Robotic Arm Pouring Forging Manipulator

- Payment Type:

- L/C, T/T, Paypal, Western Union

- Incoterm:

- FOB, EXW

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 7 Days

- Transportation:

- Ocean

- Port:

- Shenzhen Port

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shenzhen |

|---|---|

| Productivity: | 10000sets/year |

| Supply Ability: | Strong |

| Payment Type: | L/C,T/T,Paypal,Western Union |

| Incoterm: | FOB,EXW |

| Certificate: | CE,CCC,ROHS and ISO9001:2008 |

| Transportation: | Ocean |

| Port: | Shenzhen Port |

Robotic Arm Pouring Forging Manipulator

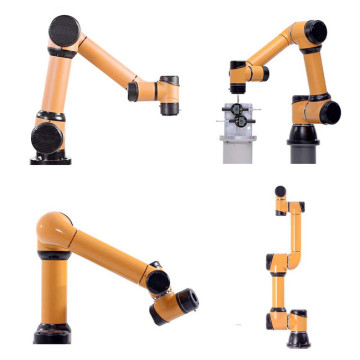

The forging manipulator is composed of three parts: the execution system, the drive system and the control system.

The executive system generally consists of hands, wrists, arms, body, and some additional walking mechanisms. The drive system is composed of drive elements and transmission mechanisms. There are four commonly used forms: hydraulic transmission, pneumatic transmission, electronic transmission and mechanical transmission. The control system consists of a control device and a detection device. Generally, electrical control is used, which governs the movement of the manipulator according to a prescribed program, and monitors the movement of the manipulator when necessary. When there is an error or fault in the action, it can be fed back to the control system for adjustment or an alarm signal.

