Pad Printing Silicon Rubber (912#)

- Payment Type:

- L/C, T/T

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Payment Type: | L/C, T/T |

Product Description

Product Description

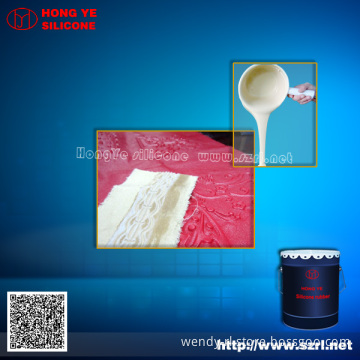

Pad Printing Silicon Rubber

Applications of Pad Printing Silicon Rubber:

Pad printing silicone rubber is mainly applicable to the printing of irregular patterns on plastics toys, electroplating products, electronic toys, trademarks, artwork gifts, and stationery, etc. We use Pad printing silicon rubber to make silicone pad. The silicon pad is a carrier which transfers the patterns from the steel plate onto the products surface.

Features of Pad Printing Silicon Rubber:

Pad printing silicon rubber has the advantage of good printing effects, fine quality, favorible resilience, high print times and without any impurity.

Specifications of Pad Printing Silicon Rubber:

902# Pad Printing Silicon Rubber

912# Pad Printing Silicon Rubber

916# Pad Printing Silicon Rubber

918# Pad Printing Silicon Rubber

FOQ of Pad printing silicone rubber:

Why the silicon pad is non-durable?

Firstly, this problem is caused by the liquid silicon rubber itself, in the process of filtering, the filtering handled not properly and impurities are not all filtered out; Or in the process of packing as containers not cleaned thoroughly.

Secondly, as the silicon oil will break the molecular chain of the silicon rubber. More silicon oil added, softer the pad printing will be, meanwhile nondurable and easy ageing it will also turn to be.

Thirdly, some customers do not know well about the performance of silicon rubber. Actually, the durability of printing pad is closely related to the size of printing pattern. Some factories do not want to take the trouble to change the printing pad. While in fact, for large pattern, large silicone pads should be used, otherwise, use small one. (Generally, the ratio of the silicone pad to printing pattern is 3: 1)

Applications of Pad Printing Silicon Rubber:

Pad printing silicone rubber is mainly applicable to the printing of irregular patterns on plastics toys, electroplating products, electronic toys, trademarks, artwork gifts, and stationery, etc. We use Pad printing silicon rubber to make silicone pad. The silicon pad is a carrier which transfers the patterns from the steel plate onto the products surface.

Features of Pad Printing Silicon Rubber:

Pad printing silicon rubber has the advantage of good printing effects, fine quality, favorible resilience, high print times and without any impurity.

Specifications of Pad Printing Silicon Rubber:

902# Pad Printing Silicon Rubber

912# Pad Printing Silicon Rubber

916# Pad Printing Silicon Rubber

918# Pad Printing Silicon Rubber

FOQ of Pad printing silicone rubber:

Why the silicon pad is non-durable?

Firstly, this problem is caused by the liquid silicon rubber itself, in the process of filtering, the filtering handled not properly and impurities are not all filtered out; Or in the process of packing as containers not cleaned thoroughly.

Secondly, as the silicon oil will break the molecular chain of the silicon rubber. More silicon oil added, softer the pad printing will be, meanwhile nondurable and easy ageing it will also turn to be.

Thirdly, some customers do not know well about the performance of silicon rubber. Actually, the durability of printing pad is closely related to the size of printing pattern. Some factories do not want to take the trouble to change the printing pad. While in fact, for large pattern, large silicone pads should be used, otherwise, use small one. (Generally, the ratio of the silicone pad to printing pattern is 3: 1)

Related Keywords

Related Keywords

You May Also Like

You May Also Like