Liquid Molding silicone rubber/(RTV) silicone rubber

- Payment Type:

- T/T, D/A

- Incoterm:

- FOB

- Min. Order:

- 200 Kilogram

- Min. Order:

- 200 Kilogram

- Delivery Time:

- 3 Days

- Transportation:

- Ocean, Air

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 8000kg/day |

| Supply Ability: | 8000kg/day |

| Payment Type: | T/T,D/A |

| Incoterm: | FOB |

| Transportation: | Ocean,Air |

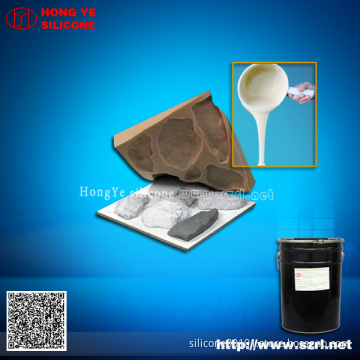

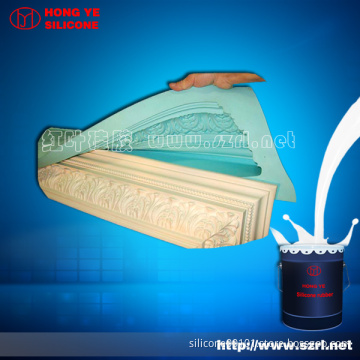

Liquid Molding silicone rubber/(RTV) silicone rubber application

liquid molding silicone rubber is suitable for industries such as toys, gifts, furniture decoration, construction decoration, stationery, resin crafts, unsaturated resin crafts, poly resin crafts, candle crafts, plastic crafts, plastercrafts, artificial plant and animal crafts, Buddhist statue crafts.

Liquid molding silicone rubber/ (RTV) silicone rubber features

a) Good characteristics of easy-operation

b) Good flowability and light viscosity

c) Low shrinkage

d) No deformation

e) Favorable tension

f) Favorable hardness

g) High temperature resistance, acid and alkali-resistance and aging resistance

Liquid molding silicone rubber/ (RTV) silicone rubber description

Tin-based silicones, also called condensation-cure silicones, are two-component materials which cure at room temperature(RTV)to flexible, high tear-strength rubbers. Tin cured silicones can be poured onto models or they can be made brushable by adding a thixotropic additive. They are ideal for molds where easy release or high temperature resistance is required. Tin cured silicones can be used for casting polyurethane, epoxy and polyester resins, waxes, all gypsum products and low-temperature metals. Our tin-cured silicone systems are the most economical. They are best used for casting resins and low melt metals.

Liquid molding silicone rubber/ (RTV) silicone rubber instruction

During operate the three important thing to pay attention

1. weigh theliquid silicone rubber and curing agent exatly

2. Stir theliquid silcone rubber and curing agent evenly

3.we shouldchoose the right hardness to making diffirent size of product mold

Liquid molding silicone rubber/ (RTV) silicone rubber Datasheet

|

Model |

635# |

|

Appearance |

white |

|

Mixing proportion of curing agent (%) |

3% |

|

Operating time (mins 25 0C ) |

30-45 |

|

Curing time(hours 25 0C) |

6-8 |

|

Hardness (A) |

352 |

|

Density ( g/cm3) |

1.08 |

|

Viscosity (mPas -25 0C) |

280003000 |

|

Tensile-strength(kgf /cm2) |

49 |

|

Tear-strength (kgf /cm) |

27 |

|

Elongation-break(%) |

530 |

More information about the silicone rubber, pls contact Ms Penny:

Tel: +86-0755-89948019

Mob: +86-18938867520

Fax: +86-0755-89948030

Email: silicone0010 at gmail dot com

Related Keywords