Portable automatic torque adjustable electric screwdriver

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB, EXW

- Min. Order:

- 100 Piece/Pieces

- Min. Order:

- 100 Piece/Pieces

- Delivery Time:

- 7 Days

- Transportation:

- Ocean, Air

- Port:

- Shenzhen Port

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shenzhen |

|---|---|

| Productivity: | 10000sets/year |

| Supply Ability: | 10000set/year |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,EXW |

| Certificate: | CE,CCC,ROHS and ISO9001:2008 |

| Transportation: | Ocean,Air |

| Port: | Shenzhen Port |

Portable automatic torque adjustable electric screwdriver

Use method of pointer torque screwdriver:

1. Adjust pointer to zero

Try it several times according to the method used, then loosen the positioning long bolt, let the black pointer point to zero, and tighten the positioning long bolt.Pointer torque drivers can be used in both directions.However, with each change of direction, zero must be readjusted.

2. Use red and black Pointers together

The black pointer is the active pointer, and the red pointer is the bottom pointer.When used, the red pointer can be followed by the black pointer pointing to zero at the same time, and then the torque driver can be rotated for testing.Once the spinning stops, the black pointer will automatically return to zero, while the red pointer will stay at the position of the maximum value just reached, playing the role of leaving the bottom.When used again, reposition the red pin to zero.

3. Change of knife head

The head of the pointer type torque driver is the general 6.3 hexagonal hole, which can be easily replaced with "-", "+" or other shapes of tool heads.

In addition to Automatic Electric Screwdriver, our company also has Built-In Counter Electrical Screwdriver Sets, Infrared Induction Screwdriver Electric,Cell Phone Repair Kit,Servo Electric Screwdriver and Mobile Electric Screwdriver,Hand Tool High Electric Screwdriver.

