Closed Loop NEMA34 Stepper Motor, NEMA34 Closed Loop Hybrid Stepping Motor Manufacturing

- Payment Type:

- T/T, Paypal, Western Union

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Shenzhen |

|---|---|

| Payment Type: | T/T, Paypal, Western Union |

Product Description

Product Description

Closed loop Nema34 stepper motor, nema34 closed loop hybrid stepping motor manufacturing

1). Low noise

2). Stable operation

3). High torque

Full closed loop

1, accurate location and speed control to meet the most demanding application requirements

2, high robustness of servo drive control can adapt to a wide range of inertia load and friction load change

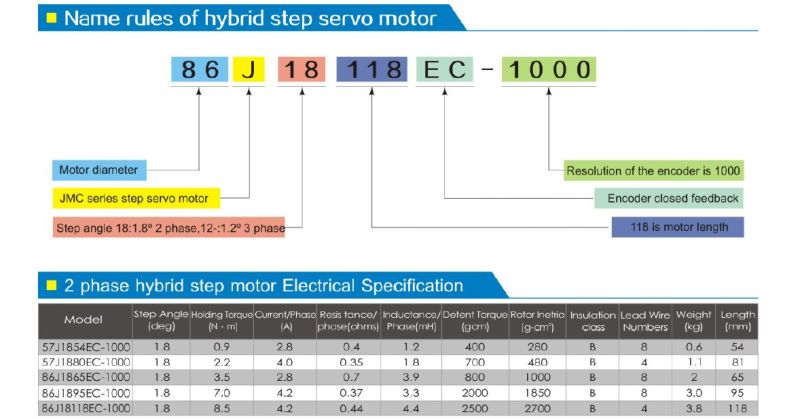

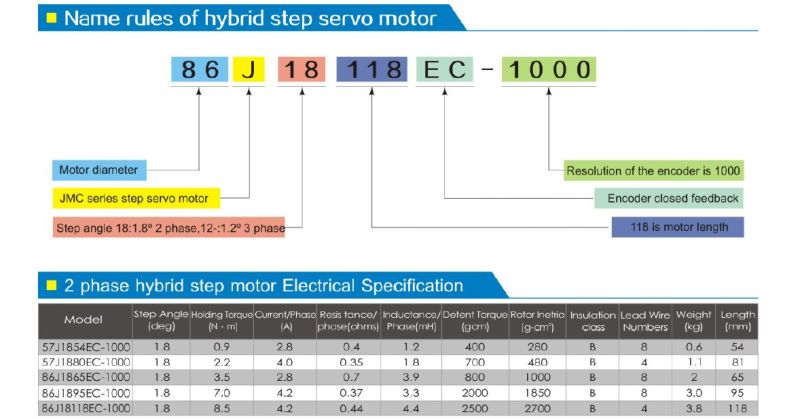

3, the motor with standard 1000 line encoder, support vector closed loop control, and to tackle fundamentally the traditional stepping

Motor lose step problem.

Low fever/high efficiency

1, according to the actual load condition real-time adjustment current size, will fever drop to the minimum

2, stationary, current is almost zero, no fever.

3, close to 100% torque output ability, in the most compact space in the play Big energy conversion, the energy saving efficiency.

Smooth accurate

Based on the feedback encoder space vector current control algorithm and vector smoothing filtering technology, for the problem of traditional stepping motor "low frequency resonance" have very good resist effect. So as to realize the electric Machine in the low speed application still

Can keep the stable and quiet operation. Perfect solution traditional stepping motor low speed vibration noise problem.

1, mixed servo system retained the traditional open loop stepping system some advantages, Position respond to the input and output command signal is almost real time synchronization, so Very suitable for short distance fast start-stop and zero speed stability to stop occasions.

2, in point to point fast fast positioning movement situation, advanced servo control Technology provides the big torque output, the system has a very high dynamic response. Far beyond the traditional step system limit.

1). Low noise

2). Stable operation

3). High torque

Full closed loop

1, accurate location and speed control to meet the most demanding application requirements

2, high robustness of servo drive control can adapt to a wide range of inertia load and friction load change

3, the motor with standard 1000 line encoder, support vector closed loop control, and to tackle fundamentally the traditional stepping

Motor lose step problem.

Low fever/high efficiency

1, according to the actual load condition real-time adjustment current size, will fever drop to the minimum

2, stationary, current is almost zero, no fever.

3, close to 100% torque output ability, in the most compact space in the play Big energy conversion, the energy saving efficiency.

Smooth accurate

Based on the feedback encoder space vector current control algorithm and vector smoothing filtering technology, for the problem of traditional stepping motor "low frequency resonance" have very good resist effect. So as to realize the electric Machine in the low speed application still

Can keep the stable and quiet operation. Perfect solution traditional stepping motor low speed vibration noise problem.

1, mixed servo system retained the traditional open loop stepping system some advantages, Position respond to the input and output command signal is almost real time synchronization, so Very suitable for short distance fast start-stop and zero speed stability to stop occasions.

2, in point to point fast fast positioning movement situation, advanced servo control Technology provides the big torque output, the system has a very high dynamic response. Far beyond the traditional step system limit.

Related Keywords

Related Keywords

You May Also Like

You May Also Like