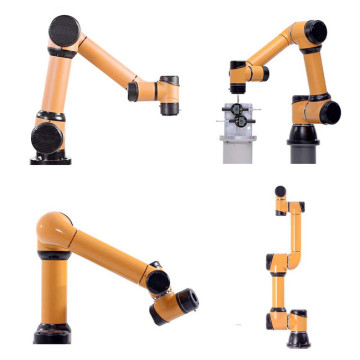

6 axis industrial robot painting machine

- Payment Type:

- L/C, T/T, Paypal, Western Union

- Incoterm:

- FOB, EXW

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 7 Days

- Transportation:

- Ocean, Land

- Port:

- Shenzhen Port

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shenzhen |

|---|---|

| Productivity: | 1000sets/year |

| Supply Ability: | Strong |

| Payment Type: | L/C,T/T,Paypal,Western Union |

| Incoterm: | FOB,EXW |

| Certificate: | CE,CCC,ROHS and ISO9001:2008 |

| Transportation: | Ocean,Land |

| Port: | Shenzhen Port |

6 axis industrial robot painting machine

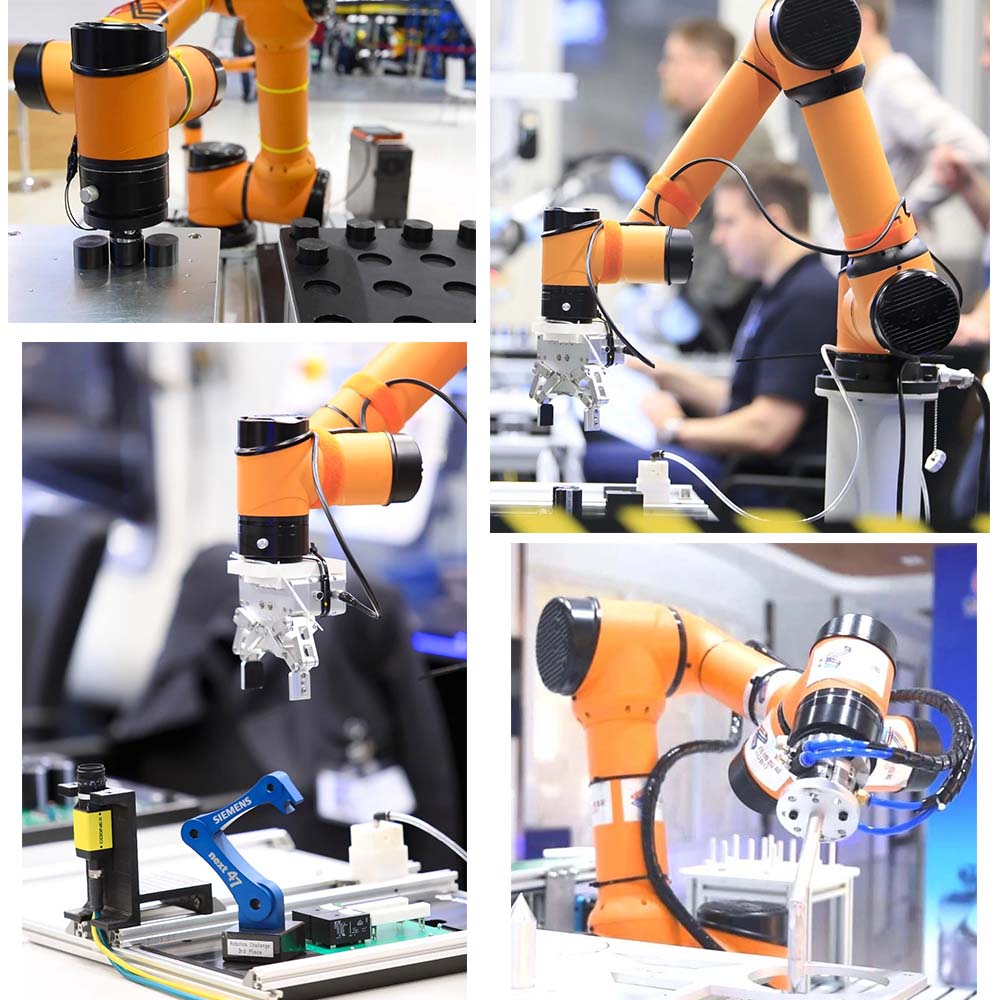

Features of 6 axis industrial robot painting machine: It can improve the automation of the production process; it can improve working conditions and avoid personal accidents; it can reduce manpower and facilitate rhythmic production. Wide application industry, can be used in 35 surface spraying industries, automobiles, furniture, hardware, plastics, wood, toys, glass, ceramics, handicrafts, etc.In addition to the Robot Arm Machine, our company also has many products, such as Soldering Fume Extractor, Solder Paste Dispenser, Pneumatic Hand-held Screw Feeder, Automatic Screw Feeder . If you need these products, you can contact us, we will reply to you as soon as possible.