|

Servo Motor Series |

Intelligent Counter Series |

Built-in Counter Series |

Economical Series |

|

Super Value Series |

Screw Feeder |

Screwdriving Machine |

Robot Arm |

Programming Free

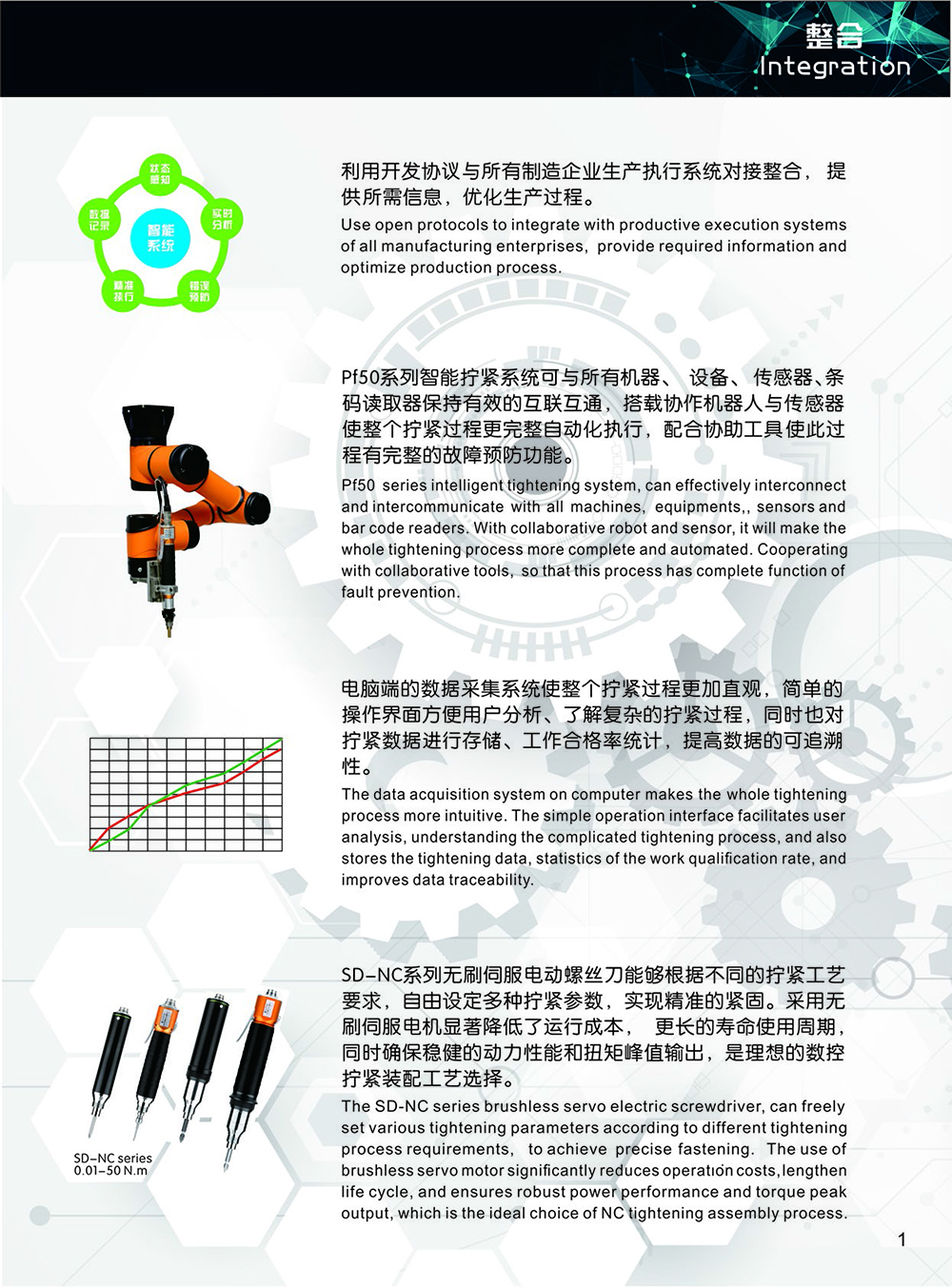

Sudong brushless servo electric screwdriver can realize free programming of the tightening assembly process.

Within the performance parameters, it can realize precise fastening, according to different tightening process requirements to set freely, adjustable torque, speed, waiting time and direction of rotation.

Precise Control and Monitoring

Built-in current and rotative angle sensor can realize precise control and monitoring of Sudong brushless servo electric screwdrivers during each tightening process, record all important parameters of tightening process, and ensure the highest accuracy

Brushless Servo Motor

- Reduce the running costs, long life usage.

- The torque accuracy of screw tightening torque can be controlled within 3% of standard deviation.

- Cmk > 1.67 (torque setting tolerance +-10%), complying with ISO 5393 and 6 Sigma principles, that means only 0.6 failure rate per million screws and 99.99994% qualified rate.

