Molding silicone rubber for GRC products,rtv silicone rubber

Your message must be between 20 to 2000 characters

Contact NowBasic Specification

| application | Molding silicone rubber for GRC products |

|---|---|

| Appearance | liquid material |

| HS | 31900000 |

| Sample | free |

| operation way | by brushing or pouring |

| Eco-Friendly | Yes |

| Test Report | SGS |

Detail Description

Application

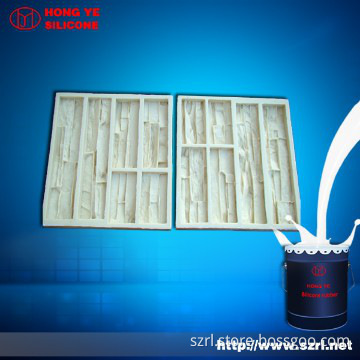

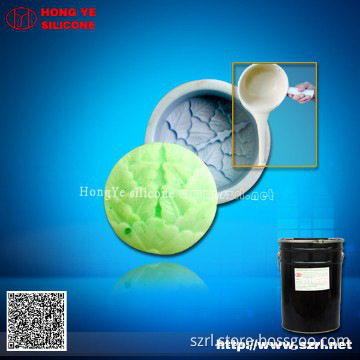

Molding silicone rubber for GRC products,rtv silicone rubber is application for plastic toys, relieve furniture,architectural decoration, funiture decorative,sculpture, art crafts mold making and so on.It is a two-part silicone rubber; It has an easy release, high elongation, minimal shrinkage, long work time.

Feature

Molding Silicone Rubber for GFRC Columns is generally named two -component room temperature vulcanization silicone rubber, a kind elastic silicone rubber mold which features with resistance to deformation, high-temperature, acid-alkali and expansion

Picture

Datasheet

Model |

630# |

Appearance |

white |

Mixing proportion of curing agent (%) |

5% |

Operating time (mins 25 0C ) |

20-40 |

Curing time(hours 25 0C) |

3-5 |

Hardness (A°) |

30±2 |

Density ( g/cm 3 ) |

1.08 |

Viscosity (Mpas -25 0C) |

27000-32000 |

Tensile-strength(kgf /cm2 ) |

≥40 |

Tear-strength (kgf /cm ) |

≥30 |

Elongation-break(%) |

≥ 450 |

Retractility(%) |

≤0.3 |

Instruction

Molding silicone rubber for GRC products are generally named as two-part room temperature sulfurated silicone rubber, which features an exceptional fluidity and good operability. When mixed with 2-3% curing agent, they can still be operated within 30 minutes, but will be formed after 2-3 hours. With resistance to deformation, high temperature, acid and alkali, and expansion, silicon flexible molds are used for mold duplication and delicate mold making for poli crafts, resin crafts lighting and candle crafts.

Storage and precaution

Molding silicone rubber for GRC products which is an environmentally-friendly liquid silicone product, is not easy to burn and can be stored and transported as non-hazardous goods. The shelf life of the product is about one year from the date of production. Inspection is required when exceeding the time limited. It can continue to be used in case of neither thickening nor deterioration.

FAQ

Why does the silicone mold get burnt out?

This consequence happens only because you have left out the important notes when using unsaturated resin materials to produce your products. The unsaturated resin produces great heat when added the curing agent. So you must demould the product within 3 minutes to avoid this problem.

Certification

ISO9001: HK05/01358

SGS:GZ0606100461/CHEM

RoHS:BTRS091718751

Patent:ZL200520001597.8

Need any help on silicone rubber, please feel free to contact Ms Kitty:

Tel:86-755-89212369

Mob:86-18938867593

E-mail: hyjz(at)szrl(dot)net

Skype:kity-467707861

About us:

We are manufacturer specializing in molding silicone rubber, mold duplicating rubber for resin craft makers, special silicon for manual molding, shoe mold rubber, pad printing silicone, encapsulants and potting compound,addition cure liquid silicone,baby nipple silicone rubber ,lifecasting,food grade silicone rubber, trademark silicone rubber, HTV silicone rubber, lead-zinc alloy crafts silicone rubber, hot stamping silicone plate, hot stamping silicone roller, gross rubber, RTV-2 silicone rubber, silicone molds, silicone products,etc.

Additional Information

| Payment Terms | L/C, T/T, Western Union |

|---|---|

| Minimum Order | 200kg |

| Lead Time / Delivery Time | 3 Day(s) |

| Sample Available | YES |

| Delivery Details | within 3 days after payment confirmed in our bank. |

| FOB Port | Shenzhen |

| Loading Info | by shipping |

| Packing Info | 25kg/drum and 200kg/drum |

| Target Market(s) | North America, Oceania, Southeast Asia, Eastern Europe, Africa(except Middle East), Hong Kong/ Macao/ Taiwan, Latin America, Japan & Korea, Middle East & South Asia, Mainland China, Western & Southern Europe, Northern Europe, Central & Southern Asia, Middle East |

Related Keywords