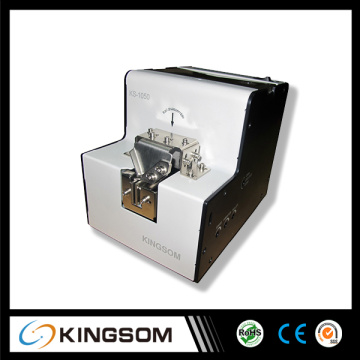

Nejicco Sas-503 Series Screw Feeder Equipment

- Payment Type:

- L/C, Paypal, Western Union

- Incoterm:

- FOB, EXW

- Delivery Time:

- 7 Days

- Transportation:

- Ocean, Land

- Port:

- Shenzhen Port

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000sets/day |

| Supply Ability: | Strong |

| Payment Type: | L/C,Paypal,Western Union |

| Incoterm: | FOB,EXW |

| Certificate: | CE,CCC,ROHS and ISO9001:2008 |

| Transportation: | Ocean,Land |

| Port: | Shenzhen Port |

NEJICCO Screw Feeder SAS-503 Series

How to choose a good automatic screwing machine? The first step is to check whether it can be screened: there may be flashing, flat head, big head and other special-shaped screws in the actual production. Screw inside the hopper. If the screw machine can automatically screen out the special-shaped screws during the operation, the card machine will not appear, that is, one of the conditions for a good screw machine is satisfied. The second step is to check whether replenishment is possible: when we take the first step, after the screw machine automatically selects a special-shaped screw, there must be a gap; if the system can supply in time, there will be no gap Yes. This is the second condition for a good screw machine.

Performance

1. Lets your assemblers pick up and drive screws faster than hand feeding or shaker box methods.

2. Each unit is fully automatic;

3. Operators dump loose screws into hopper, dipper scoops them out, aligning them "heads up" in the feeder rail.

4. Operator then simply presses the magnetized bit of a screwdriver into the bit guide and snaps up a screw.

5. The fastening motion is completed in just a second or two.

6. "Autocatcher" or vacuum pick-up attachment can also be used to chuck the screw.

7. These screw feeders are lightweight (1.1Kg.), easy to move, and require little space on work tables or assembly lines.

8. These units are small enough that several feeders can be used at a single work station for quick pick-up of different screw types and sizes. Features built-in vibratory system.

1. Your inquiry related to our products or prices will be replied in 24 hours.

2. Well-trained and experienced staffs to answer all your inquiries in fluent English

3. OEM&ODM

4. Good quality paper box & carton packing

5. Double check before shipping

6. Safely Shipping method,such as DHL /EMS /FEDEX/TNT /UPS

7. Ocean Freight or cargo forwarder service

8. Sample order in small quantity is acceptable

For more detailed information or catalog, please kindly contact us!

Related Keywords