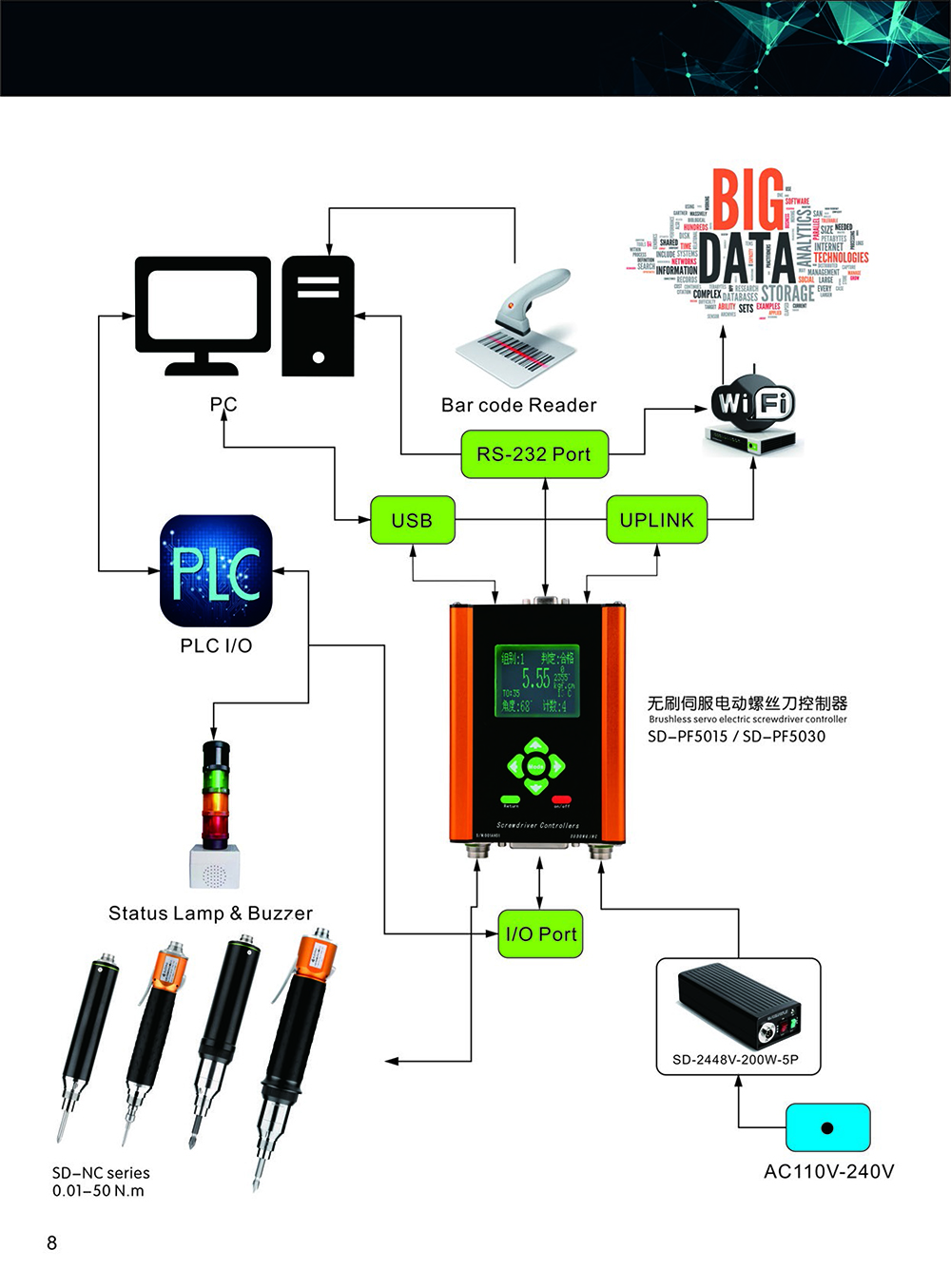

- Supplied with SD-PF5015 or SD-PF5030 controller.

