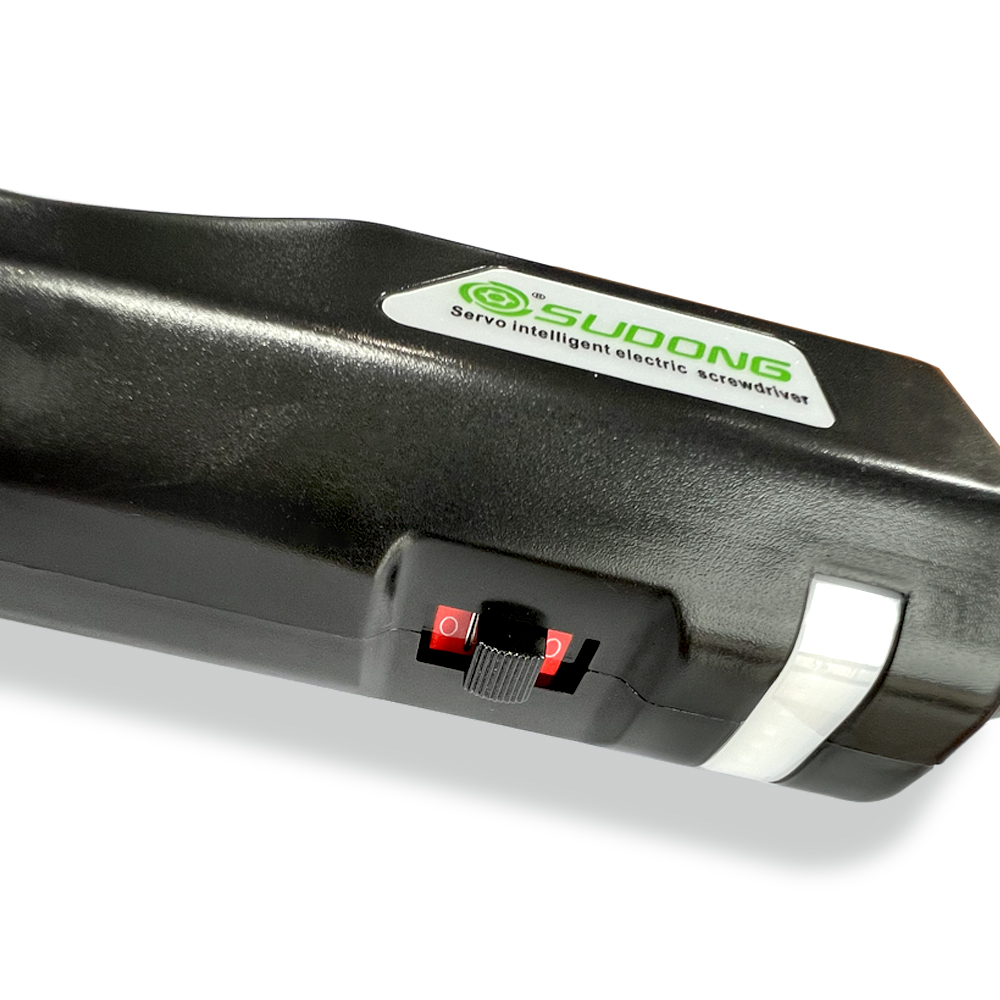

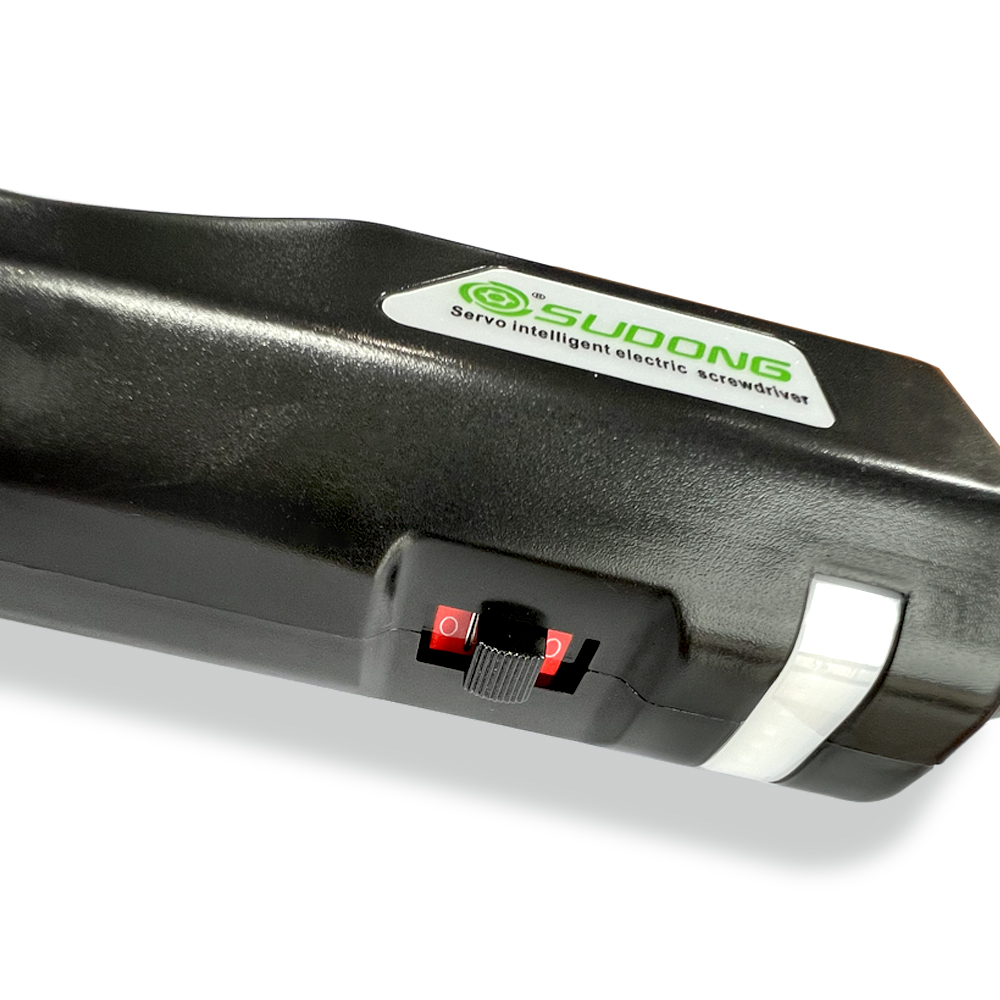

Smart Brushless servo current control torque electric screwdriver SD08L-A

-

$400.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express, Railway

- Port:

- shenzhen

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 1000000 |

| Certificate: | CE,FCC |

| Transportation: | Ocean,Land,Air,Express,Railway |

| Port: | shenzhen |

Product Description

Product Description

-

Features

-

1, Servo Motor

2, Free programming

3, LED prompt light

4, Error prompt

5, Locking paragmeters

6, Easy installation

-

Description

-

SUDONG brushless servo electric screwdriver enables free programming of the screw-tightening process and offer maximal flexibility und process reliability.Within the performance range of each screwdriver, it can freely set and adjust torque, speed, stand-by and rotation direction to achieve precise tightening according to different tightening process requirements.

-

SUDONG brushless servo electric screwdriver is based on servo control technology, which can ensure the torque accuracy control of millions of tightening assemblies within ±5% of the standard deviation.

-

SUDONG brushless servo electric screwdriver is used in applications with high safety requirements (critical screw joints), where a direct measuring system is specified.

-

It can achieve precise control through the bult-in torque and rotative angle trastutionof the ncs screwdrivers during each tightening process and record all important parameters of tightening process in real time

-

Under normal working ,SUDONG brushless servo electric screwdriver can achieve Cmk≥1.67

