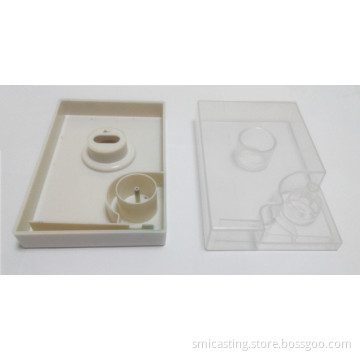

Plastic Injection Mold J-008

- Payment Type:

- L/C, T/T, D/P, Paypal

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Shenzhen China |

|---|---|

| Payment Type: | L/C, T/T, D/P, Paypal |

Product Description

Product Description

Export Markets: Global

Additional Info.

Packing: Standard Export Wooden Box

Standard: As Per Customers Requirement

Origin: China

HS Code: 8480710090

Production Capacity: 60 sets/Month

Product Description

Plastic Injection Mold

1. Mould steel: Steel 45#, 50#, 718, 2083, P20, NAK80, etc.

2. Plastic Material: ABS, PP, PE or as per customer requirement

3. Mould life: 500, 000 shots or as per customer requirement

4. Product Size: As per customer requirement

5. Runner: Hot/cold

6. Cavity: Single/multi

7. Design software: UG, PROE, PROWERMILL, CAD, CAXA ect

8. Advanced CNC machining centers, EDM machine, wiring machine, grinding machines, lathes, drilling, injection molding machines, and other large and medium-sized imported equipment alike.

Manufacturing Processes:

Step 1: Mapping and Surveying

Step 2: 2D&3D date drawing

Step 3: Machining( CNC, Drilling, Milling, EDM, WDEM, Engraving and Die Spotting)

Step 4: Assembly

Step 5: Mold Trial

Step 6: Mold Modification

We have a lot of experience in making plastic mould(injection mould), such as auto part mould, household appliance mould, ATV mould, daily necessity mould, turnover box mould, plastic crate mould, plastic pallet mould, and we can also manufacture finished product.

Additional Info.

Packing: Standard Export Wooden Box

Standard: As Per Customers Requirement

Origin: China

HS Code: 8480710090

Production Capacity: 60 sets/Month

Product Description

Plastic Injection Mold

1. Mould steel: Steel 45#, 50#, 718, 2083, P20, NAK80, etc.

2. Plastic Material: ABS, PP, PE or as per customer requirement

3. Mould life: 500, 000 shots or as per customer requirement

4. Product Size: As per customer requirement

5. Runner: Hot/cold

6. Cavity: Single/multi

7. Design software: UG, PROE, PROWERMILL, CAD, CAXA ect

8. Advanced CNC machining centers, EDM machine, wiring machine, grinding machines, lathes, drilling, injection molding machines, and other large and medium-sized imported equipment alike.

Manufacturing Processes:

Step 1: Mapping and Surveying

Step 2: 2D&3D date drawing

Step 3: Machining( CNC, Drilling, Milling, EDM, WDEM, Engraving and Die Spotting)

Step 4: Assembly

Step 5: Mold Trial

Step 6: Mold Modification

We have a lot of experience in making plastic mould(injection mould), such as auto part mould, household appliance mould, ATV mould, daily necessity mould, turnover box mould, plastic crate mould, plastic pallet mould, and we can also manufacture finished product.

Related Keywords

Related Keywords