonic cleaning process with transducer box immersible mounted in fluid tank, one side or both side or bottom mounted inside the tank. The number and placement of transducers is selected to give maximum results in any parts cleaning tank with any cleaning load. Specification of tank dimension and transducer boxes are custom made available. Either for mould of parts cleaning can receive perfect cleaning efficiency. Stainless steel basket is optional.

Related Keywords

Related Keywords

You May Also Like

You May Also Like