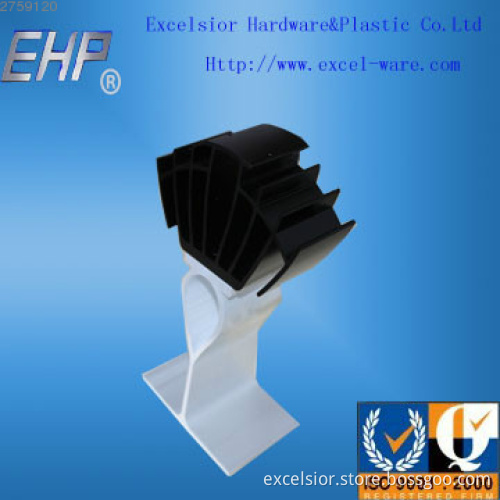

Basic Specification

| Finishing | BlackAnodizing |

|---|---|

| Dimension | Customized |

| Application | ECO Fan |

| Material | Aluminum |

| Micro Machining | Yes |

| Type | Milling |

| CNC Machining | Yes |

Detail Description

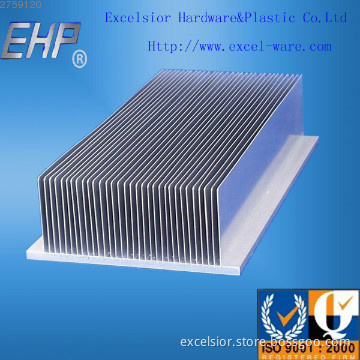

heat sink, aluminum heat sink/exchanger

Special Offer

Excelsior Hardware&Plastic Co., Ltd. is a well established company with 6 years experience in aluminum alloy heat sink and plastic mould design. We are specialised in the design,and fabricate extrusion heat sink, Aluminum Extrusion,Sheet Metal Enclosure, and Metal Parts incorporating a variety of materials and finishes. We offerer a full service for the commissioning of your project, from concept design to installation and maintaince. Our design service includes the supply of CAD drawings for client approval before the fabrication process commences. Alternatively, we can provide a fabrication and installation service from existing drawings

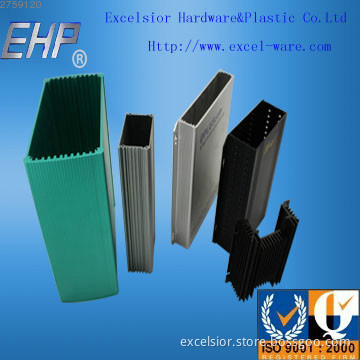

aluminum alloy heat sink Features

1)Equipment: We own Stamping machines, Hydraulic press machines, Auto-Turning machines, CNC-Turning machines, Milling machines, Precision wire cutting machines, more than 160 sets in total

2)Material: iron, carbon steel, stainless steel, brass, copper, alloy steel, aluminum, cold rolled steel with various plating

3)Surface treatment: Black anodizing with brush, and polishing

4)Standard/ specification: OEM service as per customers\' requests, with in-house tooling design & fabricating

5)RoHS compliance for export

6)Quality assurance in accordance with ISO9001:2008

7)Concurrent engineering capability on product design

8)Just-in-time manufacturing capability to meet customer\'s requirement

9)Tailor-made packaging method according to customer\'s requirement

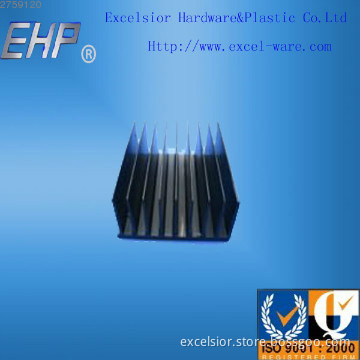

The key factors to high performance aluminum heat sink/exchanger

· High heatsink surface.It\'s at the surface of the heatsink where the thermal transfer takes place. Therefore, heatsinks should be designed to have a large surface; this goal can be reached by using a large amount of fine fins, or by increasing the size of the heatsink itself.

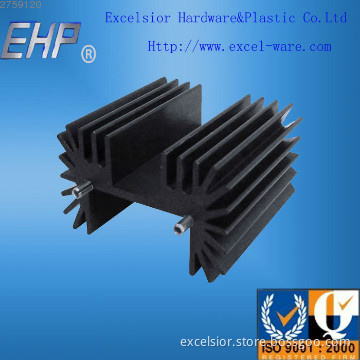

· Good aerodynamics.Heatsinks must be designed in a way that air can easily and quickly float through the cooler, and reach all cooling fins. Especially heatsinks having a very large amount of fine fins, with small distances between the fins may not allow good air flow. A compromise between high surface (many fins with small gaps between them) and good aerodynamics must be found. This also depends on the fan the heatsink is used with: A powerful fan can force air even through a heatsink with lots of fine fins with only small gaps for air flow - whereas on a passive heatsink, there should be fewer cooling fins with more space between them. Therefore, simply adding a fan to a large heatsink designed for fanless usage doesn\'t necessarily result in a good cooler.

· Good thermal transfer within the heatsink.Large cooling fins are pointless if the heat can\'t reach them, so the heatsink must be designed to allow good thermal transfer from the heat source to the fins. Thicker fins have better thermal conductivity; so again, a compromise between high surface (many thin fins) and good thermal transfer (thicker fins) must be found. Of course, the material used has a major influence on thermal transfer within the heatsink. Sometimes, heat pipes are used to lead the heat from the heat source to the parts of the fins that are further away from the heat source.

· Perfect flatness of the contact area.The part of the heatsink that is in contact with the heat source must be perfectly flat. A flat contact area allows you to use a thinner layer of thermal compound, which will reduce the thermal resistance between heatsink and heat source.

· Good mounting method.For good thermal transfer, the pressure between heatsink and heat source must be high. Heatsink clips must be designed to provide a strong pressure, while still being reasonably easy to install. Heatsink mountings with screws/springs are often better than regular clips. Thermoconductive glue or sticky tape should only be used in situations where mounting with clips or screws isn\'t possible.

aluminum heat sink Delivery

DHL, EMS , Fedax availoable , also it could be customized with special design packaging

Additional Information

| Payment Terms | T/T, Western Union, Money Order |

|---|---|

| Minimum Order | 5000 |

| Lead Time / Delivery Time | 5 Day(s) |

| Sample Available | YES |

| Delivery Details | UPS,DHL, Fedax, TNT, Airway, Sea shipment available! |

| FOB Port | Shenzhen |

| Packing Info | Carton box packaging with soft bubble bag |

| Target Market(s) | Eastern Europe, Latin America, Middle East, Northern Europe, Western & Southern Europe |

Related Keywords