Zinc and Aluminium Die Casting Component

- Payment Type:

- T/T, Western Union, Paypal

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Shenzhen, China |

|---|---|

| Payment Type: | T/T, Western Union, Paypal |

Product Description

Product Description

XY-Global has been serving the global market since 2005. The company headquarter is located in Shenzhen, China with two main offices in USA and in Israel.

We develop and manufacture CNC Machining parts, Die-casting Parts, Stamping Parts, Punching parts and Plastic injection parts. These parts are used for telcommunication and medical, and computer, and networking.

Our main customer are in USA, Israel, Chile, Greece, Spain, Middle East and many others. Such as EXTRONICS, Samsung, LG, OBI, ASUS, FUJITSU, ECI, AIRSPAN, SURF and so on.

XY-Global is a professional in Zinc and Aluminium die casting parts manufacturer, We have been in this trade for more than 8 years.

Specifications

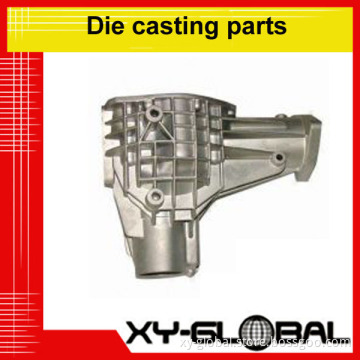

Die casting, aluminum die casting parts, zinc die casting part; Competitive price; Quality assurance; Prompt delivery.

Description: Die casting parts, aluminum die casting, zinc die casting parts.

We are s a professional Zinc and Aluminium die casting parts manufacturer, we have been in this trade for more than 8 years.

OEM / ODM parts range: Aluminum die-casting, Zinc die-casting, Die-casting mould, Die cast part, Auto parts, LED lighting parts, Aluminum heat sink, Industrial hardware components, Zinc alloy die-casting, Bathroom accessories, Machinery parts.

· Aluminum/Zinc die casting auto part

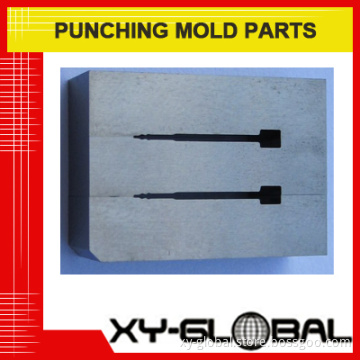

· Die casting mold

· Cavity: Single

· Mold materials: H13, DIEVAR, QDN, 8407, 2344V, TQ1, 2343 and SKD61

· Mold heat treatment: Hardened and nitriding

· Mold hardness: HRC50 to 55

· Mold features:

Advanced design

Logical structure

High precision

Qualified materials

Long lifetime

Short delivery time

Die casting product

Die casting materials: Aluminum alloy, A360, A380, A383, AlSi10Mg, AlSi9Cu3, ADC3, ADC6, ADC12, ZL104 and ZL107

· Process: Casting, deburring, machining, surface treatment and packing

· Surface treatments: High quality polishing, chrome/nickel/zinc (white, blue, yellow, black) plating, hot galvanized, painting, powder coating, anodizing, electrophoresis and sandblasting

· Lead time: 30 to 40 days

· Software: PRO/E, AutoCAD, SolidWork, CAXA, CAD and CAM

· Machines: High-speed processing center, walking thread cuttings, precision machine sparks, large grinding machines, CNC engraving machines and 10 pieces of die-casting machines (range from 160 to 1250T)

· Inspection equipment: Metal material metallographic analyzer, metal detection machine, coordinate measuring machine, large-scale aluminum material direct reading spectrometer and tensile testing machine

We develop and manufacture CNC Machining parts, Die-casting Parts, Stamping Parts, Punching parts and Plastic injection parts. These parts are used for telcommunication and medical, and computer, and networking.

Our main customer are in USA, Israel, Chile, Greece, Spain, Middle East and many others. Such as EXTRONICS, Samsung, LG, OBI, ASUS, FUJITSU, ECI, AIRSPAN, SURF and so on.

XY-Global is a professional in Zinc and Aluminium die casting parts manufacturer, We have been in this trade for more than 8 years.

Specifications

Die casting, aluminum die casting parts, zinc die casting part; Competitive price; Quality assurance; Prompt delivery.

Description: Die casting parts, aluminum die casting, zinc die casting parts.

We are s a professional Zinc and Aluminium die casting parts manufacturer, we have been in this trade for more than 8 years.

OEM / ODM parts range: Aluminum die-casting, Zinc die-casting, Die-casting mould, Die cast part, Auto parts, LED lighting parts, Aluminum heat sink, Industrial hardware components, Zinc alloy die-casting, Bathroom accessories, Machinery parts.

· Aluminum/Zinc die casting auto part

· Die casting mold

· Cavity: Single

· Mold materials: H13, DIEVAR, QDN, 8407, 2344V, TQ1, 2343 and SKD61

· Mold heat treatment: Hardened and nitriding

· Mold hardness: HRC50 to 55

· Mold features:

Advanced design

Logical structure

High precision

Qualified materials

Long lifetime

Short delivery time

Die casting product

Die casting materials: Aluminum alloy, A360, A380, A383, AlSi10Mg, AlSi9Cu3, ADC3, ADC6, ADC12, ZL104 and ZL107

· Process: Casting, deburring, machining, surface treatment and packing

· Surface treatments: High quality polishing, chrome/nickel/zinc (white, blue, yellow, black) plating, hot galvanized, painting, powder coating, anodizing, electrophoresis and sandblasting

· Lead time: 30 to 40 days

· Software: PRO/E, AutoCAD, SolidWork, CAXA, CAD and CAM

· Machines: High-speed processing center, walking thread cuttings, precision machine sparks, large grinding machines, CNC engraving machines and 10 pieces of die-casting machines (range from 160 to 1250T)

· Inspection equipment: Metal material metallographic analyzer, metal detection machine, coordinate measuring machine, large-scale aluminum material direct reading spectrometer and tensile testing machine

Related Keywords

Related Keywords