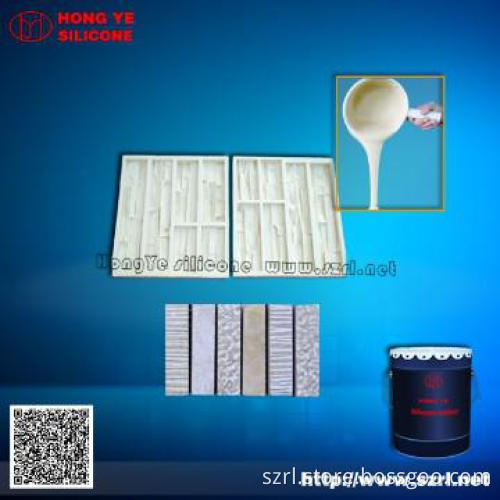

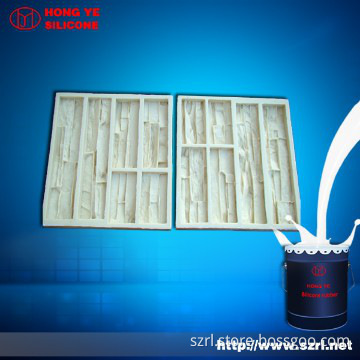

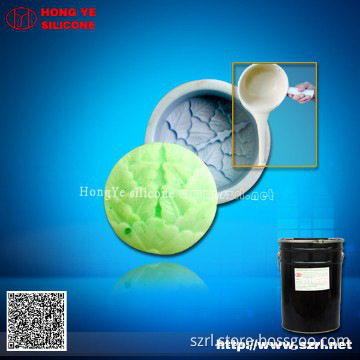

RTV silicone material for concrete/cement molds making,liquie silicon

Your message must be between 20 to 2000 characters

Contact NowBasic Specification

| Curing Agent | 5%for free charged |

|---|---|

| Application | Mold making materials |

| Color | White(different colors are available if requested |

| Usage | for many produce mold making in pouring way |

| Classification | Chemical Auxiliary Agent |

| Product Material | Rubber |

| Shaping Mode | Silicone Mould |

Detail Description

RTV silicone material for concrete/cement molds making

RTV silicone material for concrete/cement molds making can be used for production of different sizes of polyurethane moulds,gypsum moulds,plaster moulds, resin moulds,polyresin moulds,PU resin moulds,wax moulds,stone moulds ,epoxy moulds,acrylic moulds,polyester moulds making

A. Decorative items: cornices moulding ,columns moulding,ornaments moulding,statues molding.....

B. Casting of funiture and decoration crafts molding

C. Construction: prefabrication of decrative features molding,pavement molding,paving stone moulding,urban

furniture molding,concrete products molding

D. Soap moulding,candles crafts moulding,toys moulding,sculpture moulding

2 RTV silicone material for concrete/cement molds making features

1. Good characteristics of easy-operation

2. Light viscosity and good flowability

3. Low shrinkage

4. Excellent tensile and tear strength

5. Favorable hardness

6. High temperature resistance, acid and alkali-resistance and ageing resistance

7. High duplication times

3. RTV silicone material for concrete/cement molds making TDS:

Model |

HY630 |

Appearance |

Liquid |

Mixing ratio |

100:5 |

Operating time (mins 25 0C ) |

40-70 |

Curing time(hours 25 0C) |

4 |

Hardness (A°) |

28±2 |

Density ( g/cm 3 ) |

1.08 |

Viscosity (Mpas -25 0C) |

24000±3000 |

Tensile-strength(kgf /cm2 ) |

≥45 |

Tear-strength (kgf /cm ) |

≥28 |

Elongation-break(%) |

≥ 500 |

Retractility(%) |

≤0.25 |

Shelf life (month) |

≥12 |

4. RTV silicone material for concrete/cement molds making frequently asked question:

Why does the silicone rubber molds appeared striately and unsmoothly?

It is because the appearance of the product or the model itself is not perfect, and it has not been polished before the further operation. So when you make silicon molds, firstly you should polish the product, spray the mold spray evenly on the product. In this case, the problem can be avoided.

5.To recommend suitable product for your application, we would be much appreciated to have your following information:

1. What is the material of your product?

2. What is the size of your product?

3. How do you make silicone mold, by pouring or brushing?

SHELF LIFE of RTV silicone material for concrete/cement molds making:

Twelve (12) months from date of shipment when stored at 24°C in original unopened packages.

PACKAGE of RTV silicone material for concrete/cement molds making:

Packed in clean 25kg/pail, 200kg/pail.

Need any help on silicone rubber, please feel free to contact Ms Maggie

Tel:86-755-89212369

Mob:86-13828847574

E-mail: maggie822014(at)gmail(dot)com

Skype:maggie.cao82

Additional Information

| Payment Terms | L/C, T/T, Others |

|---|---|

| Minimum Order | 200kg |

| Lead Time / Delivery Time | 6 Day(s) |

| Sample Available | YES |

| Delivery Details | Wthin 3 days after payment confirmed in our bank. |

| FOB Port | Shenzhen |

| Loading Info | by ship or by air |

| Packing Info | 5KG/Drum 25KG/Drum 200KG/Drum |

| Target Market(s) | North America, Oceania, Southeast Asia, Eastern Europe, Africa(except Middle East), Hong Kong/ Macao/ Taiwan, Latin America, Japan & Korea, Mainland China, Western & Southern Europe, Northern Europe, Central & Southern Asia, Middle East |

Related Keywords