(torque setting tolerance ±10%),Suitability principle of ISO 5393 and 6Sigma.

1.67 Cmk means only 0.6 failures per million screws,passing rate of 99.99994%.

-

Sudong brushless servo electric screwdriver uses brushless motor with the SD-PF5015/SD-PF5030 controller,Achiving flexibility and reliability in the tightening process.

-

The built-in current and angle measurement enables precise control and monitoring of sudong brushless

servo electric screwdriver in each precise control and monitoring during the tightening process,

enabling the recording of all important tightening process parameters and ensuring the highest accuracy.

-

The use of brushless servo motors significantly reduces operational costs, resulting in long life cycles.

At the same time, it ensures robust power performance and torque bee output, making it the ideal choice

for customers with CNC controlled tight assembly processes.

2, Free programming

3, LED prompt light

4, Error prompt

5, Locking paragmeters

6, Easy installation

(torque setting tolerance ±10%),Suitability principle of ISO 5393 and 6Sigma.

1.67 Cmk means only 0.6 failures per million screws,passing rate of 99.99994%.

servo electric screwdriver in each precise control and monitoring during the tightening process,

enabling the recording of all important tightening process parameters and ensuring the highest accuracy.

At the same time, it ensures robust power performance and torque bee output, making it the ideal choice

for customers with CNC controlled tight assembly processes.

Related Keywords

Related Keywords

You May Also Like

You May Also Like