HY928 condensation pad print silicone,pad printing silicone rubber

Your message must be between 20 to 2000 characters

Contact NowBasic Specification

| delivery | within 3 fays |

|---|---|

| application | HY928 condensation pad print silicone |

| Certificate | ISO9001,SGS |

| Color | Any color is available |

| MOQ | 200kg |

| Eco-Friendly | Yes |

| Test Report | SGS |

Detail Description

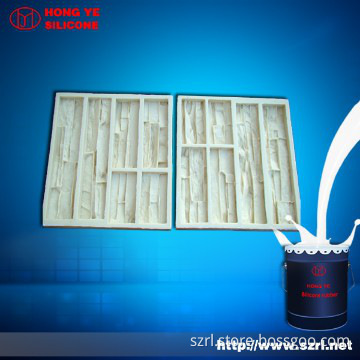

HY928 condensation pad print silicone

pad print silicone is mainly use for printing irregular patterns of plastic toys, electroplating toys and trade makers . pad printing silicone as a carrier which transfer patterns on the steel plate to the toys products surface.

pad print silicone Features:

pad print silicone with high print times and abrasion resistance. pad printing silicone has good printing effects, permanent and durable. We can provide all kinds of color and our catalyst is free.

Models of RTV-2 pad print silicone,

· NO.: HY-912 pad print silicone

· Usage: The best quality in pad print silicone for making pads.

description: HY-912# with the advantages of abrasion resistance, high temperature resistance, good printing effect, etc.The silicon pad is a carrier which transfer printing the patterns on the steel plate onto the toy products\' surface.

Model |

Color |

Mixing ratio (%) |

Pot life (mins) |

Demould time ( hrs) |

Hardness ( A0 ) |

Tensile-strength (Mpa) |

Tear-strength (KN/m) |

Viscosity (cps) |

Shrinkage rate (%) |

Elongation (%) |

912 |

Green |

100: 3 |

45 |

6-7h |

28±2 |

≥ 42 |

≥ 26 |

21000 |

≤0.3 |

400 |

HY928 condensation pad print silicone condensation pad print silicone condensation pad print silicone

FAQ:Why the silicon pad can not transfer the printing pattern well?

It is normal phenomena that every two out of ten products have this problem if the plastic toys are not spray painted. As in the production process, mold release agent will be sprayed onto the surface of the steel plate for each one dozen products, and there will be some mold release agent left on the surface of the first one or two product. Please use Tianna water or face-clean water to clean the products before used for pad printing.

Need any help on silicone rubber, please feel free to contact Ms Maggie

Tel:86-755-89212369

Mob:86-13828847574

E-mail: maggie822014(at)gmail(dot)com

Skype:maggie.cao82

Additional Information

| Payment Terms | L/C, T/T, Western Union, Others |

|---|---|

| Minimum Order | 100 kgs |

| Lead Time / Delivery Time | 3 Day(s) |

| Sample Available | YES |

| Delivery Details | By sea |

| FOB Port | Shenzhen |

| Loading Info | FOB, CNF or CIF |

| Packing Info | 5kg/drum, 20kg/drum, 25 kg/drum, 200kg/drum Wacker 623 Equal Pad Printing Silicone |

| Target Market(s) | North America, Oceania, Southeast Asia, Eastern Europe, Africa(except Middle East), Hong Kong/ Macao/ Taiwan, Latin America, Japan & Korea, Middle East & South Asia, Mainland China, Western & Southern Europe, Northern Europe, Central & Southern Asia, Middle East |

Related Keywords