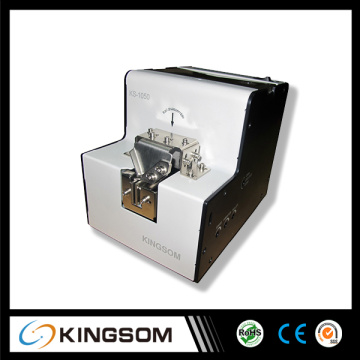

Nejicco Sas-503 Series Automatic Screw Feeder

- Payment Type:

- L/C, T/T, Paypal, Western Union

- Incoterm:

- FOB, EXW

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 5 Days

- Transportation:

- Ocean, Land

- Port:

- Shenzhen Port

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000sets/day |

| Supply Ability: | Strong |

| Payment Type: | L/C,T/T,Paypal,Western Union |

| Incoterm: | FOB,EXW |

| Certificate: | CE,CCC,ROHS and ISO9001:2008 |

| Transportation: | Ocean,Land |

| Port: | Shenzhen Port |

Nejicco Sas-503 Series Automatic Screw Feeder's functions: automatic screw alignment, feeding, automatic screening of special-shaped screws, and automatic replenishment of empty material. Without taking the screw by hand, the screw feeds automatically, freeing the left hand and allowing you to pick and place products. The efficiency is as high as 60 capsules per minute, as fast as you can lock. Strong versatility, hand-held screwdriver, flexible operation, suitable for fixed-point operation. The electric screwdriver cover is light and handy, and the torque adjustment is precise and convenient, ensuring the locking quality. The shape is small and compact, and the conveying distance can reach 4 meters. The machine can be placed on the worktable to save space.

In addition to the Handheld Auto Screw Feeder, our company also has many products, such as Soldering Fume Extractor, Solder Paste Dispenser, Pneumatic Hand-held Screw Feeder,Extruder Screw Feeder and Robot Arm Machine. If you need these products, you can contact us, we will reply to you as soon as possible

Performance

1. Lets your assemblers pick up and drive screws faster than hand feeding or shaker box methods.

2. Each unit is fully automatic;

3. Operators dump loose screws into hopper, dipper scoops them out, aligning them "heads up" in the feeder rail.

4. Operator then simply presses the magnetized bit of a screwdriver into the bit guide and snaps up a screw.

5. The fastening motion is completed in just a second or two.

6. "Autocatcher" or vacuum pick-up attachment can also be used to chuck the screw.

7. These screw feeders are lightweight (1.1Kg.), easy to move, and require little space on work tables or assembly lines.

8. These units are small enough that several feeders can be used at a single work station for quick pick-up of different screw types and sizes. Features built-in vibratory systems.

Related Keywords