Rubber-Component Silicone for Gypsum Mould Making

- Payment Type:

- L/C, T/T, Western Union

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Shenzhen |

|---|---|

| Payment Type: | L/C, T/T, Western Union |

Product Description

Product Description

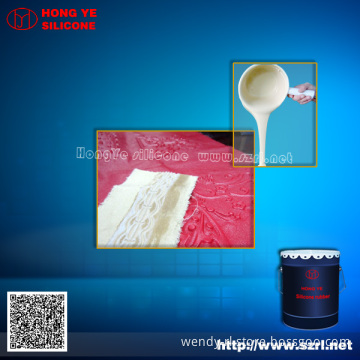

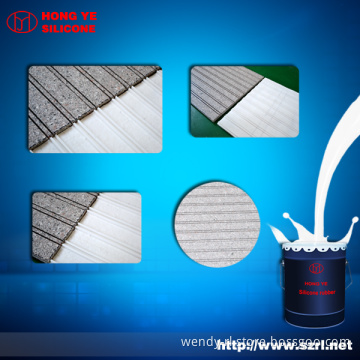

Rubber-Component Silicone for Gypsum Mould Making applications:

Rubber-Component Silicone for Gypsum Mould Making good for:

1. Statues, prefabricated concrete, fountains and garden articles,

2. Rosettes, cornices, sanitary fixtures, decorative pottery,

3. Giftware, industrial equipment, decorative candles, gaskets, mechanical components

4. Also for soles footwear, archaeological findings or automotive prototypes mold making.

Rubber-Component Silicone for Gypsum Mould Making silicone

1. Deal with original moulds

2. Brush on release agent

3. Correct weigh accoring to mixng ratio

4. Stir the two component evenly

5. Vacuum-pumping

6. Pouring

Rubber-Component Silicone for Gypsum Mould Making Features:

(1) RTV silicon rubber with SGS, REACH and RoHS approval

(2) Curing agent arrange together as free charged

(3) In liquid form and in various colors

(4) With an exceptional fluidity and good operability.

(5) Temperature and deformation resistance as well as low shrinkage.

(6) High duplication times.

(7) Sample orders are available

(8) MOQ: 100KG

Storage and Precautions of Rubber-Component Silicone for Gypsum Mould Making

Rubber-Component Silicone for Gypsum Mould Making, which is an environmentally-friendly liquid silicone product, is not easy to burn and can be stored and transported as non-hazardous goods. The shelf life of the product is about one year from the date of production. Inspection is required when exceeding the time limited. It can continue to be used in case of neither thickening nor deterioration.

Need more information about RUBBER-component silicone, please feel free to contact us anytime.

Rubber-Component Silicone for Gypsum Mould Making good for:

1. Statues, prefabricated concrete, fountains and garden articles,

2. Rosettes, cornices, sanitary fixtures, decorative pottery,

3. Giftware, industrial equipment, decorative candles, gaskets, mechanical components

4. Also for soles footwear, archaeological findings or automotive prototypes mold making.

Rubber-Component Silicone for Gypsum Mould Making silicone

1. Deal with original moulds

2. Brush on release agent

3. Correct weigh accoring to mixng ratio

4. Stir the two component evenly

5. Vacuum-pumping

6. Pouring

Rubber-Component Silicone for Gypsum Mould Making Features:

(1) RTV silicon rubber with SGS, REACH and RoHS approval

(2) Curing agent arrange together as free charged

(3) In liquid form and in various colors

(4) With an exceptional fluidity and good operability.

(5) Temperature and deformation resistance as well as low shrinkage.

(6) High duplication times.

(7) Sample orders are available

(8) MOQ: 100KG

Storage and Precautions of Rubber-Component Silicone for Gypsum Mould Making

Rubber-Component Silicone for Gypsum Mould Making, which is an environmentally-friendly liquid silicone product, is not easy to burn and can be stored and transported as non-hazardous goods. The shelf life of the product is about one year from the date of production. Inspection is required when exceeding the time limited. It can continue to be used in case of neither thickening nor deterioration.

Need more information about RUBBER-component silicone, please feel free to contact us anytime.

Related Keywords

Related Keywords

You May Also Like

You May Also Like