silicone rubber for shoe mold making,cast shoe mold manufacturer

Your message must be between 20 to 2000 characters

Contact NowBasic Specification

| application | silicone rubber for shoe mold making |

|---|---|

| hs code | 3910 0000 |

| operation way | by brushing or pouring |

| color | white |

| sample | free |

| Eco-Friendly | Yes |

| Test Report | SGS |

Detail Description

1.Application:

silicone rubber for shoe mold making is mainly used for shoe molds, sand casting, Shoe soles mold, sand casting,brushing mold,plaster models, simple products, products with non-complex patterns, as well as product models with stable size and non-deformation.

2.Specification:

1. silicon for shoe mold making with good aracteristics of easy-operation

2. Light viscosityand good fluidity of silicon for shoe mold making

3. Low shrinkage of silicon for shoe mold making

4. Favorable tension of silicon for shoe mold making

5. No deformatio of shoe soles molding silicon

6. Favorable hardness of silicon for shoe mold making

7. High temperatureresistance, acid and alkali-resistance and ageing resistanc

3.Datasheet:

Model |

Color |

Mixing ratio (%) |

Pot life (mins) |

Demould time ( hrs) |

Hardness ( A0 ) |

Tensile-strength (kgf/cm2) |

Tear-strength (kgf/cm) |

Viscosity cps |

Shrinkage rate (%) |

Elongation % |

208# |

100 : 2 |

30 |

2-4 |

25-30 |

≥ 10 |

≥ 8 |

15000 |

≤0.3% |

200% |

|

218# |

100 : 2 |

30 |

2-4 |

20 |

≥ 8 |

≥ 4 |

7000-8000 |

≤0.3% |

200% |

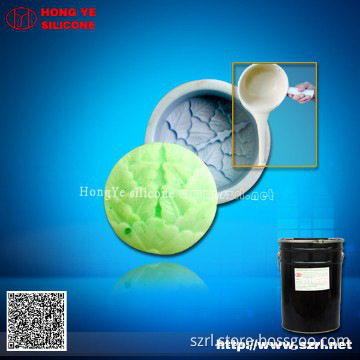

4.Picture show:

5.Using Instruction:

The component A of silicone rubber for shoe mold making is white flowing liquid and the component B is the curing agent. For example, take silicone rubber of 100g and add 2% curing agent for mixing evenly. After the silicone rubber and the curing agent are completely mixed, put the silicon into a vacuum machine for deairing to remove the bubbles. After deaired, pouring the liquid silicone rubber into the product to be duplicated or into the mold frame.

6.Notes:

silicone rubber for shoe mold making is used for pouring or brushing technique. That is to say, fix the product or sole model to be duplicated onto a plane plate, then enclose the plane frame with wooden plates to prevent the leakage of the silicon , mix the silicone rubber and the curing agent evenly according to the mixing ratio of 100 : 2 and pour them onto the sole model, then brush evenly with a wooden plate or a brush, and fill up the mold frame with gypsum after the silicone rubber is dried

Need any help on silicone rubber, please feel free to contact Ms Maggie

Tel:86-755-89212369

Mob:86-13828847574

E-mail: maggie822014(at)gmail(dot)com

Skype:maggie.cao82

Package:

Certification:

About us:

Additional Information

| Payment Terms | L/C, T/T, Western Union |

|---|---|

| Minimum Order | 200 |

| Lead Time / Delivery Time | 3 Day(s) |

| Sample Available | YES |

| Delivery Details | we will delivery the goods after we confirmed your payment |

| FOB Port | Shenzhen |

| Loading Info | CIF to the port you pointed |

| Packing Info | 5kg/drum 25kg/drum 200kg/drum manufacture of RTV 2 silicone rubber for mould making |

| Target Market(s) | North America, Oceania, Southeast Asia, Eastern Europe, Africa(except Middle East), Hong Kong/ Macao/ Taiwan, Latin America, Japan & Korea, Middle East & South Asia, Mainland China, Western & Southern Europe, Northern Europe, Central & Southern Asia, Middle East |

Related Keywords