Performance of the controller

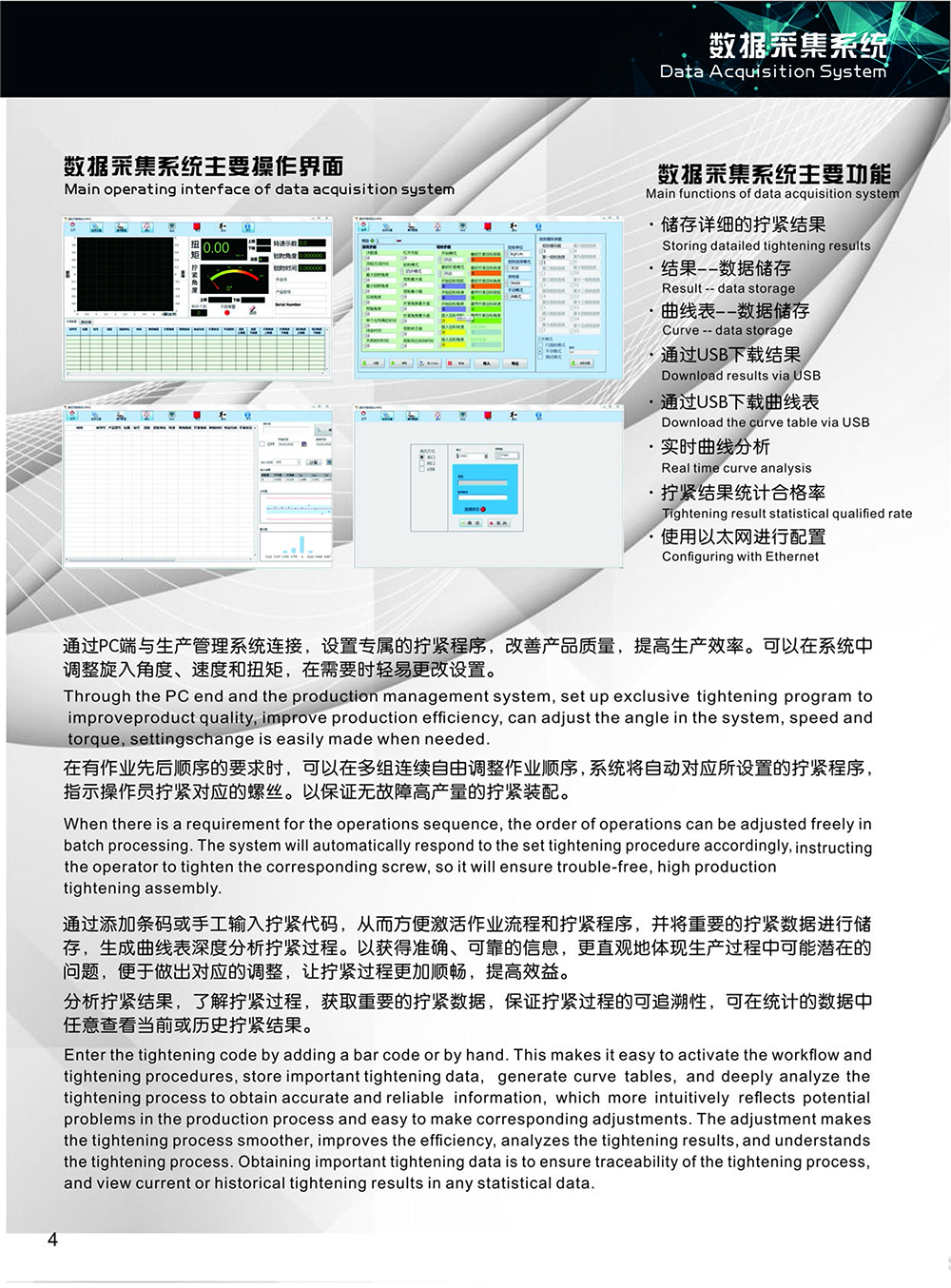

1- Can support maximum 20 groups of different parameters for cycling use.

2- Single set of data reach up to 24 kinds of parameters to choose settings.

3- Tightening status display and tightening process monitoring.

4- Tightening torque and speed real-time display.

5- Connect to the PC or automation device in a variety of ways.

6- A single electric screwdriver can also set multiple tightening parameters.

7- Work piece tightening historical data storage, statistical work qualified rate.

8- Multiple groups of tightening data storage, output.

1. Your inquiry related to our products or prices will be replied in 24 hours.

2. Well-trained and experienced staffs to answer all your inquiries in fluent English

3. OEM&ODM

4. Good quality paper box & carton packing

5. Double check before shipping

6. Safely Shipping method,such as DHL /EMS /FEDEX/TNT /UPS

7. Ocean Freight or cargo forwarder service

8. Sample order in small quantity is acceptable

For more detailed information or catalog, please kindly contact us!

Related Keywords