Intelligence

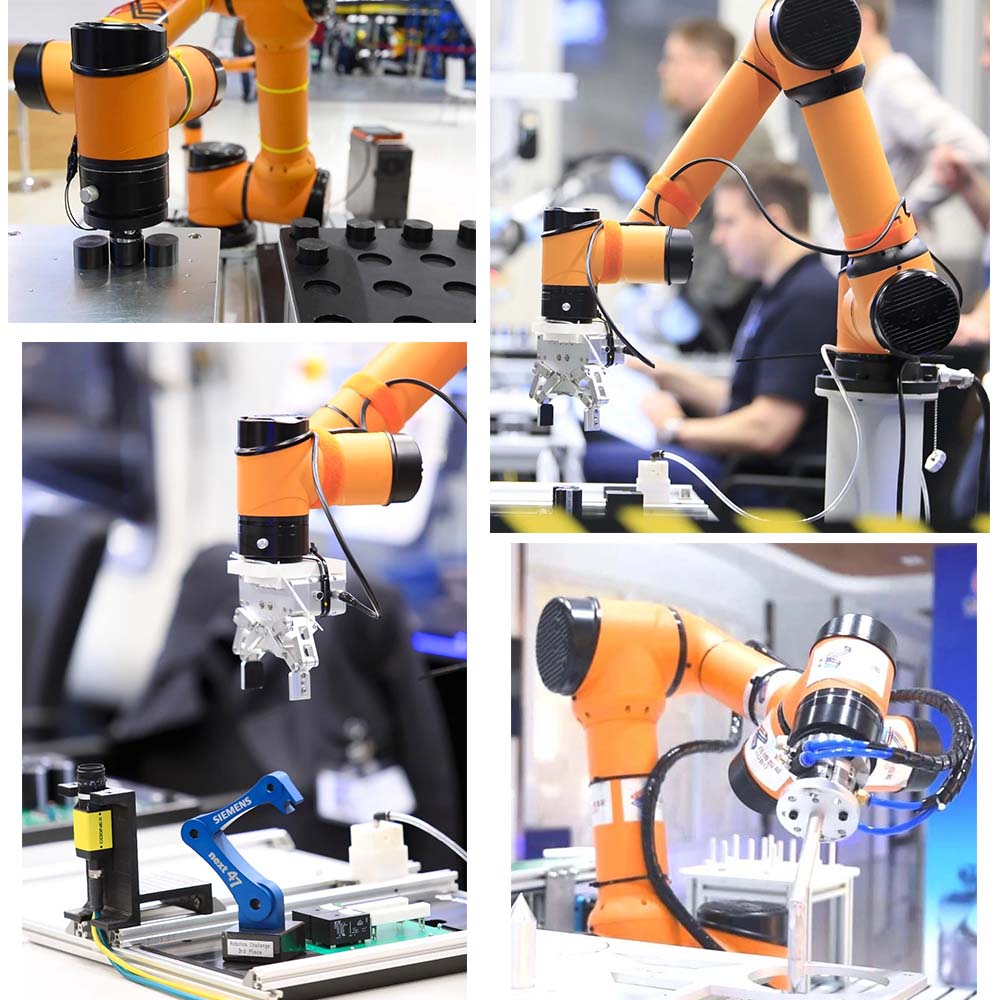

1. Vision systems can be integrated into controller.

2. Software system based on cloud platform management that realizes remote maintenance, fault diagnosis and online upgrading of firmware.

3. This research robot platform is used widely around the world in corporate research labs and for academic robotics research.

Modular Design

1. Robot can be configured to have between four and seven degrees of freedom to meet user requirement.

2. Joint length can be customized to longer or shorter links.

In addition to the Robot Arm Machine, our company also has many products, such as Soldering Fume Extractor, Solder Paste Dispenser, Pneumatic Hand-held Screw Feeder, Automatic Screw Feeder . If you need these products, you can contact us, we will reply to you as soon as possible.

Technical Specifications

| Controlled Axed DoF | 6 axes (J1, J2, J3, J4, J5, J6) J7max |

| Reach | 924 mm |

| Working Range | 880 mm |

| Payload | 5kg |

| Weight | 24kg |

| Footprint | 172 mm diameter |

| Collabortative Operation |

Safety monitored stop, speed and separation monitoring, hand guid operation, power and force limiting design. |

| Certifications |

ISO 10218-1:2011, EN 60204-1:2006 +A1:2009 ISO 12100:2010, ISO 13849-1:2008, CE |

| Repeatability | ±0.02mm |

| Linear Velocity | 2.8 m/s adjustable |

| Power Consumption | 200 watts typical application |

| Materials | Aluminum, Steel, Plastic |

| Ambient Humidity | Normal 75% RH or less without frost, or dew, 85% RH short term |

| Ambient Temperature | 0 to 45 degrees Celsius |

| IP Classification of Robot | IP 54 |

| Programing |

Teach Pendant with user interface, guide to teach, ROS compatibility through an API, Lua, Python. |

| Communication | CAN Bus |

| Motor Type | Harmonic drive 48 Volt |

| Installation Orientation | Any celling, Floor, Wall |

| Axis | Working Range | MAximun Speed | Max Joint Moments |

| J1 axis rotation base | (+/-)175° | 150°/sec | 207Nm |

| J2 axis rotation shoulder | (+/-)175° | 150°/sec | 207Nm |

| J3 axis rotation elbow | (+/-)175° | 150°/sec | 207Nm |

| J4 axis wrist rotation | (+/-)175° | 180°/sec | 34Nm |

| J5 axis wrist swing | (+/-)175° | 180°/sec | 34Nm |

| J6 axis wrist rotation | (+/-)175° | 180°/sec | 34Nm |

| Dimensions (LxWxH) | 683x220x622 mm | I/O Ports | User I/O | Safety I/O | |

| Weight | 20kg | Digital in | 16 | 16 | |

| Cabling | 5m | Digital Out | 16 | 16 | |

| Colour | Black | Analog in | 4 | - | |

| Communication | TCP/IP, Modbus-RTU/TCP | Analog out | 4 | - | |

| Power supply | 100-240 VAC, 50-60Hz | Power input | 24 Volts | ||

| IP Classification | IP54 | Power output | 3A | ||

Related Keywords