Anti Reflective Glass for Tempered Glass Screen Protector

- Payment Type:

- L/C, T/T, Western Union

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Guangdong Guangzhou |

|---|---|

| Payment Type: | L/C, T/T, Western Union |

Product Description

Product Description

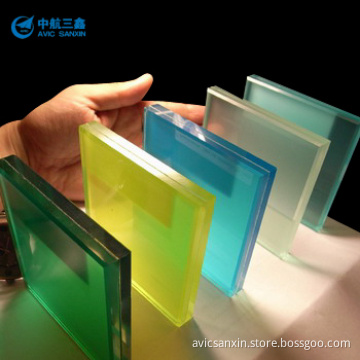

Anti reflective glass for Tempered glass screen protector

1. Basic Concept:

AR coated glass is also called add-transmissivity glass, anti reflective glass. Adopting advanced magnetron sputtering vacuum coating technology, coating the Nano optics multilayer film on the glass surface, it can enhance the transmissivity of glass from 89% to more than 96% and reflectivity from 8% to less than 2%, for examples, four layers AR film on double surfaces, the transmissivity can be over 98%, the reflectivity can be lower 1%, no reflect and anti giddy light, it makes image more clear with the strong light and improves the screen brightness to protect your eyes.

Transmission rate is up to more than 96%(Max: 99.5%) from common glass 89%, and its the world's most transparent glass.

Reflectivity from 8% of the common glass fell below 2% (Min: 0.2%), Effectively weaken the defects caused by strong light behind the picture, Enjoy a more clear image quality.

Uv spectral transmittance < 3%, which can effectively block the ultraviolet ray injuries to the eyes.

Excellent scratch resistance and hardness≥ 7H, Excellent environmental performance, pass the acid and alkali resistance, solvent resistance, temperature cycle, high temperature test, and membrane layer has no obvious change.

2. Application:

AR glass is mainly used for display device, such as LCD TV, PDP TV, laptop, desktop computer monitor, instrument panel, touch screen, picture frame glass and other electronic products to improve the transmission rate lower reflectivity, avoiding image being influenced by backside strong light, enjoying more clear image.

3. Film structure:

1): Single surface AR(double layer) GLASS\TIO2\SIO2

2): Double surface AR (four layer) GLASS\TI02\SIO2\TIO2\SIO2

3): Multilayer AR-Base on client requests

4. Processing size:

Max: 1600 mmx2800mm Min: 200mmx200 mm Thickness: 0.4mm--6mm (according to customers' requirements)

5. Toughened standards:

GB/T9963-1998 BS6206 ANSI Z97.1-2004 EN12150

1. Basic Concept:

AR coated glass is also called add-transmissivity glass, anti reflective glass. Adopting advanced magnetron sputtering vacuum coating technology, coating the Nano optics multilayer film on the glass surface, it can enhance the transmissivity of glass from 89% to more than 96% and reflectivity from 8% to less than 2%, for examples, four layers AR film on double surfaces, the transmissivity can be over 98%, the reflectivity can be lower 1%, no reflect and anti giddy light, it makes image more clear with the strong light and improves the screen brightness to protect your eyes.

Transmission rate is up to more than 96%(Max: 99.5%) from common glass 89%, and its the world's most transparent glass.

Reflectivity from 8% of the common glass fell below 2% (Min: 0.2%), Effectively weaken the defects caused by strong light behind the picture, Enjoy a more clear image quality.

Uv spectral transmittance < 3%, which can effectively block the ultraviolet ray injuries to the eyes.

Excellent scratch resistance and hardness≥ 7H, Excellent environmental performance, pass the acid and alkali resistance, solvent resistance, temperature cycle, high temperature test, and membrane layer has no obvious change.

2. Application:

AR glass is mainly used for display device, such as LCD TV, PDP TV, laptop, desktop computer monitor, instrument panel, touch screen, picture frame glass and other electronic products to improve the transmission rate lower reflectivity, avoiding image being influenced by backside strong light, enjoying more clear image.

3. Film structure:

1): Single surface AR(double layer) GLASS\TIO2\SIO2

2): Double surface AR (four layer) GLASS\TI02\SIO2\TIO2\SIO2

3): Multilayer AR-Base on client requests

4. Processing size:

Max: 1600 mmx2800mm Min: 200mmx200 mm Thickness: 0.4mm--6mm (according to customers' requirements)

5. Toughened standards:

GB/T9963-1998 BS6206 ANSI Z97.1-2004 EN12150

Related Keywords

Related Keywords

You May Also Like

You May Also Like