Silastic 3481 silicone rubber

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

Product Description

Product Description

Basic Specification

| certificate | SGS, MSDS, RoHS |

|---|---|

| Model Number | 625# RTV silicon rubber |

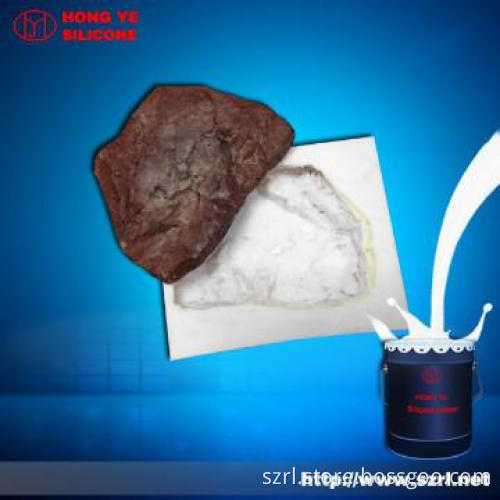

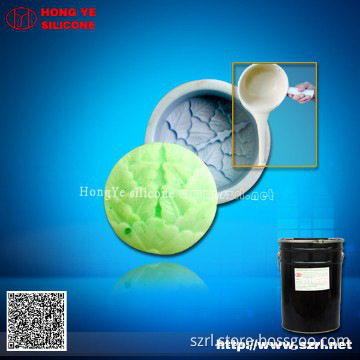

| Application | for sculpture ,gypsum mold ,rock mold ,etc |

| Brand Name | HONG YE SILICON RUBBER |

| Appearance | liquid |

| Eco-Friendly | Yes |

| Test Report | SGS |

Detail Description

Applications of Silastic 3481 silicone rubber

Silastic 3481 silicone rubber is primarily intended for poly resin crafts,PU crafts,PU resin crafts ,gypsum crafts ,unsaturated resin crafts, lighting and candles crafts ,plastic toy , stationery gifts crafts industry, a large statue Buddha, relievo furniture, furniture decorative materials, statues Buddha, artifacts copied, building decoration materials, large-scale cement mold, artificial fossils Factory,Europe component factory, simulation landscapes, animals and plants sculpture, sandstone crafts and so on.

Features of Silastic 3481 silicone rubber

Silastic 3481 silicone rubber is white or red flowing liquid with general hardness of 22-50shore A after curing. Molding silicone rubber is a kind elastic silicone rubber mold which features with resistance to deformation, high-temperature, acid-alkali and expansion as well as high reproduction times, good tensile strength ,tear strength and elongation.

Why does the silicone mold get burnt out?

The unsaturated resin produces great heat when added the curing agent. So you must demould the product within 3 minutes to avoid this problem.

Data sheet of Silastic 3481 silicone rubber( Silicone Rubber)

Model |

Color |

Mixing ratio (%) |

Pot life (mins) |

Demould

time

( hrs)

|

Hardness ( A0 ) |

Tensile-strength |

Tear-strength |

Viscosity

(mPas)

|

Shrinkage

rate (%)

|

Elongation

(%)

|

HongYe625# |

white |

100 : 5 |

45-60 |

4-6 |

23-26 |

45kgf/cm2 |

≥ 29kgf/cm |

20000 |

≤0.3% |

450% |

HongYe630# |

white |

100 :5 |

30-40 |

3-5 |

29-31 |

49kgf/cm2 |

≥ 33kgf/cm |

26000 |

≤0.3% |

490% |

Dowcorning3481 |

white |

100 : 5 |

30-45 |

5-6 |

22-25 |

4.6Mpa |

23kN/m |

25000 |

≤0.5% |

520% |

Bluestar (3325 /585) |

white |

100 : 5 |

20-60 |

6-24 |

25-28 |

4.2Mpa |

26kN/m |

35000 |

≤0.7% |

440% |

Wacker®M4503 |

white |

100 : 5 |

30-90 |

10-20 |

25 |

5.0(N/mm² |

> 20N/mm |

40000 |

≤0.5% |

350% |

SmoothonMoldMax®25 |

white |

100 : 5 |

45 |

24 |

25 |

577psi |

130pli |

25000 |

002 in./in |

Additional Information

| Payment Terms | L/C, T/T, Credit Card, Western Union |

|---|---|

| Minimum Order | 200KG |

| Lead Time / Delivery Time | 6 Day(s) |

| Sample Available | YES |

| Delivery Details | FOB, CFR, CIF etc. |

| FOB Port | Shenzhen |

| Loading Info | BY Sea or By Air |

| Packing Info | 25KG/PAIL |

| Target Market(s) | North America, Oceania, Southeast Asia, Eastern Europe, Africa(except Middle East), Hong Kong/ Macao/ Taiwan, Latin America, Japan & Korea, Middle East & South Asia, Mainland China, Western & Southern Europe, Northern Europe, Central & Southern Asia, Middle East |

Related Keywords

Related Keywords