Contactless Card Prelam

- Payment Type:

- T/T, Paypal, Western Union

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Shenzhen |

|---|---|

| Payment Type: | T/T, Paypal, Western Union |

Product Description

Product Description

RFID Card Production supplier

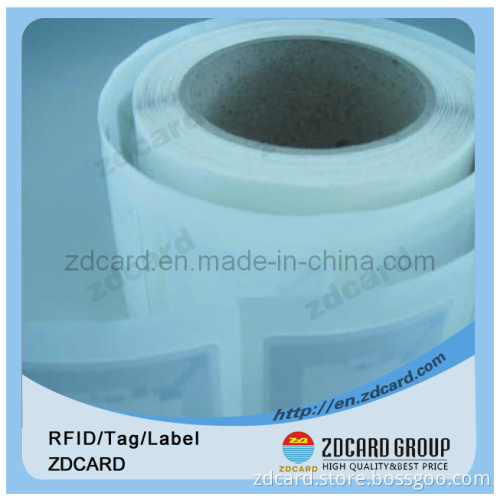

Contactless Card Prelam:

ZDCARD provides card manufactures with a reliable and convenient semi-product for the manufacture of finished contactless cards, Prelam stands for Pre-laminated.

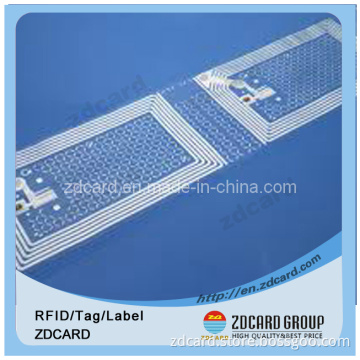

ZDCARDprelam is fusing together of the different layers of thermoplastic material into one homogeneous sheet, sealed RFID transponder parts hermetically. After the RFID transponder parts have been embedded into the carrier material and assembled.

Then card manufactures could made card by single layer of prelam fused together the both side of preprinting layer under pressure and high temperature in lamination press machinery to embedding RFID carrier and assembling a finished contactless RFID card.

This pre-laminated or prelam structure is ideal for making pre-printed cards with many security features using standard card

Production processes.

ZDCARDprelam could incorporate pre-winding coil or ultrasonic embedding copper antenna, even FLIP chip etching antenna upon the customer's requirements. The prelam can be made of material PVC, PET or ABS.

We could develop any size and shape of antenna can be adapted to the specific requirements of the customer. Customers can also select different sheet formats such as 2X4, 2X5, 3X7, 4X5, 5X5, 4X8 or other customized layouts. To facilitate card production, our prelam come with trimmed reference edges and optional printed cross marks and registration holes.

Reliability, durability and prefect electrical performance, compliant with divers standards, ZDCARDprelam is ideal semi-products for laminating contactless card, tag applications such as automated fare collection, access control, ePayment and identification.

Contactless Card Prelam:

ZDCARD provides card manufactures with a reliable and convenient semi-product for the manufacture of finished contactless cards, Prelam stands for Pre-laminated.

ZDCARDprelam is fusing together of the different layers of thermoplastic material into one homogeneous sheet, sealed RFID transponder parts hermetically. After the RFID transponder parts have been embedded into the carrier material and assembled.

Then card manufactures could made card by single layer of prelam fused together the both side of preprinting layer under pressure and high temperature in lamination press machinery to embedding RFID carrier and assembling a finished contactless RFID card.

This pre-laminated or prelam structure is ideal for making pre-printed cards with many security features using standard card

Production processes.

ZDCARDprelam could incorporate pre-winding coil or ultrasonic embedding copper antenna, even FLIP chip etching antenna upon the customer's requirements. The prelam can be made of material PVC, PET or ABS.

We could develop any size and shape of antenna can be adapted to the specific requirements of the customer. Customers can also select different sheet formats such as 2X4, 2X5, 3X7, 4X5, 5X5, 4X8 or other customized layouts. To facilitate card production, our prelam come with trimmed reference edges and optional printed cross marks and registration holes.

Reliability, durability and prefect electrical performance, compliant with divers standards, ZDCARDprelam is ideal semi-products for laminating contactless card, tag applications such as automated fare collection, access control, ePayment and identification.

Related Keywords

Related Keywords

You May Also Like

You May Also Like