HY9 serious pad printing making silicone rubber,rtv silicone

Your message must be between 20 to 2000 characters

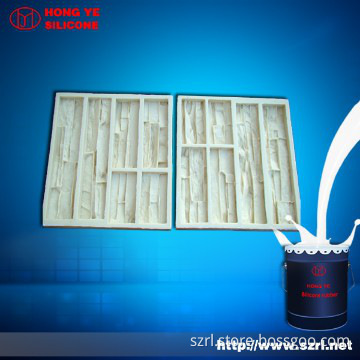

Contact NowBasic Specification

| appearance | liquid silicone |

|---|---|

| color | any |

| application | HY9 serious pad printing making silicone rubber |

| Certifications: | RoHS. MSDS.SGS ISO9001:2000 |

| Supply Ability | 8 Ton per Day |

| Eco-Friendly | Yes |

| Test Report | SGS |

Detail Description

HY9 serious pad printing making silicone rubber

Specifications of HY9 serious pad printing making silicone rubber

Advantages of HY9 serious pad printing making silicone rubber:

1,good printing effects

2,good quality

3,good resilience

4,without any impurity

HY9 serious pad printing making silicone

HY9 serious pad printing making silicone rubber HY9 serious pad printing making silicone rubber

The pad printing silicon rubber usages:

The silicon rubber is mainly use for printing irregular patterns of plastic toys, electroplating toys, trade makers,artwork gifts,stationery,electroplating products etc.Silicon pad printing is a carrier which transfer printing the patterns on the steel plate onto the toys products surface.

HY9 serious pad printing making silicone rubber HY9 serious pad printing making silicone rubber

Pad printing silicon rubber features:

Pad printing silicon rubber with high print times and abrasion resistance, without any inpurities, with good printing effects, permanent and durable,we can provide all kinds of colors are available and our catalyst is free charged.

Pad printing silicon rubber operation instructions:

Pad printing silicon rubber is two-component silicone, part A is the liquid silicon rubber, part B is the catalyst. The usual mxing ratio for silicone rubber and catalyst is two to three percent, eg. we take one hundred grams of liquid silicon rubber,then we add two to three grams catalyst, mix then evenly and pour it to your mold. Then after two to four hours, you will obtain a printing pad.

HY9 serious pad printing making silicone rubber HY9 serious pad printing making silicone rubber

HY9 serious pad printing making silicone rubber HY9 serious pad printing making silicone rubber

Frequently asked question of pad printing silicon rubber:

The reasons why the silicon pad has a short service life are listed as follows:

(1)The problem caused by inappropriate filtration of silicone rubber, and impurities in the packaging process due to the uncleanness of barrels and bags.

(2)The short service life of the silicone pad has a close relationship with the adding amount of silicone oil. The more the silicone oil added, the softer the silicone pad will be. The silicone oil will destroy the molecule of the silicone rubber, thereby bringing about the non-durable and easy ageing of the silicone pad.

(3)All the users should know the properties of pad printing silicone rubber. The service life of the silicone pad has close relationship with the size of the printed patterns. For example, if a big pattern to be printed, a big silicone pad is required; if a small pattern to be printed, a small silicone pad (the silicone pad has to be adjusted according to the size of the patterns, and the proportion between the size of the silicone pad and the pattern is three to one.)

HY9 serious pad printing making silicone rubber HY9 serious pad printing making silicone rubber

Need any help on silicone rubber, please feel free to contact Ms Maggie

Tel:86-755-89212369

Mob:86-13828847574

E-mail: maggie822014(at)gmail(dot)com

Skype:maggie.cao82

Additional Information

| Payment Terms | L/C, T/T, Western Union |

|---|---|

| Minimum Order | 200kg |

| Lead Time / Delivery Time | 3 Day(s) |

| Sample Available | YES |

| Delivery Details | Within three days after getting your payment |

| FOB Port | Shenzhen |

| Loading Info | shenzhen port by sea |

| Packing Info | 25kg and 100kg per drum |

| Target Market(s) | North America, Oceania, Southeast Asia, Eastern Europe, Africa(except Middle East), Hong Kong/ Macao/ Taiwan, Latin America, Japan & Korea, Mainland China, Western & Southern Europe, Northern Europe, Central & Southern Asia, Middle East |

Related Keywords