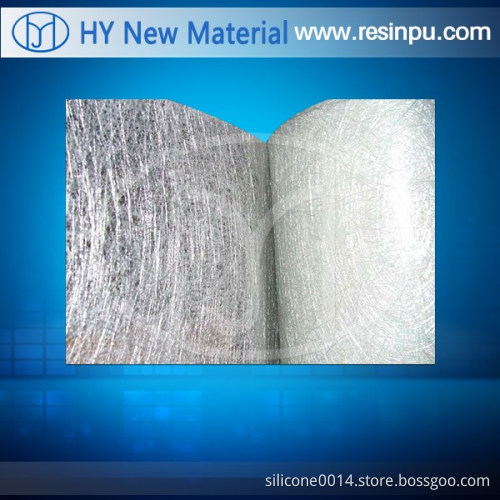

Glass Fiber Chopped Strand Mat

- Payment Type:

- T/T, L/C, Western Union

- Incoterm:

- FOB

- Min. Order:

- 200 Kilometer

- Min. Order:

- 200 Kilometer

- Delivery Time:

- 5 Days

- Transportation:

- Ocean

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | china |

|---|---|

| Productivity: | 8ton/day |

| Supply Ability: | 8ton/day |

| Payment Type: | T/T,L/C,Western Union |

| Incoterm: | FOB |

| Certificate: | ISO 9000/9001/9004/19011: 2000 |

| Transportation: | Ocean |

Glass Fiber Chopped Strand Mat Description

E-Glass Fiber chopped strand mat is a kind of non-woven glass fiber reinforced material, which is made by chopping glass fiber first, then be settled down non-directional and uniform, adding some powder or emulsion binder. It is mainly used for hand laying up process and laminating process, easy to process, with excellent forming performance. Chopped strand mat can be saturated with resin fast, with high transparency, at the same time, uniform fiber makes the products smooth on surface during the lamination process, good performance on coating model.

Glass Fiber Chopped Strand Mat Characteristics

1)Weight is evenly distributed per gram

2)Saturated fast,

3)Bubbles easy to be eliminated,

4)High transparency

5)Excellent coating model performance

6)Less consumption of resin.

Glass Fiber Chopped Strand Mat Application

Mainly used for tank, winding pipe products, the surface layer of the glass products. Can improve the surface corrosion resistance and enhance the compressive strength for finished fiber glass products, prevent leakage, prolong the service life.

Hand laying up type glass fiber mat is mainly used for hand laying up product with complex geometric curve, it is with excellent coating model performance, rapid resin saturated speed, can improve the strength and corrosion resistance performance for finished glass fiber mat products.

Glass Fiber Chopped Strand Mat Technical Parameters

|

Model |

Type |

Mass per Unite Area(g/m2) |

Width(mm) |

Linear density(μm) |

Loss on lgnition(%) |

|

WDQ150 |

E-Glass |

150 |

1040 |

11-13 |

1.5%-8.5% |

|

WDQ225 |

E-Glass |

225 |

1040 |

11-13 |

1.5%-8.5% |

|

WDQ280 |

E-Glass |

280 |

1040 |

11-13 |

1.5%-8.5% |

|

WDQ300 |

E-Glass |

300 |

1040 |

11-13 |

1.5%-8.5% |

|

WDQ450 |

E-Glass |

450 |

1040 |

11-13 |

1.5%-8.5% |

|

ZDQ280 |

C-Glass |

280 |

1040 |

13-17 |

3.0%-6.0% |

|

FDQ300 |

CP-Glass |

300 |

1040 |

13-17 |

3.0%-6.0% |

Glass Fiber Chopped Strand Mat Packaging

|

Packing |

Quantity |

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Plastic Film+ Carton Box+Pallet |

About 10tons/ 20 ft 23tons/ 40ft Glass Fiber Chopped Strand Mat DescriptionE-Glass Fiber chopped strand mat is a kind of non-woven glass fiber reinforced material, which is made by chopping glass fiber first, then be settled down non-directional and uniform, adding some powder or emulsion binder. It is mainly used for hand laying up process and laminating process, easy to process, with excellent forming performance. Chopped strand mat can be saturated with resin fast, with high transparency, at the same time, uniform fiber makes the products smooth on surface during the lamination process, good performance on coating model.

Glass Fiber Chopped Strand Mat Characteristics1)Weight is evenly distributed per gram2)Saturated fast,3)Bubbles easy to be eliminated,4)High transparency5)Excellent coating model performance6)Less consumption of resin.

Glass Fiber Chopped Strand Mat ApplicationMainly used for tank, winding pipe products, the surface layer of the glass products. Can improve the surface corrosion resistance and enhance the compressive strength for finished fiber glass products, prevent leakage, prolong the service life. Hand laying up type glass fiber mat is mainly used for hand laying up product with complex geometric curve, it is with excellent coating model performance, rapid resin saturated speed, can improve the strength and corrosion resistance performance for finished glass fiber mat products.

Glass Fiber Chopped Strand Mat Technical Parameters

Glass Fiber Chopped Strand Mat Packaging

|

Related Keywords