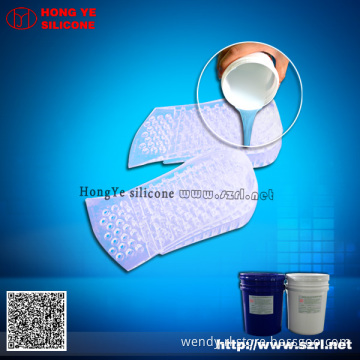

Addition Cure Soft Silicone for Insole Making and Foot Wear as Prosthetic

- Payment Type:

- L/C, T/T, Western Union

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Shenzhen China |

|---|---|

| Payment Type: | L/C, T/T, Western Union |

Product Description

Product Description

Tin Catalyst Silicone for Insole Making

Model number: E608 E610, E620, E625, Q610 Q620, Q625 silicone rubber

Key words: Silicone insole, shoe insole silicone rubber, shoe sole silicone rubber, insole liquid silicone rubber, liquid silicone rubber for insole, shoe insoles silicone rubber

Specifications of Tin Catalyst Silicone for Insole Making

Comfortable and durable Silicone Gel Insole

Ideal for any type of activity sports

Be washable and reusable

Anti-silo heel pads

Provide heel support, extra-cushioning and stability

Protect and prevent impact on the heel bone

Relax foot

More healthy, therapy product

Eco-friendly and environmental-friendly product

Shock-absorption silicone rubber

Description of Addition cure soft silicone for insole making and foot wear as prosthetic:

Tin Catalyst Silicone for Insole Making is a kind of addition cure silicone rubber. It is primarily intended for silicone insole as a kind of foot care silicone rubber. With two component silicone rubber part A and part B, mixing ratio is 1: 1. Generally the color is translucent or transparent.

Datasheet of Addition cure soft silicone for insole making and foot wear as prosthetic:

Storage of Tin Catalyst Silicone for Insole Making

Tin Catalyst Silicone for Insole Making is an environmentally-friendly liquid silicone product, is not easy to burn and can be stored and transported as non-hazardous goods. The shelf life of the product is about 12 months from the date of production. Inspection is required when exceeding the time limited. It can continue to be used in case of neither thickening nor deterioration.

Package of liquid silicone rubber for insole making

5kg/drum, 20kg/drum and 200kg/drum

Shelf-life of addition cure silicone rubber

Twelve (12) months under room temperature 25 Celsius.

Model number: E608 E610, E620, E625, Q610 Q620, Q625 silicone rubber

Key words: Silicone insole, shoe insole silicone rubber, shoe sole silicone rubber, insole liquid silicone rubber, liquid silicone rubber for insole, shoe insoles silicone rubber

Specifications of Tin Catalyst Silicone for Insole Making

Comfortable and durable Silicone Gel Insole

Ideal for any type of activity sports

Be washable and reusable

Anti-silo heel pads

Provide heel support, extra-cushioning and stability

Protect and prevent impact on the heel bone

Relax foot

More healthy, therapy product

Eco-friendly and environmental-friendly product

Shock-absorption silicone rubber

Description of Addition cure soft silicone for insole making and foot wear as prosthetic:

Tin Catalyst Silicone for Insole Making is a kind of addition cure silicone rubber. It is primarily intended for silicone insole as a kind of foot care silicone rubber. With two component silicone rubber part A and part B, mixing ratio is 1: 1. Generally the color is translucent or transparent.

Datasheet of Addition cure soft silicone for insole making and foot wear as prosthetic:

| Model | E608 |

| Appearance | Translucent |

| Mixing proportion of curing agent(%) | 1:1 |

| Operation time(mins) | 20 |

| Shore Hardness (Shore A) | 8 |

| Density (g/cm 3) | 1.08 |

| Viscosity (Mpas-23ºC) | 1000 |

| Mixing viscosity(Mpas-23ºC) | 1100-1200 |

| Tear-strength (kfg/cm ) | 7.0 |

| Tensile-strength (kgf/cm) | 4.2 |

| Elongation-break (%) | 650 |

Storage of Tin Catalyst Silicone for Insole Making

Tin Catalyst Silicone for Insole Making is an environmentally-friendly liquid silicone product, is not easy to burn and can be stored and transported as non-hazardous goods. The shelf life of the product is about 12 months from the date of production. Inspection is required when exceeding the time limited. It can continue to be used in case of neither thickening nor deterioration.

Package of liquid silicone rubber for insole making

5kg/drum, 20kg/drum and 200kg/drum

Shelf-life of addition cure silicone rubber

Twelve (12) months under room temperature 25 Celsius.

Related Keywords

Related Keywords

You May Also Like

You May Also Like