RTV-2 Addition cure silicone rubber for concrete mold making

Your message must be between 20 to 2000 characters

Contact NowBasic Specification

| Color | translucent |

|---|---|

| application | RTV-2 Addition cure silicone rubber for concrete |

| Operation way | by brushing or pouring |

| hs code | 39100000 |

| Sample | free |

| Eco-Friendly | Yes |

| Test Report | SGS |

Detail Description

Description

RTV-2 Addition cure silicone rubber for concrete mold making are generally named as twopart addition silicone rubber that vulcanises at room temperature.Part A is a flowable liquid, part B is the curing agent(platinum catalyst). It features an exceptional fluidity ,good operability,excellent physical properties and very low shrinkage.The mixing ratio between Part A and Part B can be 10:1 or 1:1.

Main application

· Concrete mold

· GRC and Concrete moulding

· PU resin casting

· General Mouldmaking

· Superior manual mold design

Main properties

· high chemical resistance to aggressive components of some types of resins

· good tear strength (this feature ensures higher resistance to wearing and shearing)

· high degree of precision in reproduction

· high dimensional stability over time and non-deformability

· high resistance to high temperatures and ageing (resit to -60-200°C)

· excellent non-stick effect

· environmental, odorless and nontoxic

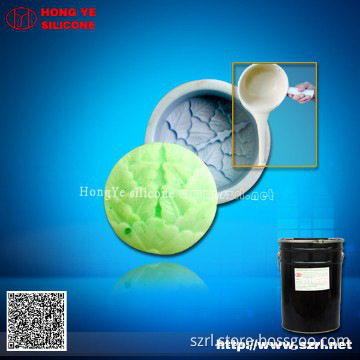

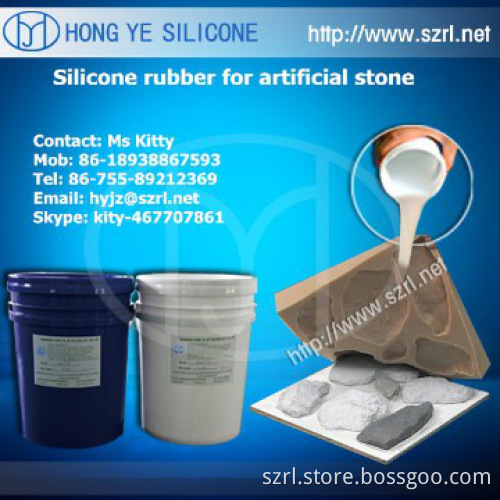

Picture show

Datasheet (25°C)

Product |

E-630 |

Appearance |

Translucent |

Hardness(shore A) |

30±2 |

Mix ratio(A:B) |

1:1or 10:1 |

Viscocity Part A(mPa.s) |

20000±2000 |

Viscocity Part B(mPa.s) |

2400±500 |

Tensile strength (MPa) |

7.2 |

Tear-strength (kN/m) |

24 |

Elongation(%) |

440 |

Density |

1.13 |

Pot life/working time (mins) |

30-40 |

Curing time/setting time (hrs) |

3-4hrs(25°C) 20-30mins(60°C) |

Shrinkage rate (%) |

0.1 |

Operation way

Step One: Take 100g of part A and add 100g of part B and mix the silicon rubber and the curing agent evenly.

Step Two: vacuum pumping

Without exception, this takes less than 10 minutes. Otherwise, it will cause cross linking reaction, and no more further steps will be available.

Step Three: Brushing cast & Perfusion Molding operation.

Package

For more information, please fell free to ask Mr. Tony

Tel:86-755-89948006

Mob:86-18938867516

e-mail: hyi(at)szrl(dot)net

Skype: kimberly_802

Additional Information

| Payment Terms | L/C, T/T, D/P, Western Union, Paypal |

|---|---|

| Minimum Order | 200kg |

| Lead Time / Delivery Time | 4 Day(s) |

| Sample Available | YES |

| Delivery Details | within three days after getting your payment |

| FOB Port | Shenzhen |

| Loading Info | FOB Shenzhen port by sea |

| Packing Info | 25kg and 200kg per drum Molding Silicoen Rubber for Concrete Casting |

| Target Market(s) | North America, Oceania, Southeast Asia, Eastern Europe, Africa(except Middle East), Hong Kong/ Macao/ Taiwan, Latin America, Japan & Korea, Middle East & South Asia, Mainland China, Western & Southern Europe, Northern Europe, Central & Southern Asia, Middle East |

Related Keywords