Safety Functions

1.

Designed in accordance with PLd and ISO 10218-1 (5.10.5 power and force

limiting) safety requirements and compliant with most all

specifications for collaborative robot operation.

2.

Power and force limiting design brings robot to a protective stop if

limits are exceeded or a collision is detected. Speed and force can be

adjusted to fit and optimize any application easily.

3. Sensors imbedded in motor drives provide real-time feedback to prevent dangerous situations.

4. Emergency stop buttons are positioned on teach pendent and control box with a braking distance less than 1mm.

Open Source Architecture

1. CAN bus network used in this robot for multiple microcontrollers to communicate with each other.

2. ROS (Robot Operating System) is supported though API.

3. Hardware adopts CAN bus protocols with open I/O interface extensions.

4. Easily integrate robot into existing production systems.

Return on investment (ROI)

1.

Low cost of ownership, no programming skills needed, and ease of

integration into a system all add up to a quick return on your

investment the average ROI is 3 to 4 months.

2.

Short run, high mix environment job like Lab automation or machine

tending are prime examples of industries needing fast redeployment.

3.

Floor space is a premium cost at most companies usually more than the

equipment. A small foot print, light weight robot will be a huge benefit

for any size companies cost of production.

4.

Repurpose, redeploy and or reinvent applications with the same robot,

change the number of degrees of freedom, joints and tubes are modular

making it easy to repair as well as reconfigure.

Technical Specifications

| Controlled Axed DoF | 6 axes (J1, J2, J3, J4, J5, J6) J7max |

| Reach | 924 mm |

| Working Range | 880 mm |

| Payload | 5kg |

| Weight | 24kg |

| Footprint | 172 mm diameter |

| Collabortative Operation |

Safety-rated monitored stop, and guiding, speed and separation monitoring, power and force limiting |

| Certifications | ISO 10218-1:2011, EN 60204-1:2006 +A1:2009 |

| ISO 12100:2010, ISO 13849-1:2008, CE | |

| Repeatability | ±0.02mm |

| Linear Velocity | 2.8 m/s adjustable |

| Power Consumption | 200 watts typical application |

| Materials | Aluminum, Steel, Plastic |

| Ambient Humidity | Normal 75% RH or less without frost, or dew, 85% RH short term |

| Ambient Temperature | 0 to 45 degrees Celsius |

| IP Classification of Robot | IP 54 |

| Programing |

Teach Pendant with user interface, guide to teach, ROS compatibility through an API, Lua, Python |

| Communication | CAN Bus |

| Motor Type | Harmonic drive 48 Volt |

| Installation Orientation | Any celling, Floor, Wall |

| Axis | Working Range | MAximun Speed | Max Joint Moments |

| J1 axis rotation base | (+/-)175° | 150°/sec | 207Nm |

| J2 axis rotation shoulder | (+/-)175° | 150°/sec | 207Nm |

| J3 axis rotation elbow | (+/-)175° | 150°/sec | 207Nm |

| J4 axis wrist rotation | (+/-)175° | 180°/sec | 34Nm |

| J5 axis wrist swing | (+/-)175° | 180°/sec | 34Nm |

| J6 axis wrist rotation | (+/-)175° | 180°/sec | 34Nm |

Control Box

| Dimensions (LxWxH) | 683x220x622 mm | I/O Ports | GENERAL I/O | ||

| Weight | 20kg | Digital in | 16 | 16 | |

| Cabling | 5m | Digital Out | 16 | 16 | |

| Colour | Black | Analog in | 4 | ||

| Communication | TCP/IP, Modbus-RTU/TCP | ||||

| Power supply | 100-240 VAC, 50-60Hz | ||||

| IP Classification | IP54 |

| I/O PORTS | GENERAL I/O | SAFETY I/O |

| Digital in | 16 | 16 |

| Digital Out | 16 | 16 |

| Analog in | 4 |

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Well-trained and experienced staffs to answer all your inquiries in fluent English

3. OEM&ODM

4. Good quality paper box & carton packing

5. Double check before shipping

6. Safely Shipping method,such as DHL /EMS /FEDEX/TNT /UPS

7. Ocean Freight or cargo forwarder service

8. Sample order in small quantity is acceptable

For more detailed information or catalog, please kindly contact us!

Related Keywords